Patents

Literature

30results about How to "Lower upgrade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

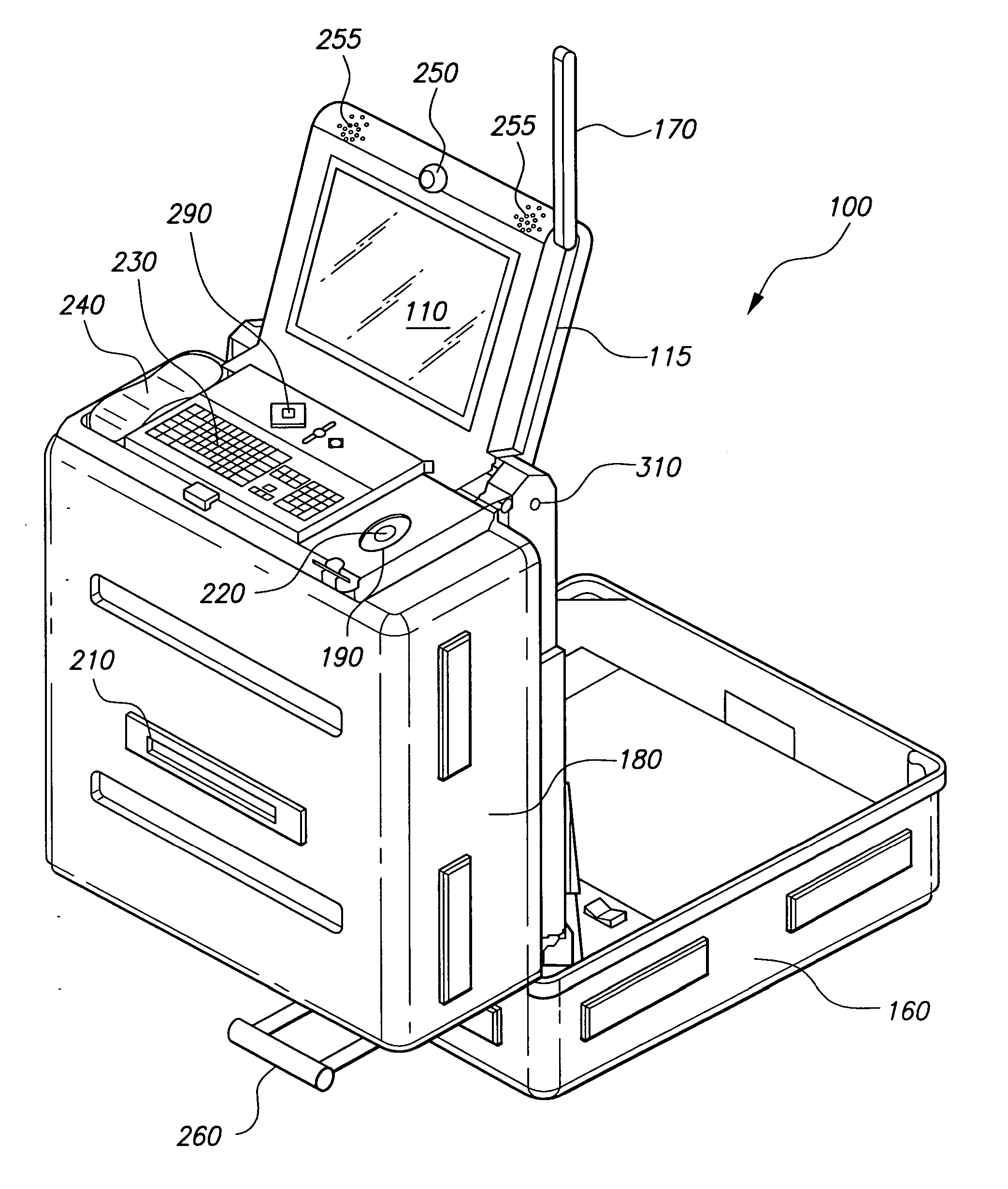

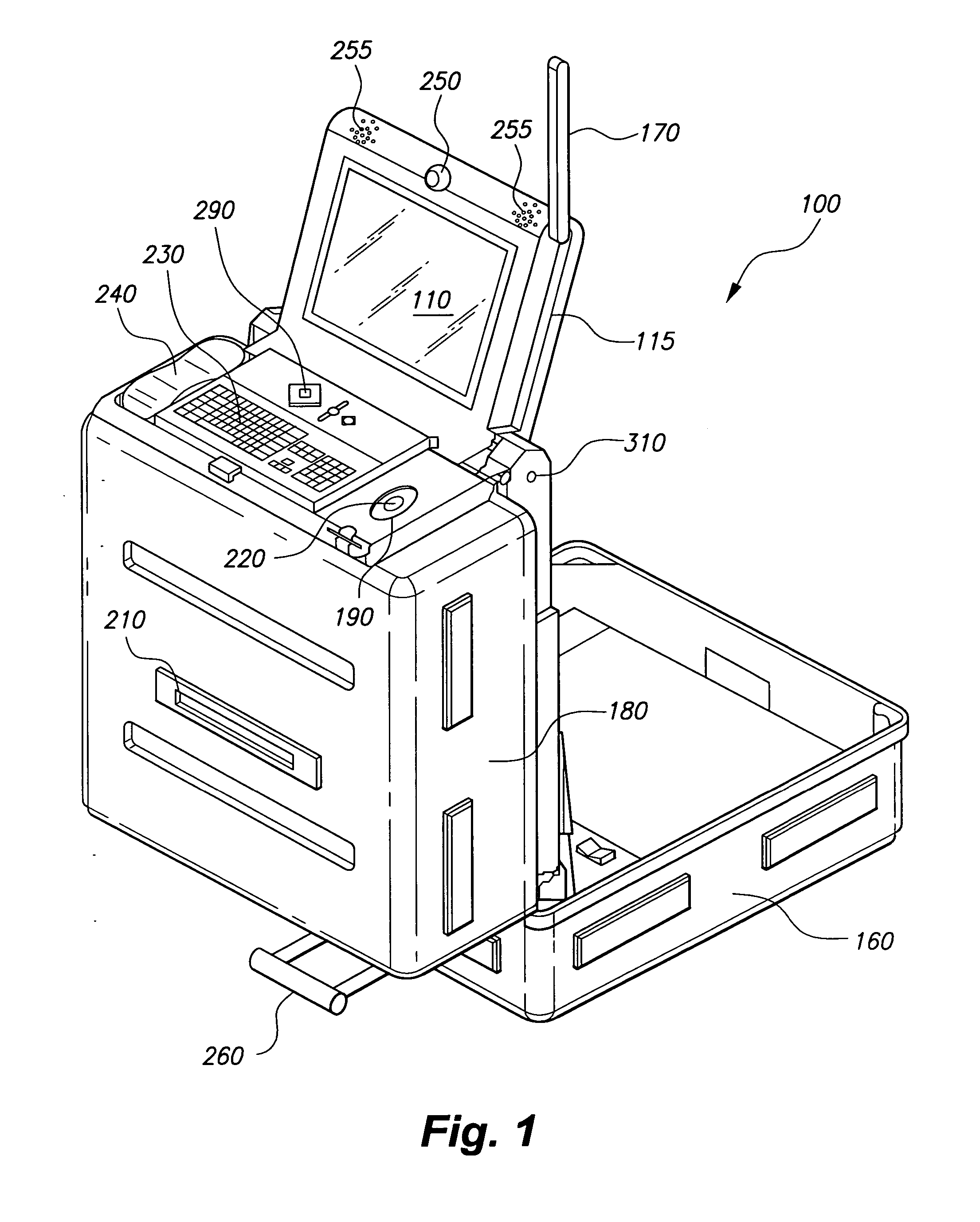

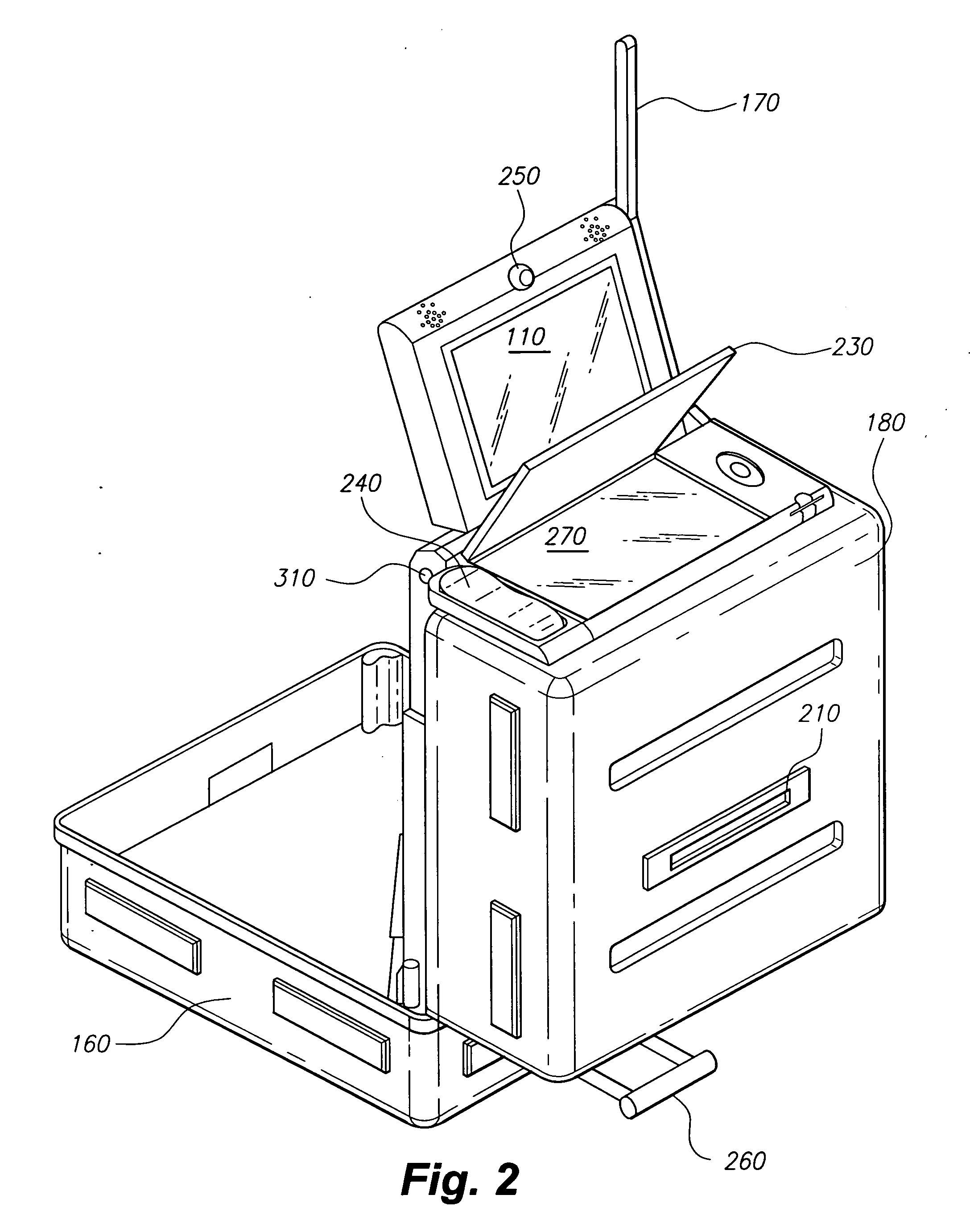

