Electric arc preheating repair welding method for stir friction plug

A technology of friction stir welding and friction stir, which is applied in the direction of non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of broken stirring needles, reduced mechanical properties of joints, poor continuous fluidity of materials, etc., to ensure one-time forming, High process stability and reproducibility, low weld residual stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

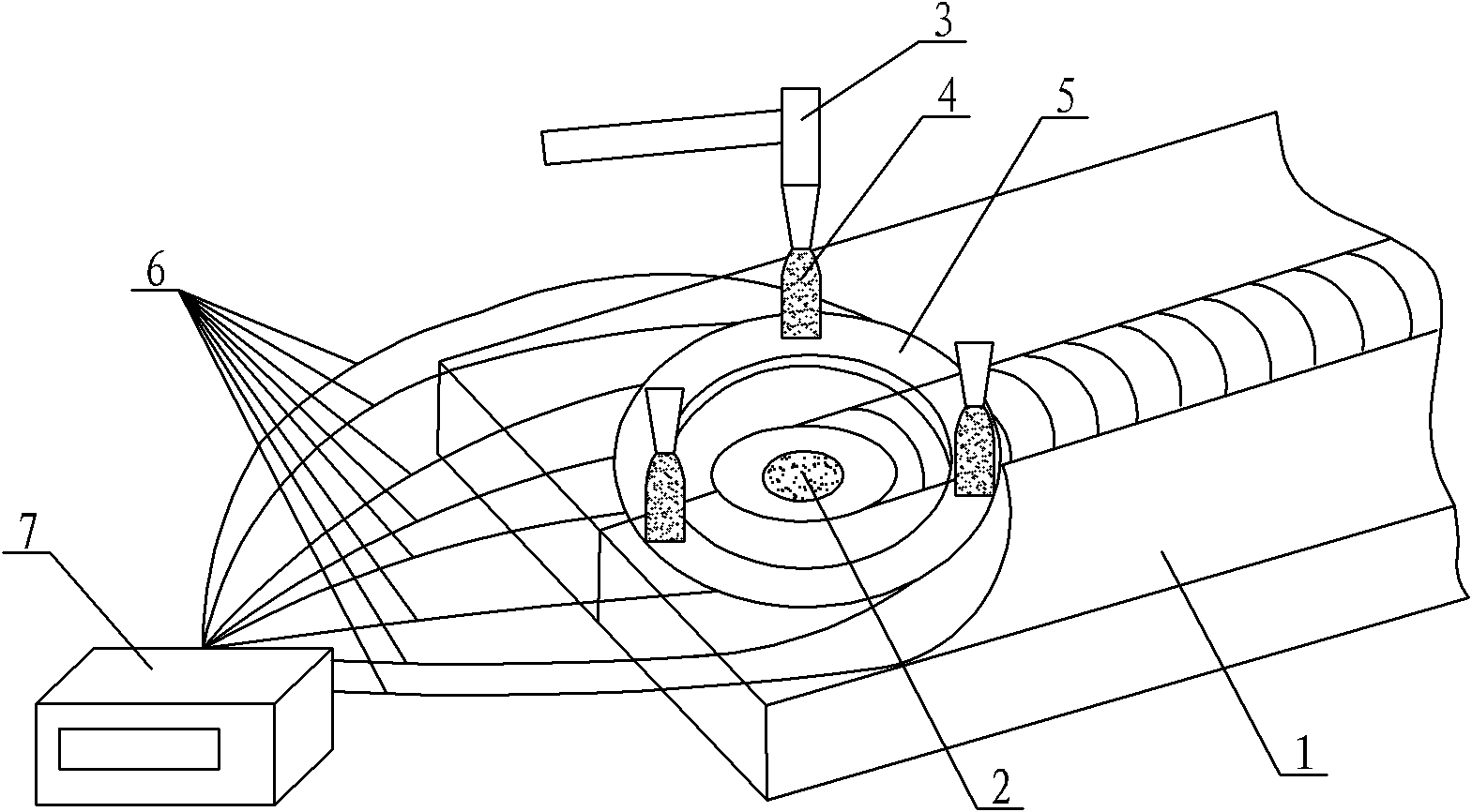

[0011] Specific implementation mode one: combine figure 1 Describe this embodiment mode, this embodiment mode is realized through the following steps: Step 1, carry out arc preheating to the keyhole left over during friction stir welding or secondary friction stir welding repair: place the circular ring 5 made of copper on stirring horizontally On the keyhole part left by friction welding, and the center of the ring 5 coincides with the center of the keyhole. The central aperture of the ring 5 should be larger than the aperture of the keyhole. The ring 5 is heated by arc, and the heating temperature is 180°C-220°C. After the ring 5 is heated, the heat is transferred to the area to be repaired, so that the keyhole of the area to be repaired is preheated. The ideal preheating temperature is 180°C-220°C. If the temperature is higher than the ideal preheating temperature, stop the arc heating immediately; if the temperature is lower than the ideal preheating temperature, start the...

