Filler wall with herringbone ladder rebars inlaid and construction method of filler wall

A technology of ladder grid reinforcement and filling walls, which is applied to walls, building components, and earthquake resistance. It can solve the problems of underutilized strength of filling walls, complex stress of filling walls, and poor frame connections, etc., to achieve improved earthquake resistance and energy dissipation. The effect of increasing diagonal braces and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

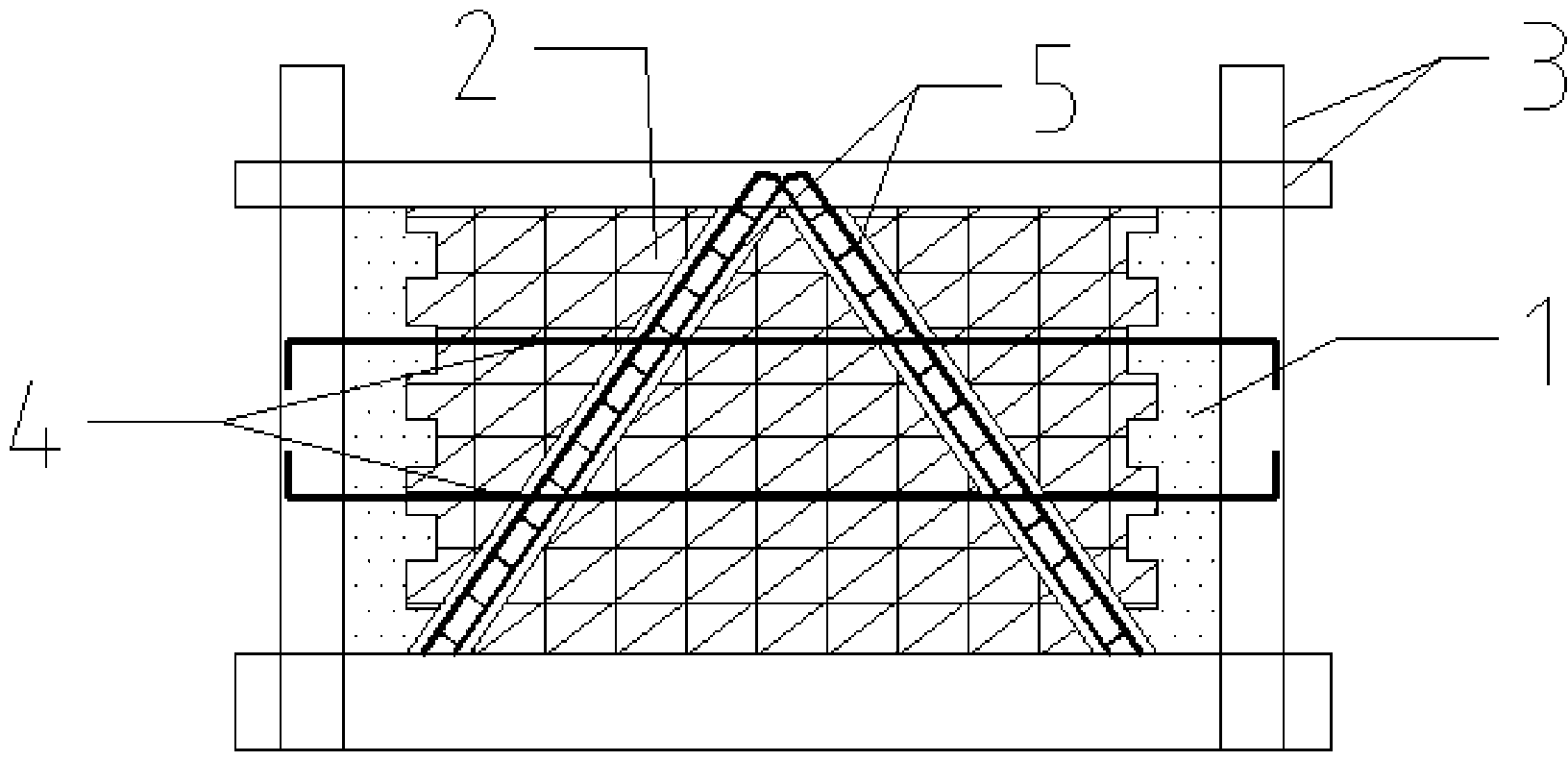

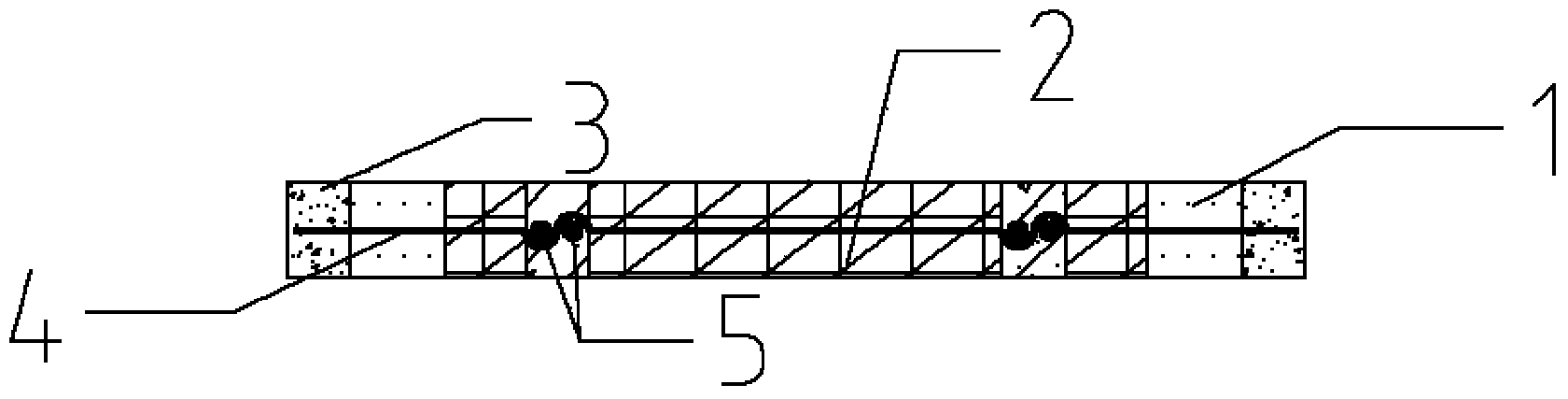

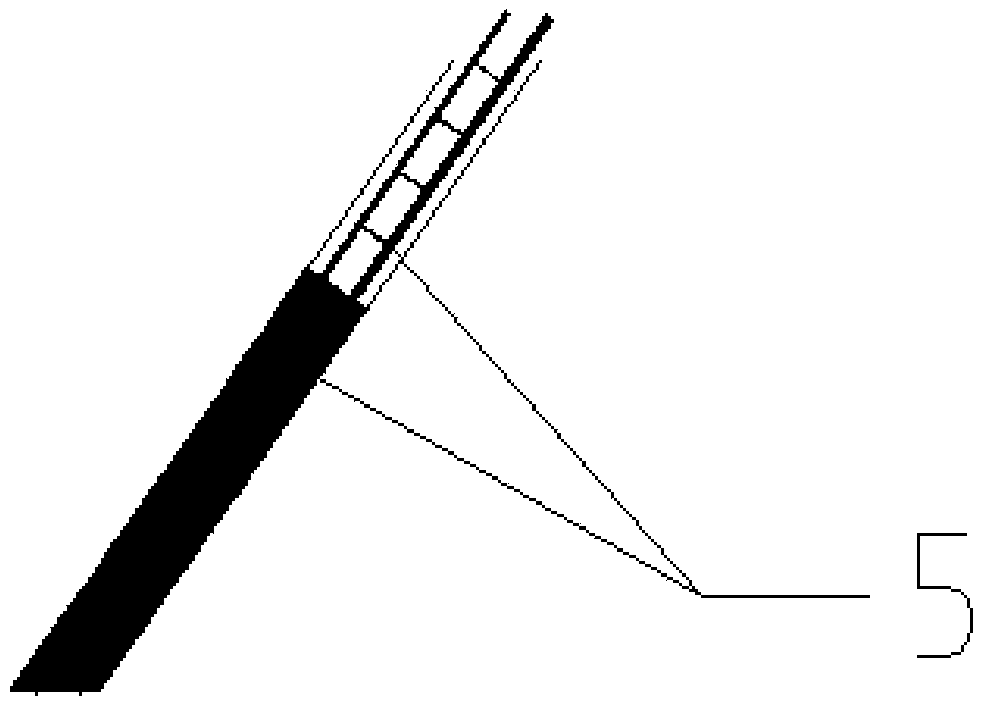

[0026] The built-in herringbone ladder grid steel bar filling wall is mainly composed of energy dissipation strips 1, concrete blocks 2, concrete frame 3, reserved tension bars 4, ladder grid steel mesh braces 5; the concrete frame 3 is an ordinary concrete structure Or recycled concrete structure, there are vertical energy dissipation strips 1 on both sides of the frame filling wall; the energy dissipation strip 1 and the concrete block 2 are connected by horse-toothed bars; the frame columns of the concrete frame 3 are reserved for tension reinforcement 4. The diagonal brace 5 of the ladder grid steel mesh is herringbone, and the diagonal brace 5 of the ladder grid steel mesh is located in the concrete frame 3, and the herringbone opening is located at the lower end of the concrete frame 3; the diagonal brace 5 of the ladder grid steel mesh and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com