Method for producing ultra-low-temperature high-core-impact-value acid-resistant container steel by using casting blank

A technology of ultra-low temperature and impact value, applied in the field of steel, can solve the problems of poor HIC resistance, unstable low-temperature impact performance of acid-resistant container steel, unstable weldability, etc., achieve simple production process, improve HIC resistance, and eliminate segregation Bring the effect

Active Publication Date: 2019-12-13

NANJING IRON & STEEL CO LTD

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method successfully solves technical difficulties such as unstable low-temperature impact performance, poor HIC resistance, and unstable weldability of acid-resistant container steel with ultra-low temperature and high core impact value in the production of slabs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

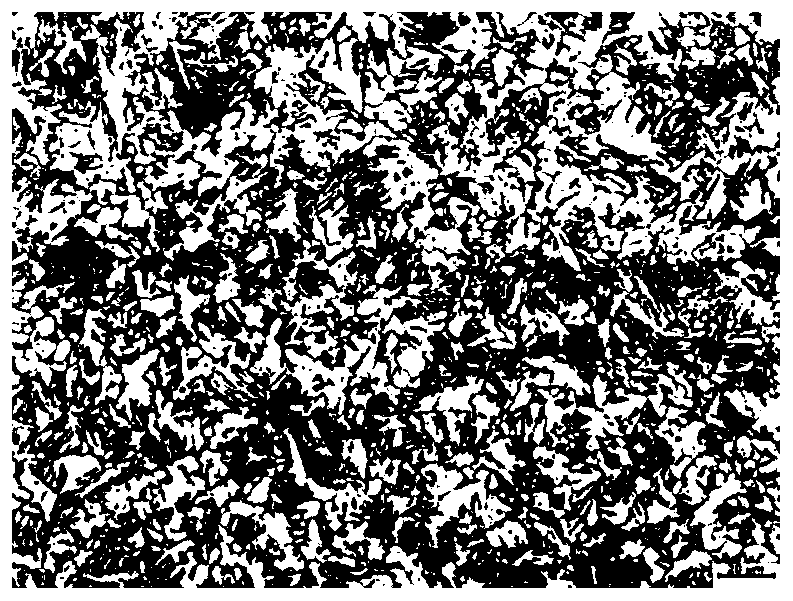

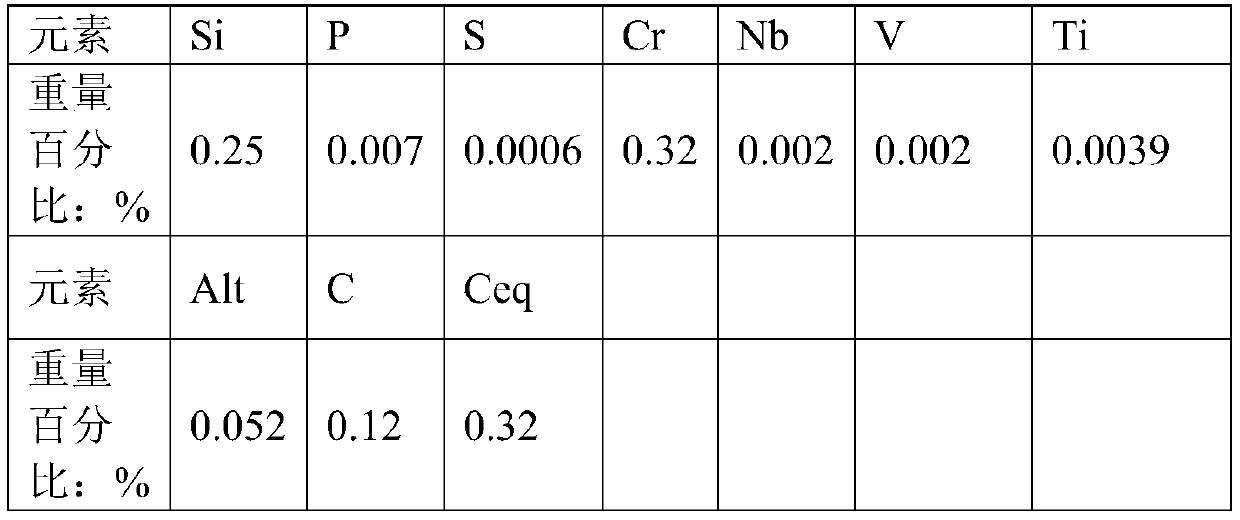

[0033] The actual weight percentage of the chemical composition of ultra-low temperature high core impact value acid-resistant container steel produced by cast slab

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for producing an ultra-low-temperature high-core-impact-value acid-resistant container steel by using a casting blank. The method comprises the following steps of determining the steelmaking components; carrying out a heating process; carrying out a tapping and rolling process; and carrying out a heat treatment process. According to the method, the ultra-low-temperature high-core-impact-value acid-resistant container steel is produced through the design of being low in carbon and small in chromium alloy component amount in combination with the reasonable rolling control and cooling control, quenching and tempering and heat treatment processes, so that the mechanical property reaches the technical standard requirements, and the acid resistance meets the requirements of NACE-TM2084-2016, the actual level of the mechanical property reaches the following standards that the yield strength is greater than or equal to 340 MPa, the tensile strength is greater than or equal to 480 MPa, the elongation is greater than or equal to 35%, the transverse Akv at the core of a steel plate and at 60 DEG C below zero is greater than or equal to 240 J, the HIC resistance reaches the standards that CLR is equal to 0%, CTR is equal to 0%, and the CSR is equal to 0%, and therefore, the problems of unstable low-temperature impact property, poor HIC resistance, unstableweldability and the like of the production of the ultra-low-temperature high-core-impact-value by using a casting blank in the prior art are solved.

Description

technical field [0001] The invention belongs to the technical field of iron and steel, and in particular relates to a method for producing ultra-low temperature and high core impact value acid-resistant container steel from casting slabs. Background technique [0002] According to the requirements of green, environmental protection and clean energy, the petrochemical and coal chemical industries have developed rapidly. However, sulfur-containing oil and gas have higher and higher requirements for the resistance to hydrogen-induced cracking of container steels used in wet H2S environment, and the corrosion and hydrogen-induced cracking accidents of low-temperature pressure vessels and pipelines caused by wet H2S environment are constantly increasing. The central segregation of hydrogen-induced cracking container steel is very difficult to control, the impurity content in the core is higher, and the inclusions such as MnS and Al2O3 are more likely to gather in the core, so its...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/24C22C38/26C22C38/28C21D1/18C21D8/02

CPCC21D1/18C21D8/0226C21D2211/002C21D2211/005C22C38/002C22C38/02C22C38/04C22C38/06C22C38/24C22C38/26C22C38/28

Inventor 郑建平张丙军方磊

Owner NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com