Special disk spring gasket and clutch release bearing assembly

A disc spring and washer technology, which is applied in the field of clutch release bearing components, can solve the problems of lack of elastic deformation, plastic deformation of elastic washer, and excessive elastic force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The special disc spring washer and clutch release bearing assembly of the present invention will be further described below in conjunction with the accompanying drawings.

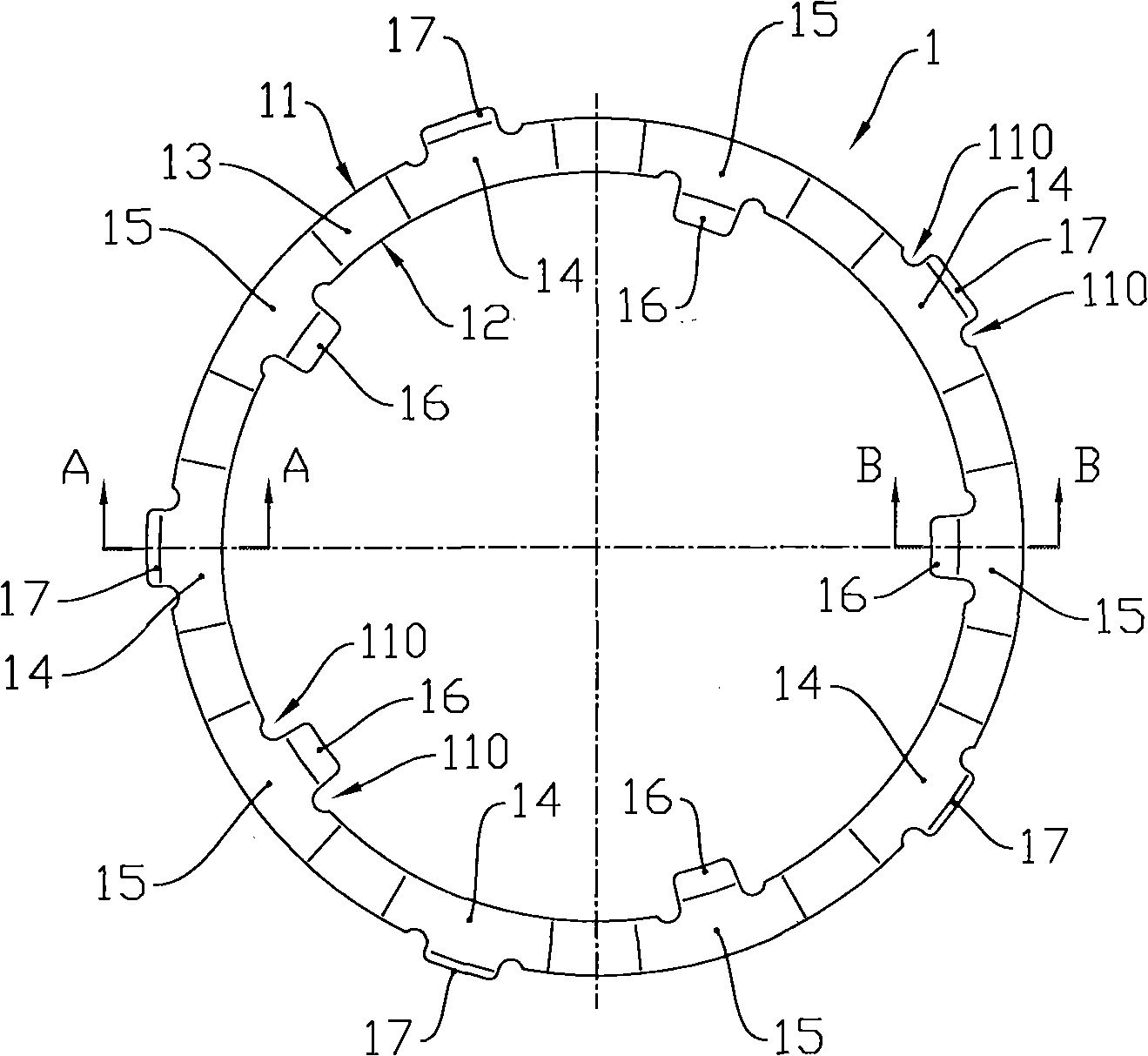

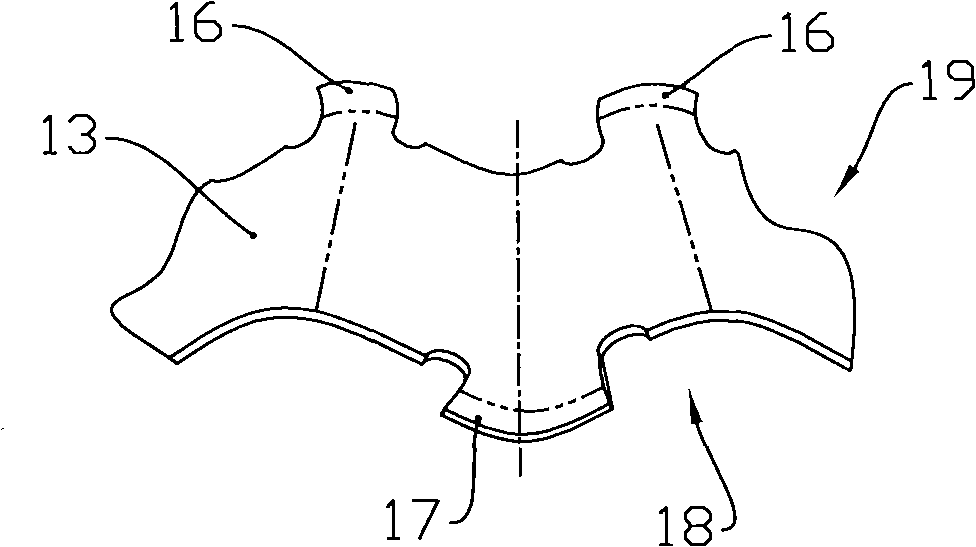

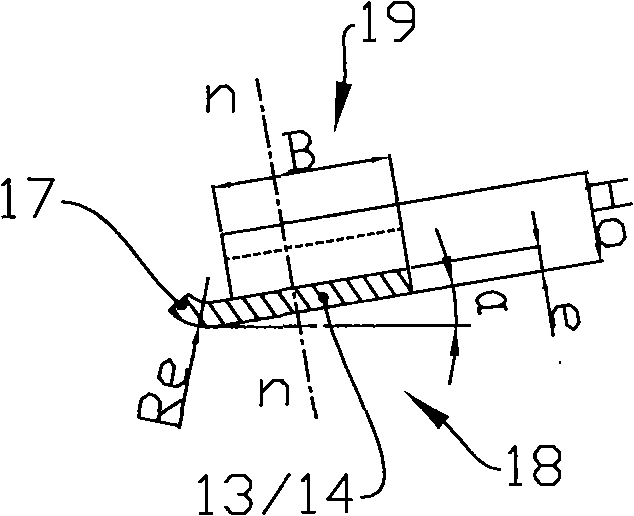

[0051] Such as Figure 1(a) , 1(b) , 1(c) and 1(d) show a schematic diagram of a preferred embodiment of the special disc spring washer of the present invention, which includes an outer edge 11, an inner edge 12, and a taper formed between the radial surface An annular corrugated body 13 with an angle α, on which a plurality of crests 15 extending from the inner edge 12 to the outer edge 11 and troughs 14 located between two adjacent crests are formed on the annular corrugated body 13, And the inner edge radula 16 protruding from the inner edge 12 extends inwardly from the crest portion 15 , and the outer edge radula 17 protrudes from the outer edge 11 extends outward from the wave valley portion 14 . Thus, the special disk spring washer of the present invention is made into a shape with a taper an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com