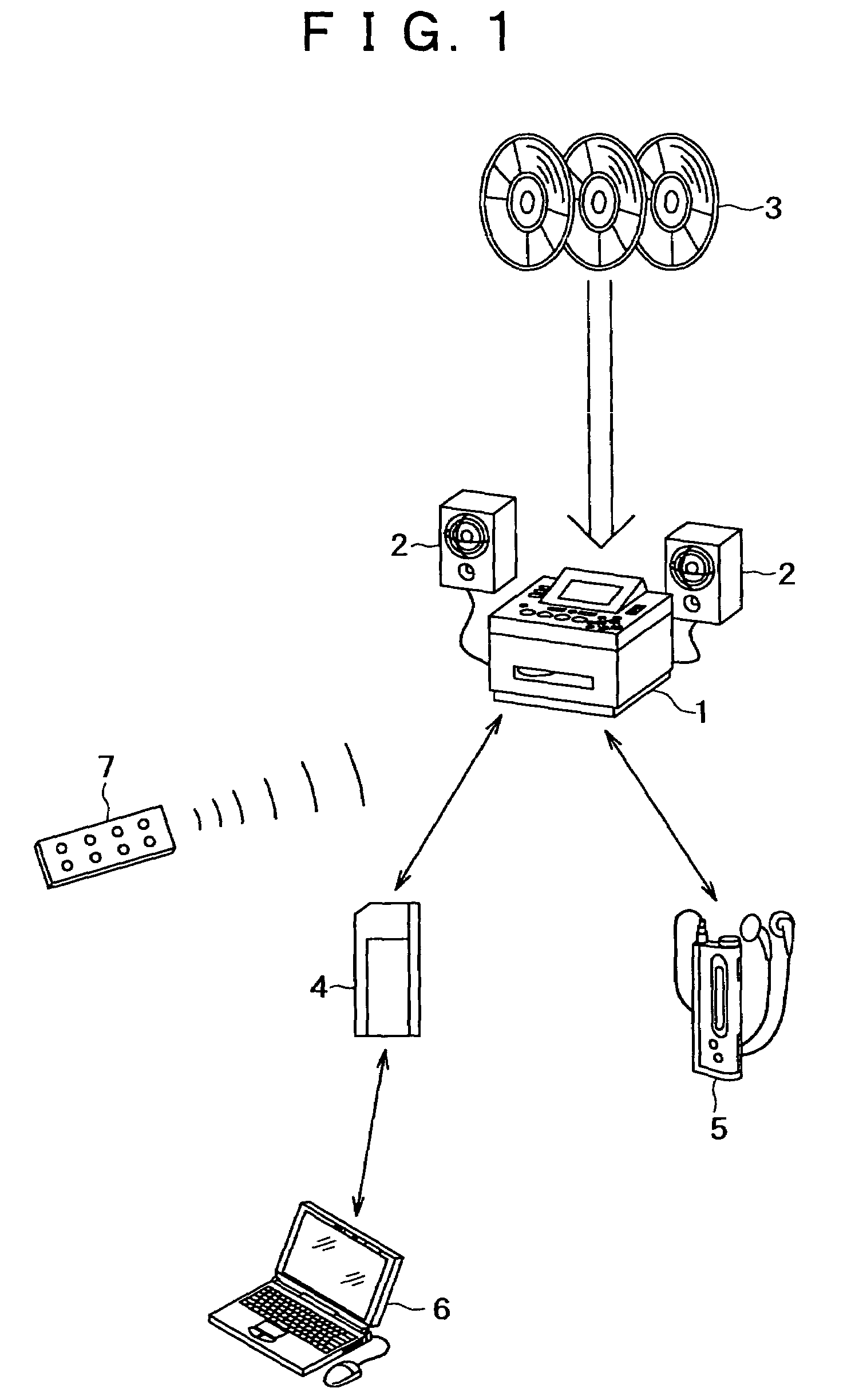

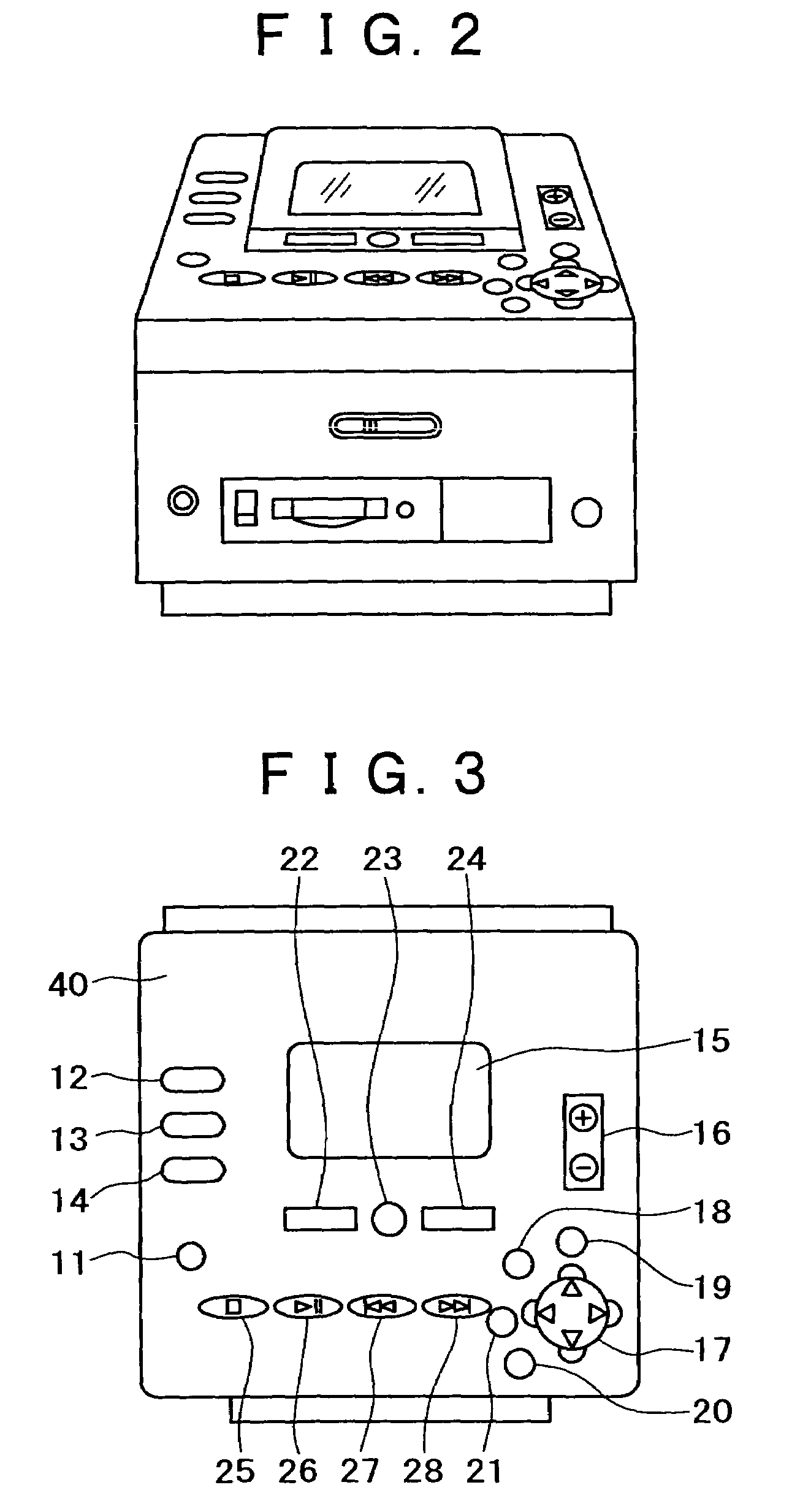

Rapid depolyment portable interactive kiosk

InactiveUS20050137942A1Easily folded awayEasy to foldCash registersCommerceElectricityInteractive kiosk

A portable information kiosk. The kiosk has a self contained power supply for a computer, a display, a digital camera, a cellular, satellite capable telephone, an antenna, a printer and a flat bed scanner, all electrically connected to each other and capable of being stored in a small carrying case. A method of deploying the kiosk does not require any attaching of parts together and can be done quickly. The kiosk is ideal for in the field communications and data acquisition, such as in disasters, emergencies, or any in the field environmental monitoring.

