Discharge lamp, and method for the production of such a discharge lamp

A discharge lamp and lamp holder technology, applied in the manufacture of discharge tubes/lamps, discharge lamps, electrode systems, etc., can solve problems such as deformation of welding points and fixed connection plates, and achieve reduction of plastic deformation, simple bending resistance- and torsional stiffness, mechanical stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

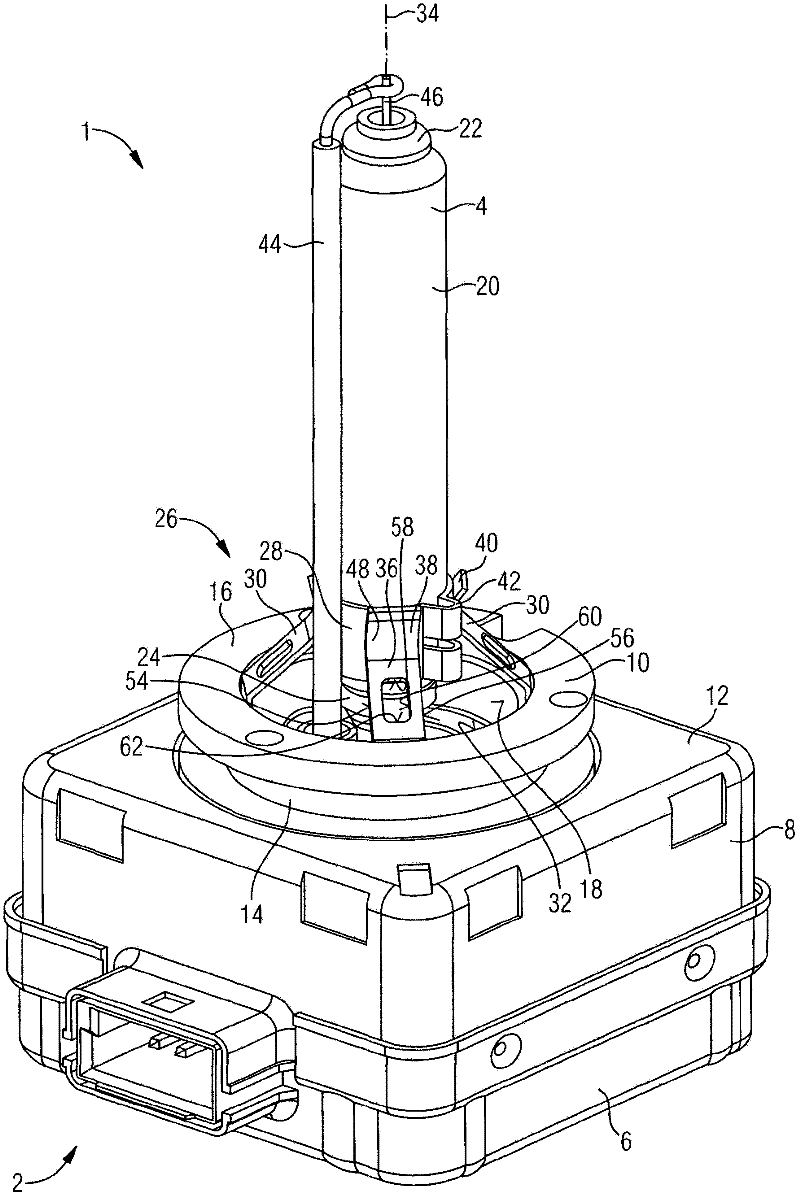

[0030] in figure 2 A perspective view of the discharge lamp 1 according to the first embodiment is shown in. This refers to a high-pressure discharge lamp that can be used as a D-lamp in vehicle lighting, especially as a D1-, D2-, D3-, or D4-lamp. The discharge lamp 1 has a lamp vessel 4 made of quartz glass, which is fixed by a multi-part metal socket 2 and has electrodes arranged therein for causing a gas discharge. The lamp holder 2 is basically constructed in a square shape, with an upper part of the holder and a lower part 6, 8 of the holder. A substantially cylindrical socket element 10 is installed in the top surface 12 of the upper part 8 of the lamp holder, and the lamp housing 4 is fixed by the element. The socket element 10 has an annular connecting piece 14 extending away from the top surface 12, and the retaining ring 16 is designed on the connecting piece as a component of a bayonet connection for fixing the discharge lamp 1 in a vehicle lighting lamp, for examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com