Stabilization technology for 5383 aluminum alloy

A stabilized, aluminum alloy technology, applied in the field of aluminum alloys, can solve problems such as corrosion failure, achieve stable performance, simple preparation process, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A stabilization process of 5383 aluminum alloy includes the following steps:

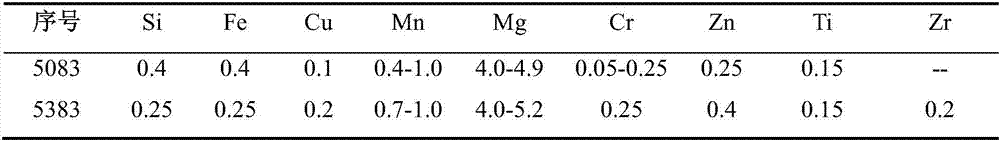

[0024] A. Produce 5383 aluminum alloy ingots by semi-continuous water-cooling casting method. The mass percentage ratio of each element of the aluminum alloy ingots is: Si 0.25%, Mg 5.2%, Fe 0.25%, Cu 0.2%, Mn 1.0%, Cr 0.25% , Ti 0.15%, Zn0.4%, Zr 0.2%, the balance Al.

[0025] B. The aluminum alloy ingot is milled and then hot rolled to obtain an aluminum alloy plate, wherein the thickness of the aluminum alloy plate after hot rolling is 6.0 mm, and the hot rolling temperature is 340°C.

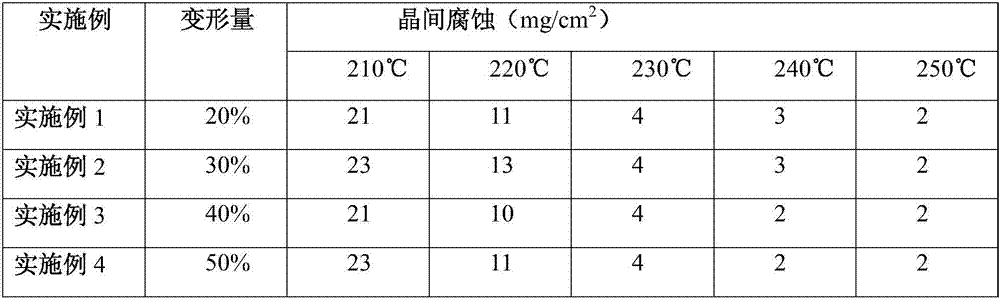

[0026] C. Cold-roll the hot-rolled aluminum alloy sheet, the thickness of the cold-rolled aluminum alloy sheet is 4.8mm, and the cold-rolling deformation is 20%, and then the cold-rolled aluminum alloy sheet is heated at 210°C, 220°C , 230℃, 240℃, 250℃ for 2 hours of stabilization annealing.

[0027] D. Sawing the stabilized annealed aluminum alloy sheet on a sawing machine according to the specified size.

Embodiment 2

[0029] The difference between Example 2 and Example 1 is that the thickness of the aluminum alloy sheet after cold rolling in step C is 4.2 mm, and the cold rolling deformation is 30%.

Embodiment 3

[0031] The difference between Example 3 and Example 1 is that the thickness of the aluminum alloy sheet after cold rolling in step C is 3.6 mm, and the cold rolling deformation is 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com