Owner:LAFLEUR BERNARD B

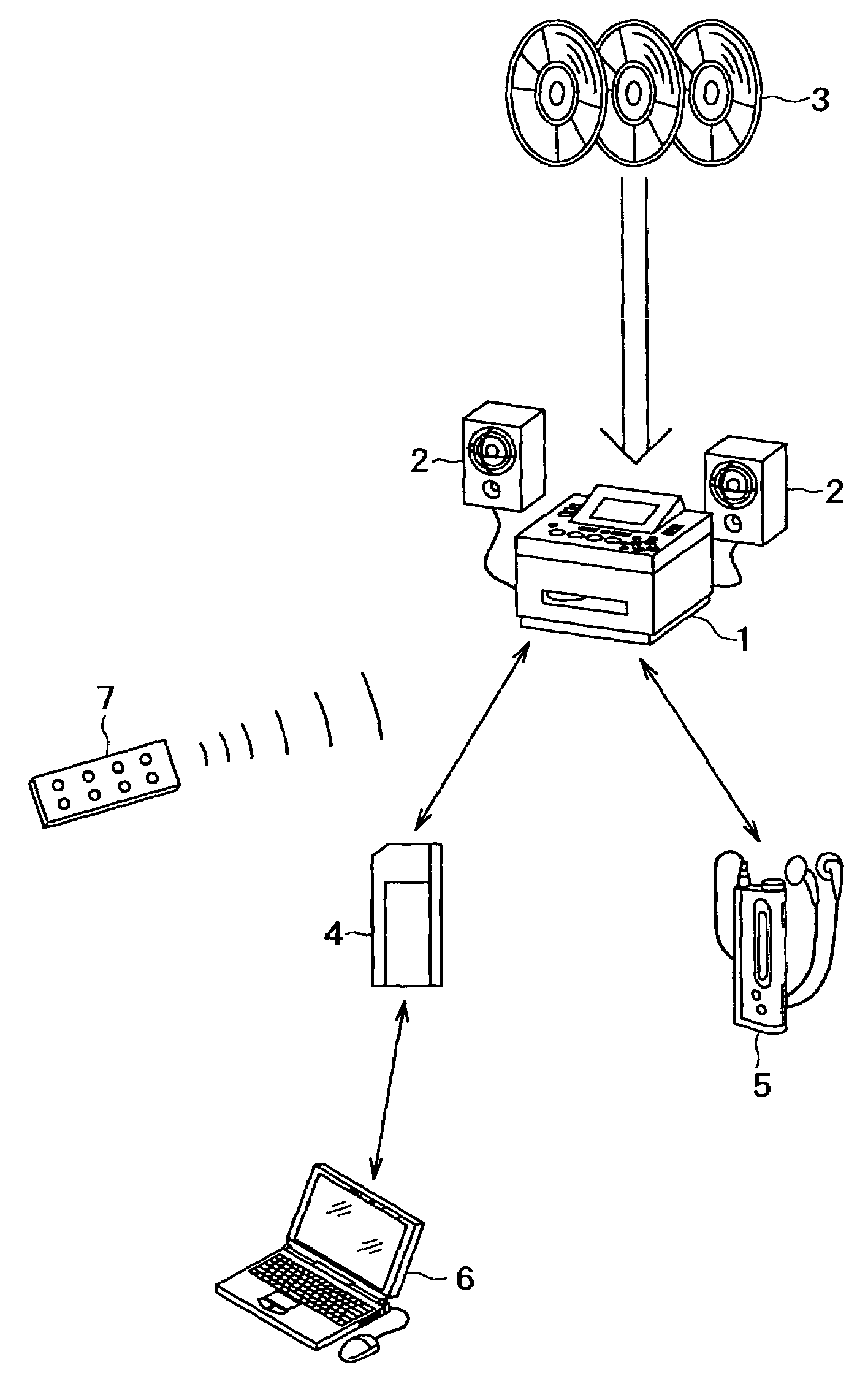

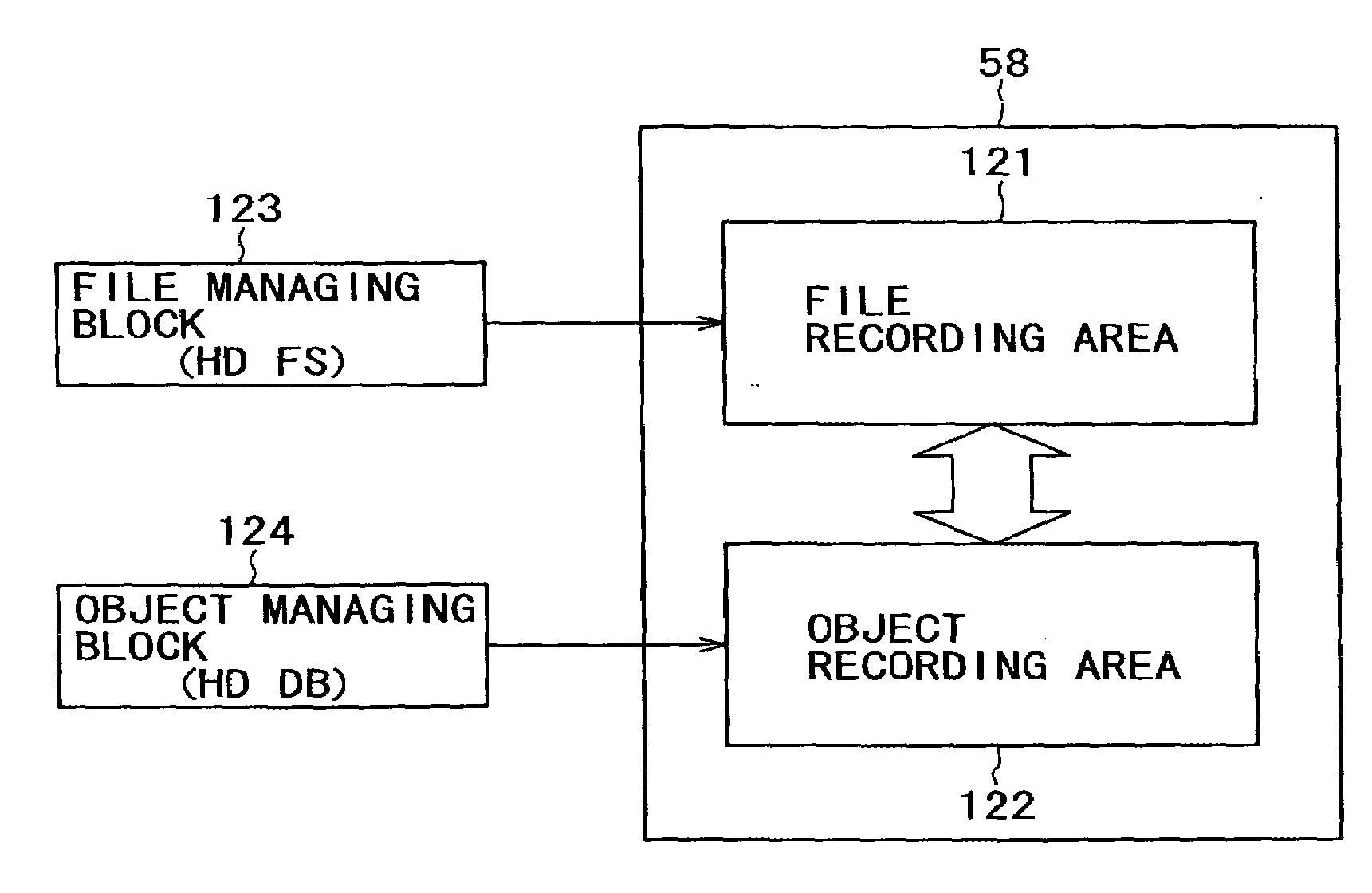

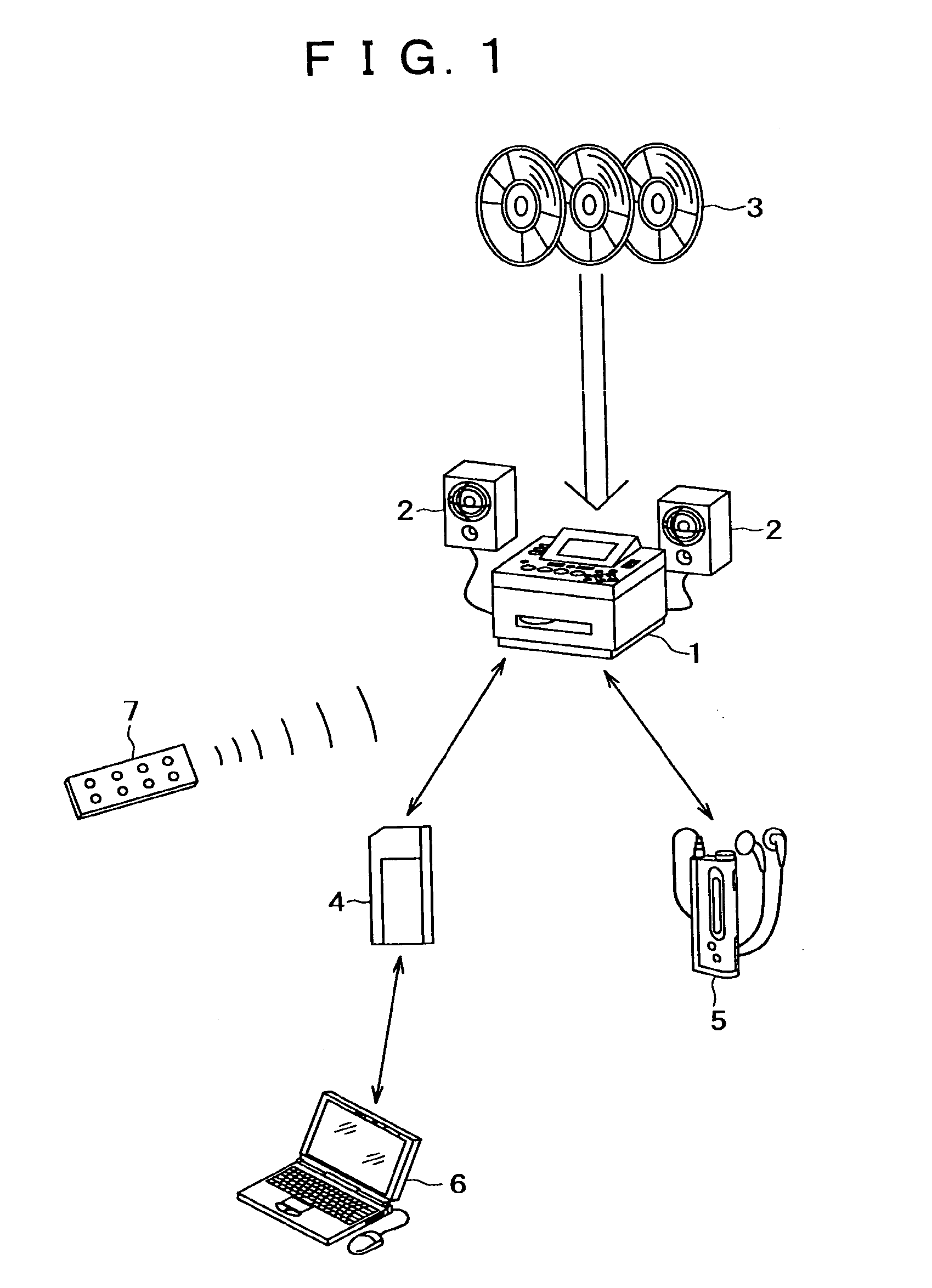

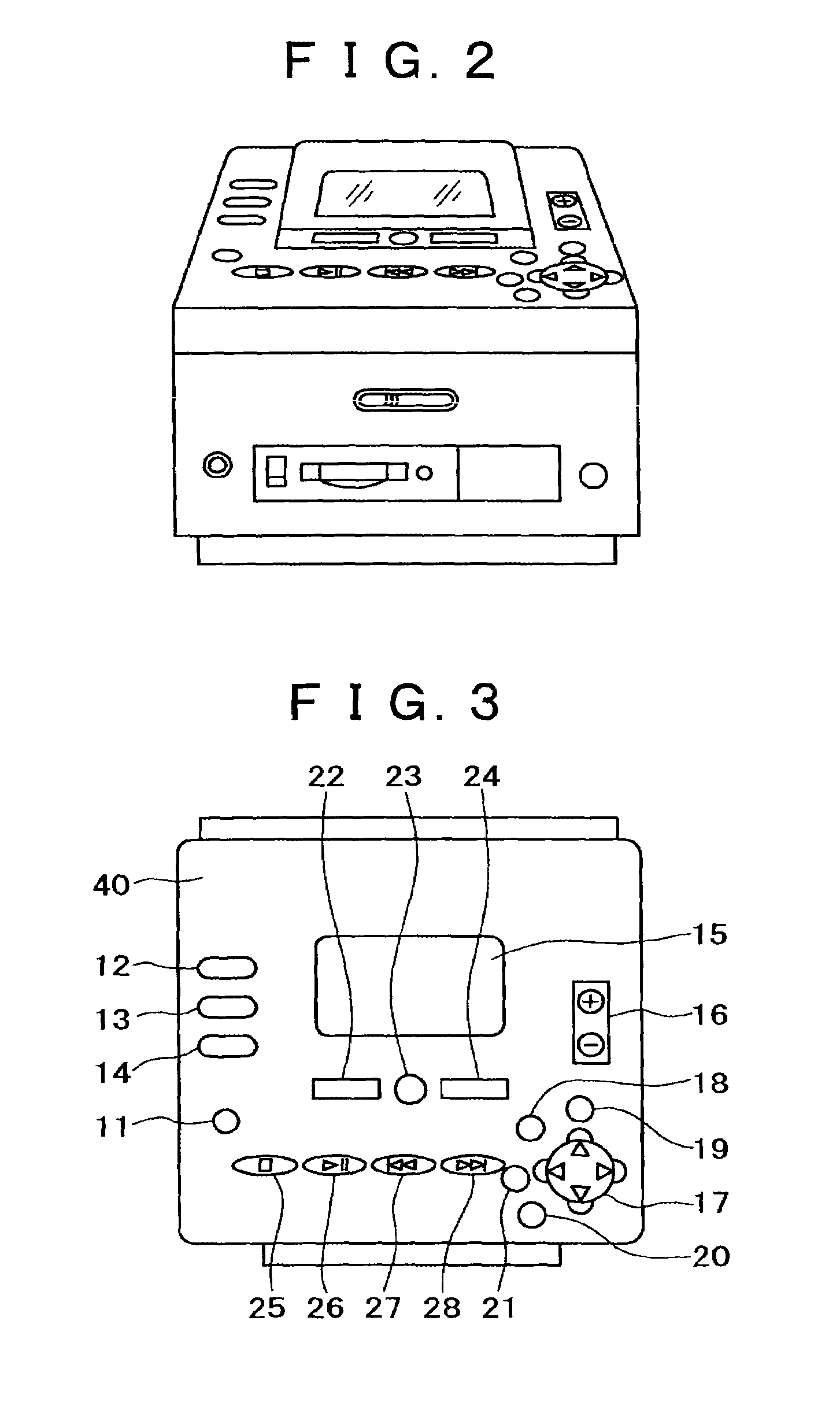

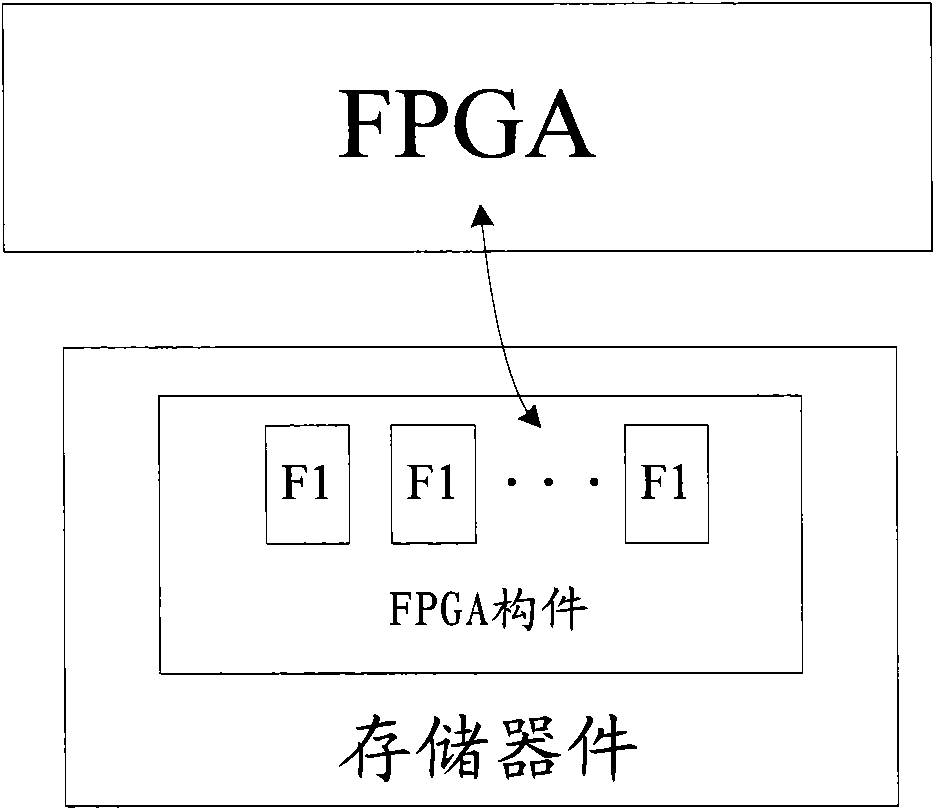

Information processing apparatus including storage

InactiveUS7600224B2Control program with easeLower upgradeProgram control using stored programsResource allocationInformation processingStorage area

The present invention relates to an information apparatus and method suitable for use in upgrading control programs readily by a user. In step S501, a storage area to store an upgraded firmware is determined. In step S502, the upgraded firmware is provided. In step 503, the provided firmware is decrypted and re-encrypted. In step S504, re-encrypted firmware is written into the storage area determined in step S501. In step S505, a maximum marker is detected. In step S506, a value obtained by adding 1 to the maximum marker provides the marker corresponding to the storage area in which the firmware was stored in step S504. The present invention is applicable to, for example, an audio data server.

