Manufacturing method of steel for speed reducer gear of electric automobile

A technology for electric vehicles and manufacturing methods, applied in the direction of improving process efficiency, can solve the problem of high production cost, and achieve the effects of small stress concentration, high strength, and uniform plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

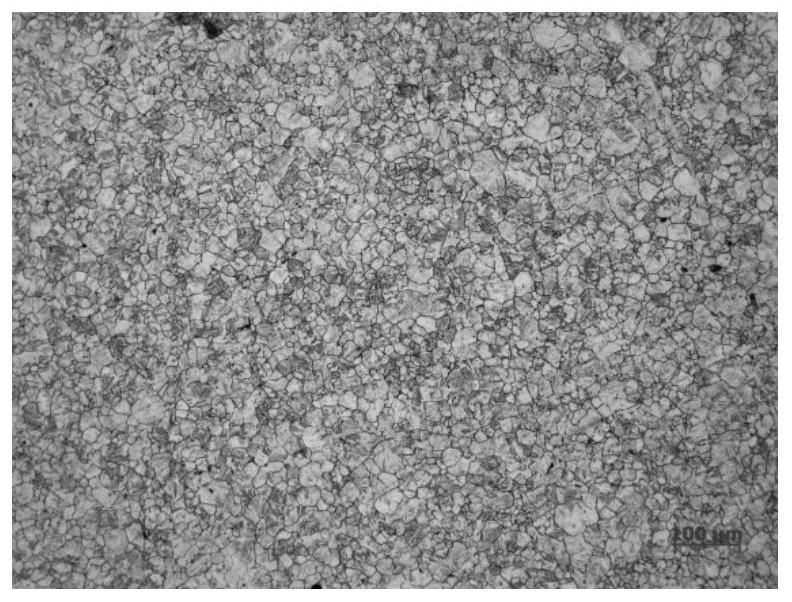

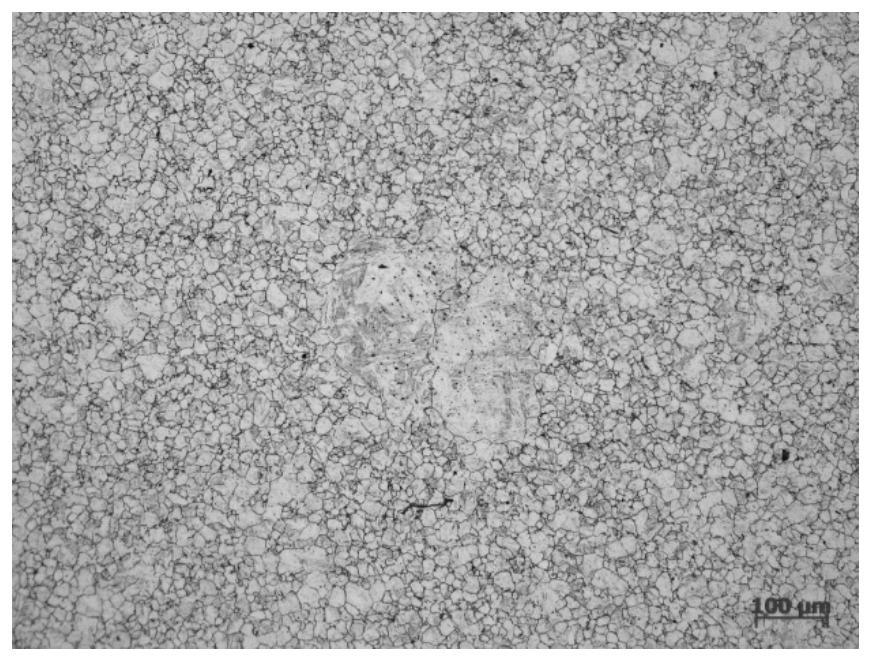

Image

Examples

Embodiment 1

[0046] The concrete steps of embodiment 1 and comparative example 2 are:

[0047] 1. Steelmaking

[0048] 1) The primary smelting furnace selects high-quality molten iron, and the proportion of high-quality molten iron is 20-60%; the rest is high-quality scrap steel. During the primary smelting process, the relationship between the amount of oxygen blown into the molten steel and the heat supply is controlled: the amount of oxygen blown per ton of steel is 50 Cubic meters -85 cubic meters, the power supply per ton of steel is 150-400 degrees.

[0049] , reduce P and residual elements in molten steel.

[0050] 2) Control of key points in the smelting and tapping process of the primary furnace: focus on controlling the carbon at the end of the primary furnace tapping to not less than 0.05% to prevent over-oxidation of molten steel.

[0051] 3) LF furnace refining: After the LF furnace is powered on, argon gas is blown at the bottom of the whole process, and the deoxidation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com