Method for performing diffusion welding of aluminum base alloy and titanium alloy after laser melting

A technology of laser fusion and diffusion welding, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of increasing the difficulty of connection process parameter selection and process implementation, and achieve good connection effect, Effect of grain structure refinement and reduction of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

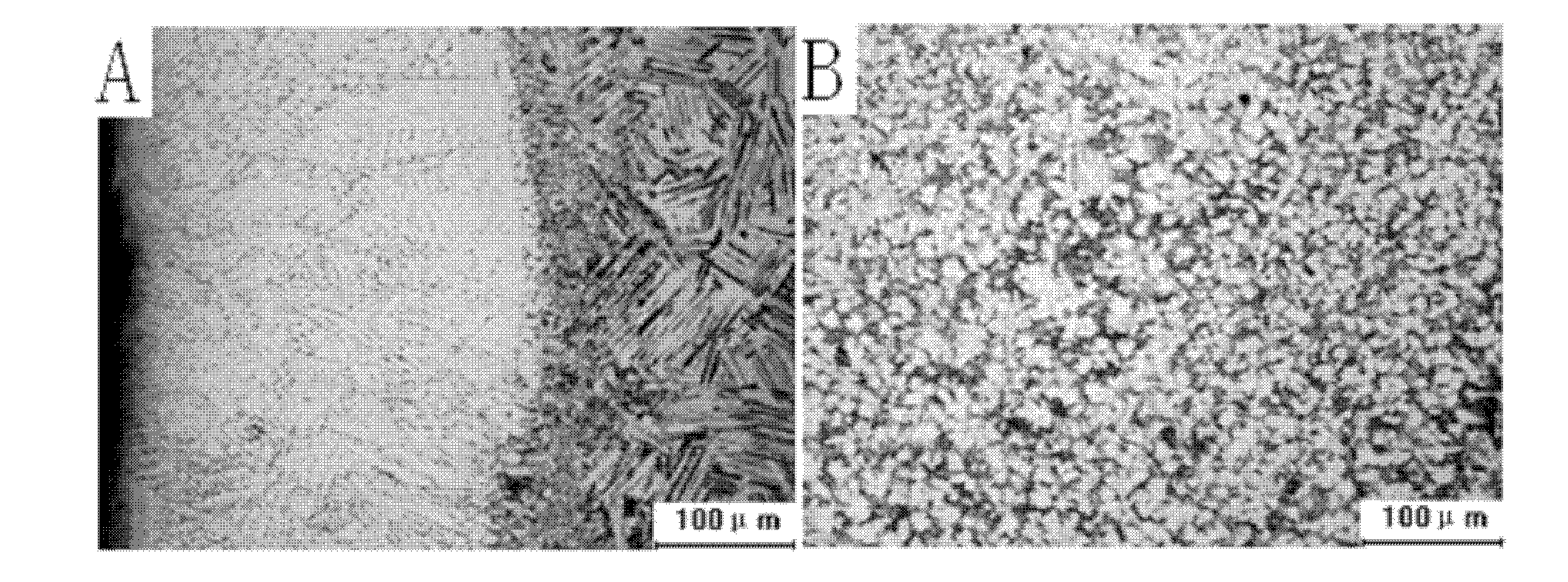

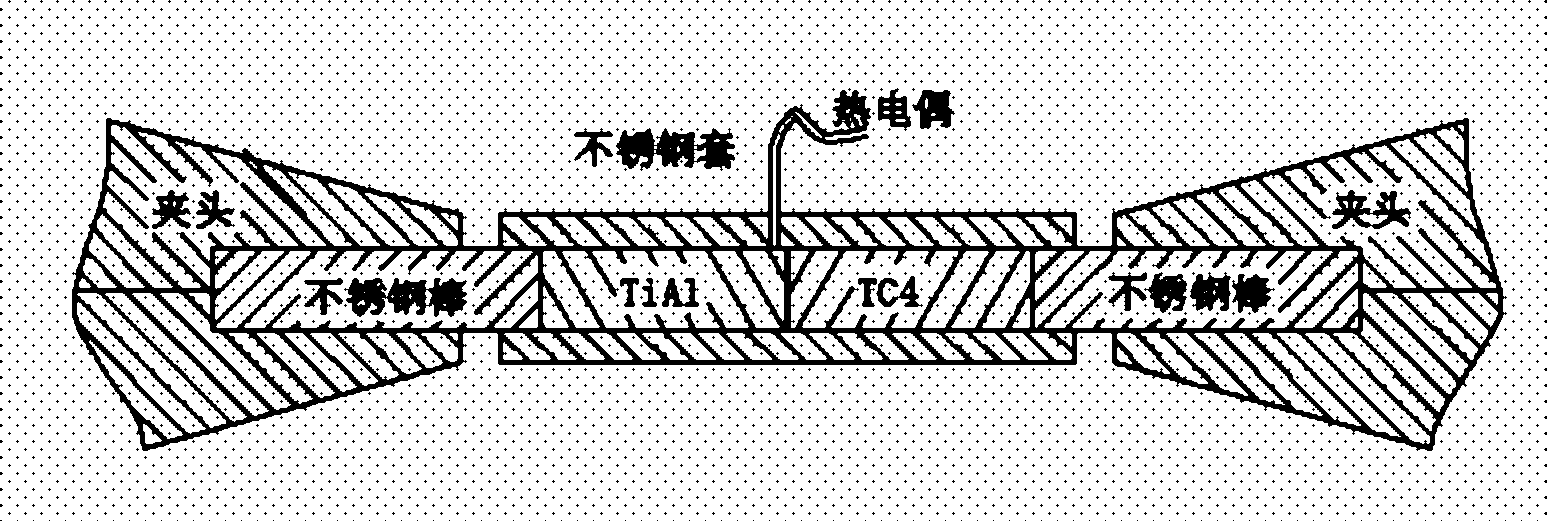

[0032] The method for carrying out diffusion welding of titanium-aluminum base alloy and titanium alloy (TC4) after laser melting, the steps are as follows:

