Experimental device of split hopkinson pressure bar based on electromagnetic force load

A technology of Hopkinson pressure bar and experimental device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problems of inability to realize low strain rate experiments, difficult control of incident wave amplitude, and limited strain range. Achieve precise control, simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

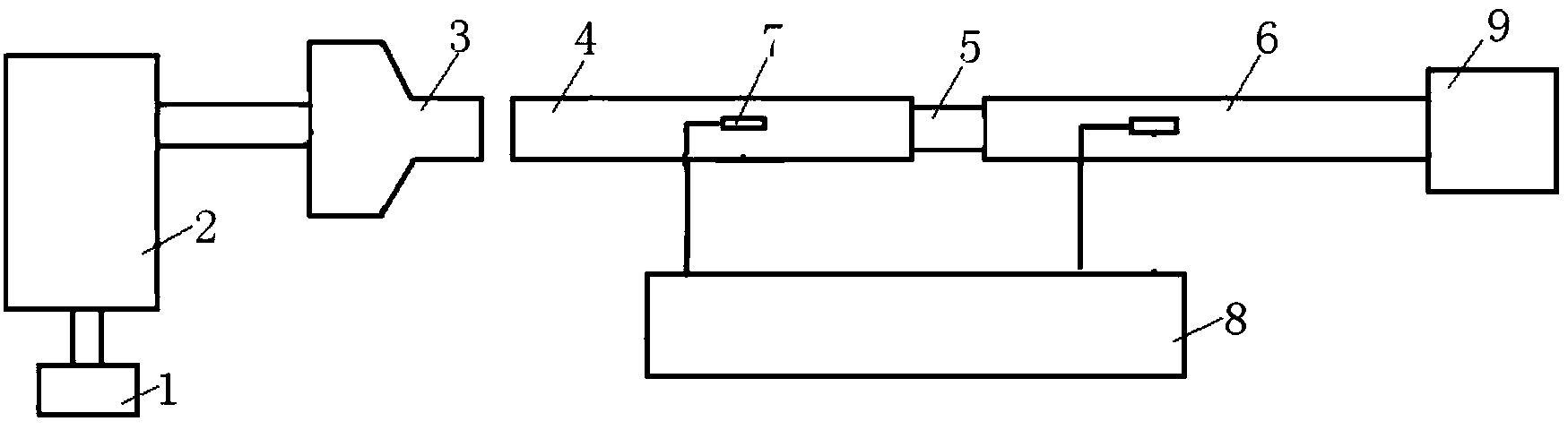

[0022] As shown in the figure, this embodiment includes an electromagnetic riveting device and a separate Hopkinson pressure bar experimental device. The electromagnetic riveting gun 3 of the electromagnetic riveting device is located at one end of the incident rod 4 of the separated Hopkinson pressure bar experimental device, and The spring between the secondary coil and the primary coil is removed, so that the secondary coil and the primary coil are naturally fitted to ensure that there is no prestress in the incident rod before the stress wave is generated. The small end of the tapered head of the electromagnetic riveting gun 3 on the electromagnetic riveting device is fully contacted with the incident end face of the incident rod 4 , and the electromagnetic riveting gun 3 is coaxial with the incident rod 4 .

[0023] The electromagnetic riveting device 2 adopts the low-voltage electromagnetic riveting device disclosed in the utility model patent publication number CN2865927...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com