Infilled wall with build-in cross steel bars and manufacturing method of infilled wall

A technology of infill walls and steel bars, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of insufficient use of the infill wall strength, complex force of the infill wall, poor frame connection, etc., to improve the seismic energy dissipation, increase the slope The effect of supporting and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

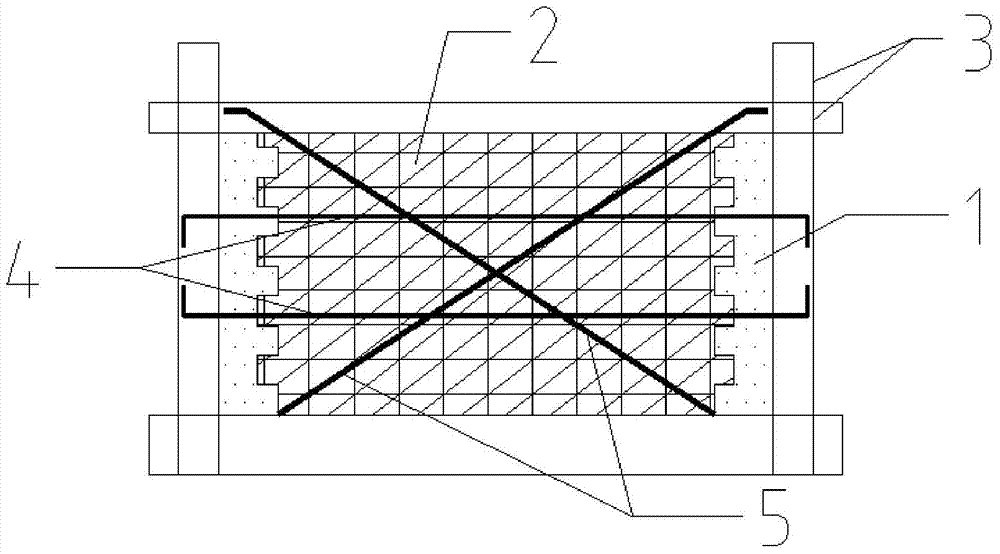

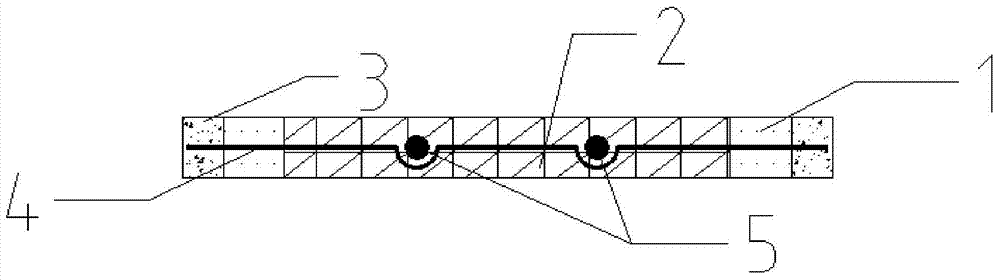

[0025] Built-in cross-reinforcement filled wall, mainly composed of energy-dissipating strips 1, concrete blocks 2, concrete frame 3, reserved tension bars 4, and cross-bars 5; its feature is that the concrete frame 3 is ordinary concrete structure or recycled concrete There are vertical energy-dissipating strips 1 on both sides of the frame filling wall; the energy-dissipating strips 1 and the concrete blocks 2 are connected with horse-toothed bars; 5 is X-shaped, and the cross reinforcement 5 is located at the diagonal position of the concrete frame 3; after the simultaneous construction of the cross reinforcement 5 and the concrete frame (3) is completed, the concrete block 2 is formed by masonry; The tension bars in the concrete block 2 are connected; after the concrete frame 3 is poured, the wall is built by layers with the energy dissipation st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com