specific Embodiment approach 2

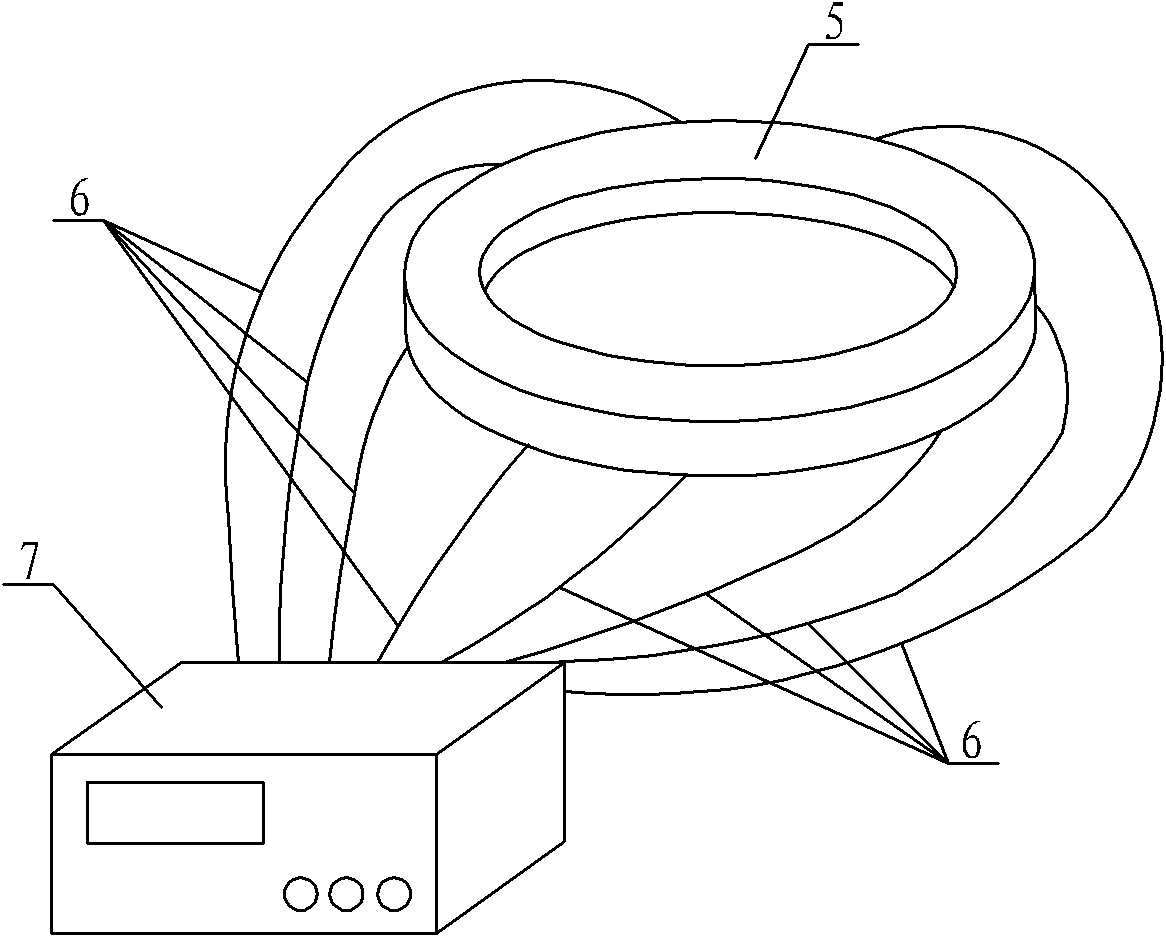

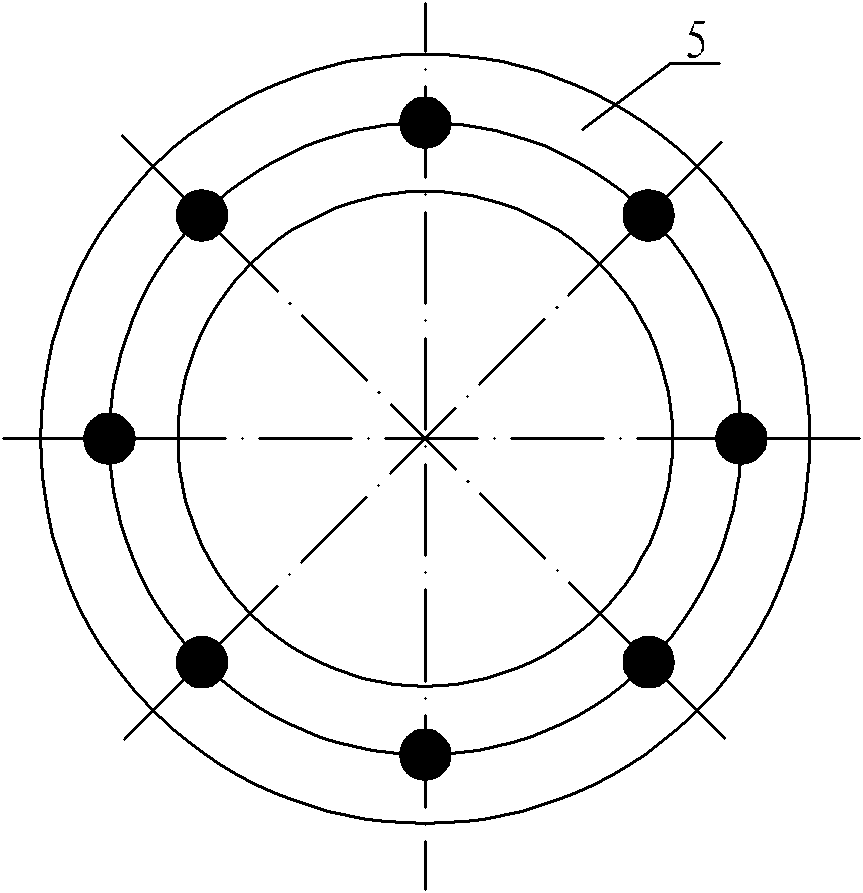

[0012] Specific implementation mode two: combination figure 2 and image 3 To illustrate this embodiment, the arc heating system in step one of this embodiment is composed of argon tungsten arc welding machine, ring 5, eight thermocouples 6 and eight-channel thermometer 7, the argon tungsten arc welding machine The welding gun head 3 is aligned with the upper surface of the ring 5, one end of the eight thermocouples 6 is connected to the eight-channel thermometer 7, and the other ends of the eight thermocouples 6 are evenly placed on the contact surface between the ring 5 and the workpiece , placed in a position such as image 3 As shown, the heat of the arc is conducted to the area to be repaired through the ring 5 to realize the indirect preheating of the arc. The thermocouple 6 monitors the temperature of the preheating area in real time to realize the control of the preheating temperature. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the heating of the ring 5 in Step 1 of this embodiment can be performed by single arc heating or multi-arc heating. Single arc heating is to use a welding torch to make circular motion on the upper surface of the ring 5 to form a single arc for uniform heating; multi-arc heating is to use two to eight welding torches to distribute evenly on the upper surface of the ring 5 and synchronize them on the upper surface of the ring 5. Make a circular motion on the upper surface of the machine to form multiple arcs to achieve sufficient and uniform preheating of the area to be repaired. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com