Adjusting and controlling method for orientation of precipitation phase in magnesium alloy

A magnesium alloy and precipitation technology, which is applied in the field of adjusting the orientation of the precipitation in the magnesium alloy, can solve the problems of poor aging hardening effect, small hindrance to the movement of basal plane dislocation, and difficulty in controlling the orientation of the precipitation in the magnesium alloy. The effect of chemical pinning, reducing production cost, and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

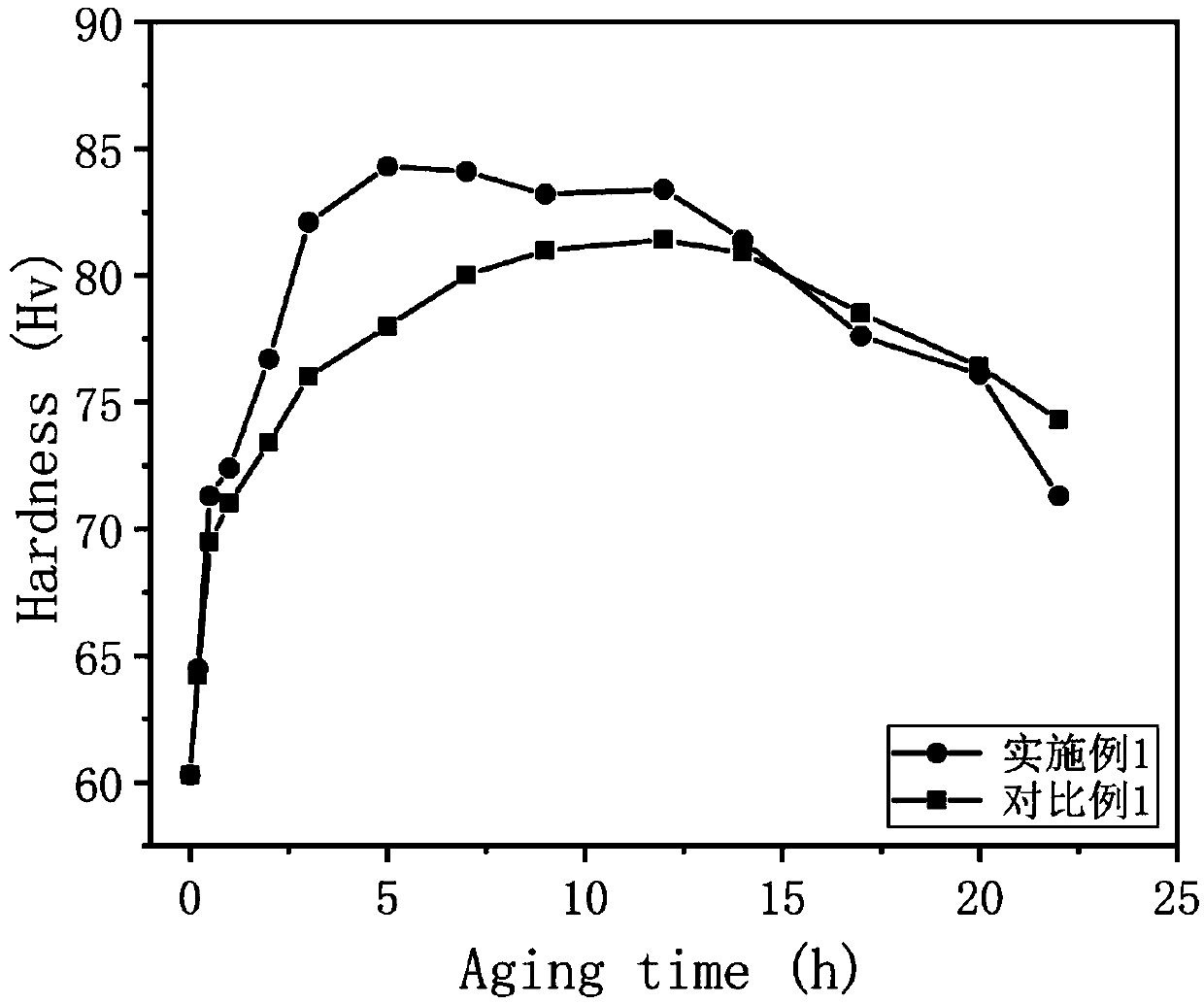

Embodiment 1

[0029] A method for regulating the orientation of precipitated phases in a magnesium alloy, comprising the following steps:

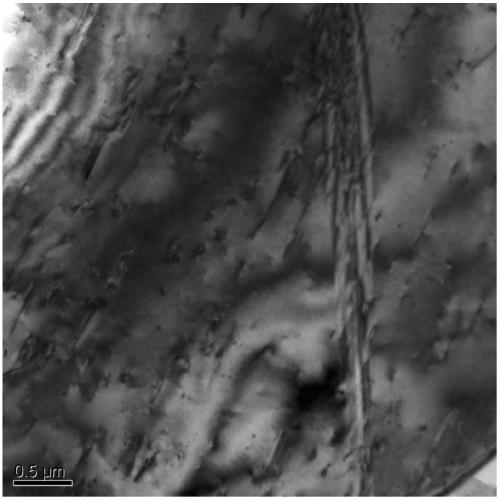

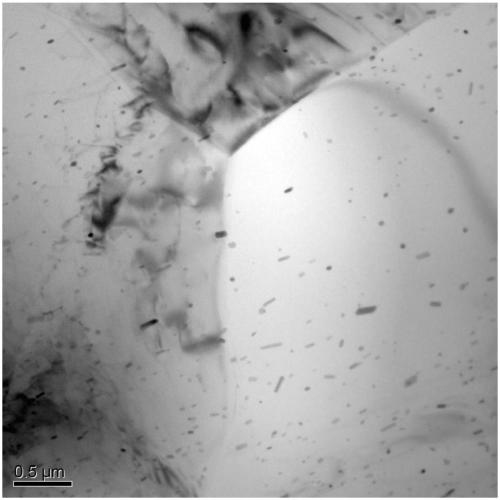

[0030] A. The magnesium alloy ingot whose composition is Mg-6Zn (wt%) and whose size is Φ85×10mm is solid solution treated, and the magnesium alloy ingot after the solution treatment is cooled to room temperature to remove the head and tail of the wagon to remove the surface of the magnesium alloy ingot The oxide layer ensures that the magnesium alloy ingot is pure and free of impurities. The magnesium alloy ingot after solution treatment is hot extruded into extruded rods, wherein the solution treatment temperature is 420°C, the solution time is 20h, and the hot extrusion temperature of the magnesium alloy ingot after solution treatment is 300°C , before extrusion, keep the extrusion temperature for 40 minutes. After the insulation, the magnesium alloy ingot is hot-extruded at the speed of 2.5cm / s in the extruder, and the diameter of the extruded rod i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com