[0033] (1) Clean the surface of titanium-aluminum-based alloy and titanium alloy (TC4): first use 200#, 400#, 600#, 800#, 1000# metallographic sandpaper to polish step by step, and then put the base metal into acetone solution Clean with ultrasound.

[0034] (2) Coating the surface of titanium-aluminum-based alloy and titanium alloy (TC4).

[0035] (3) Place the test piece to be welded in a heat treatment furnace and preheat it to 300°C.

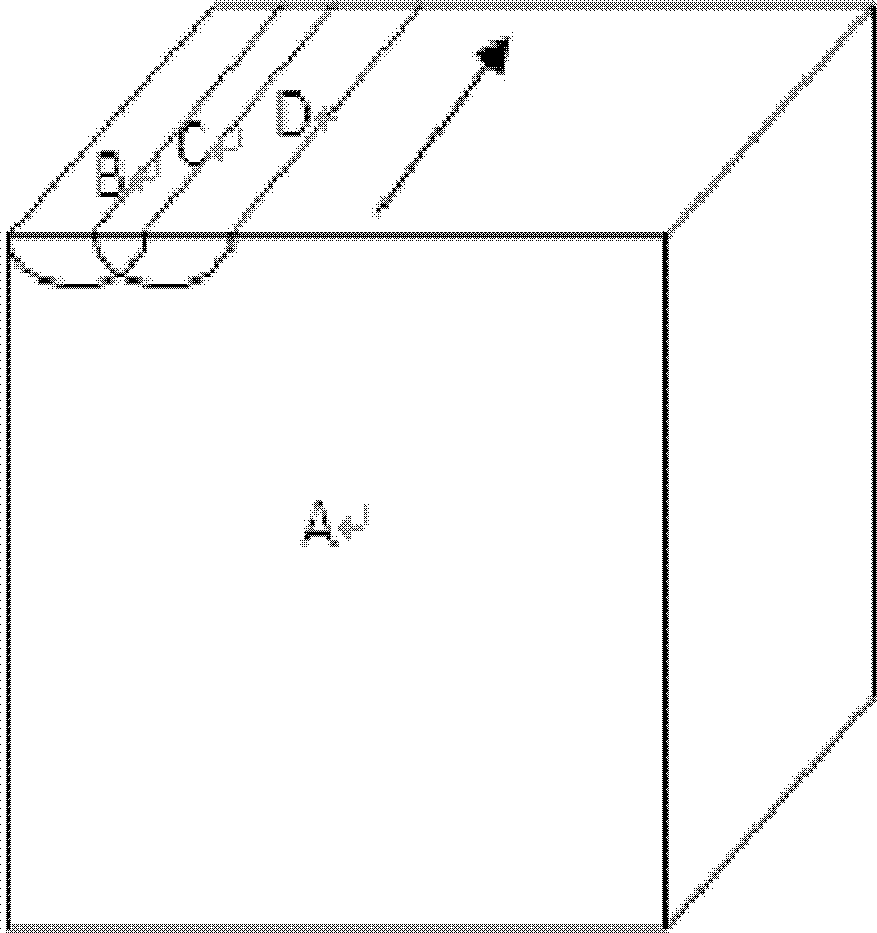

[0036] (4) The titanium-aluminum-based alloy to be welded is subjected to laser melting treatment, and the process parameters are: power 1.2KW, scanning speed 2mm / s.

[0037] (5) The titanium alloy to be welded (TC4) is subjected to laser melting treatment, the process parameters are power 1.2KW, and scanning speed 3mm / s.

[0038] (6) Put the specimen to be welded after laser meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com