Owner:SONY CORP

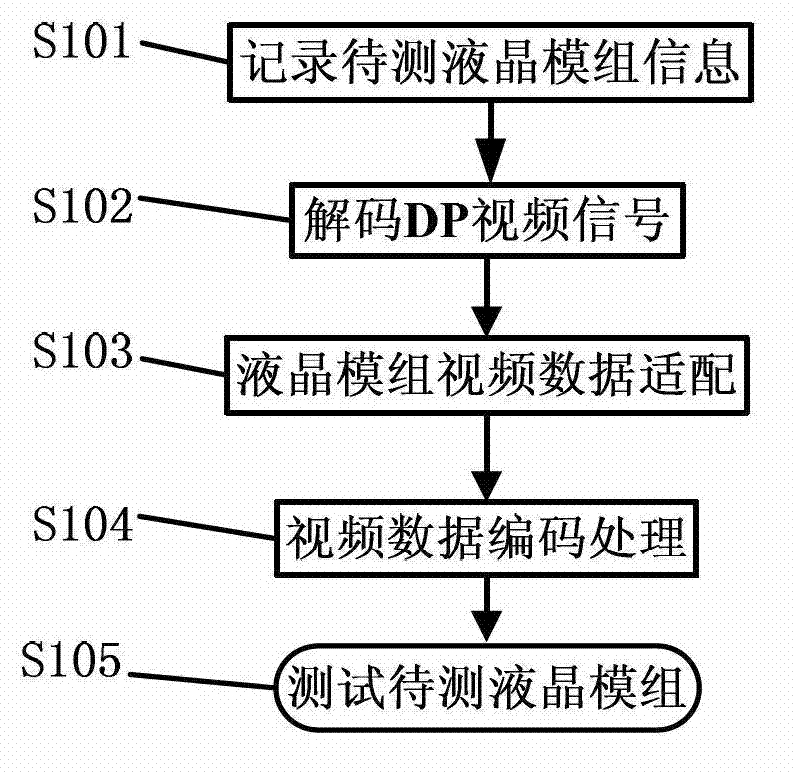

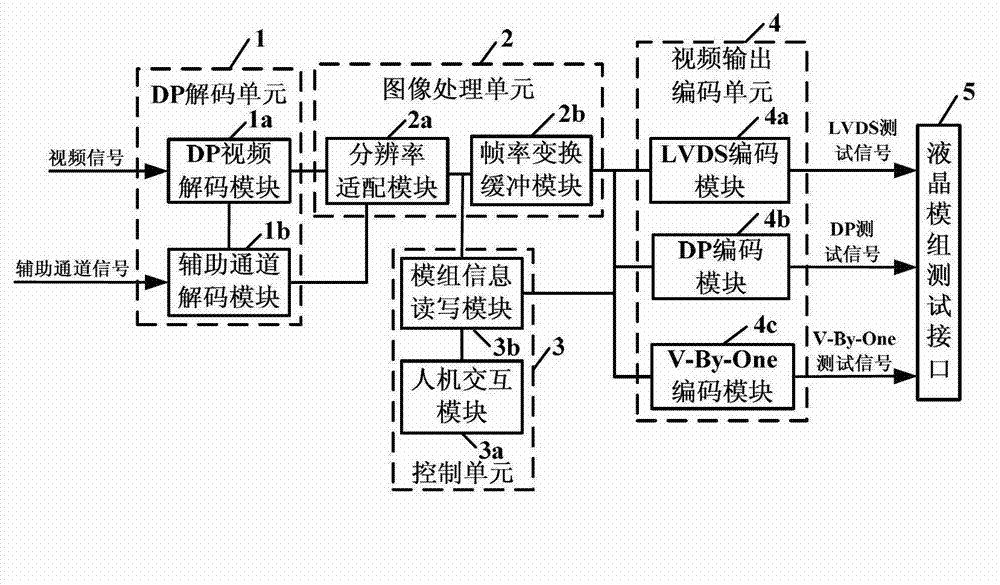

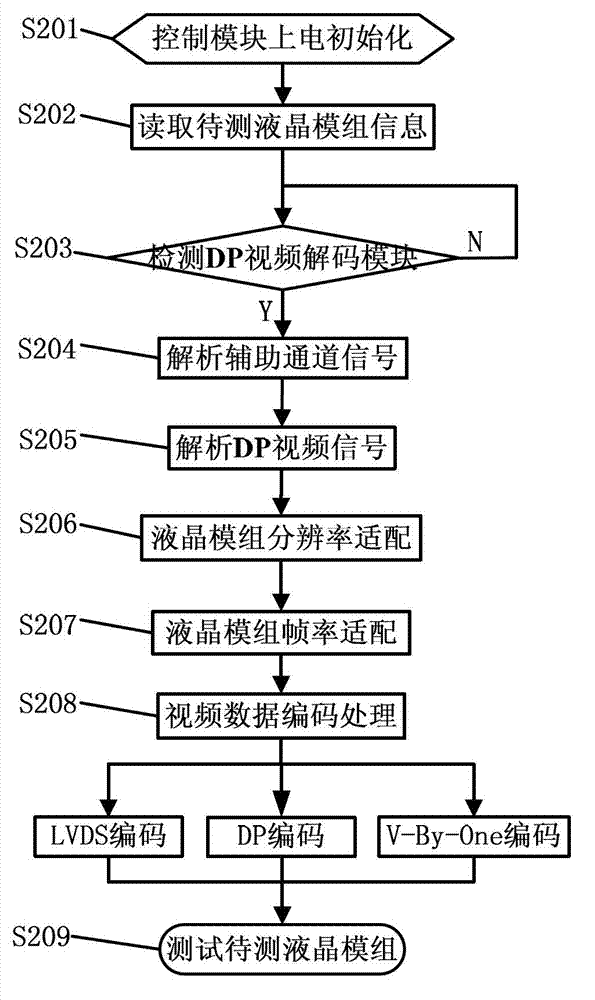

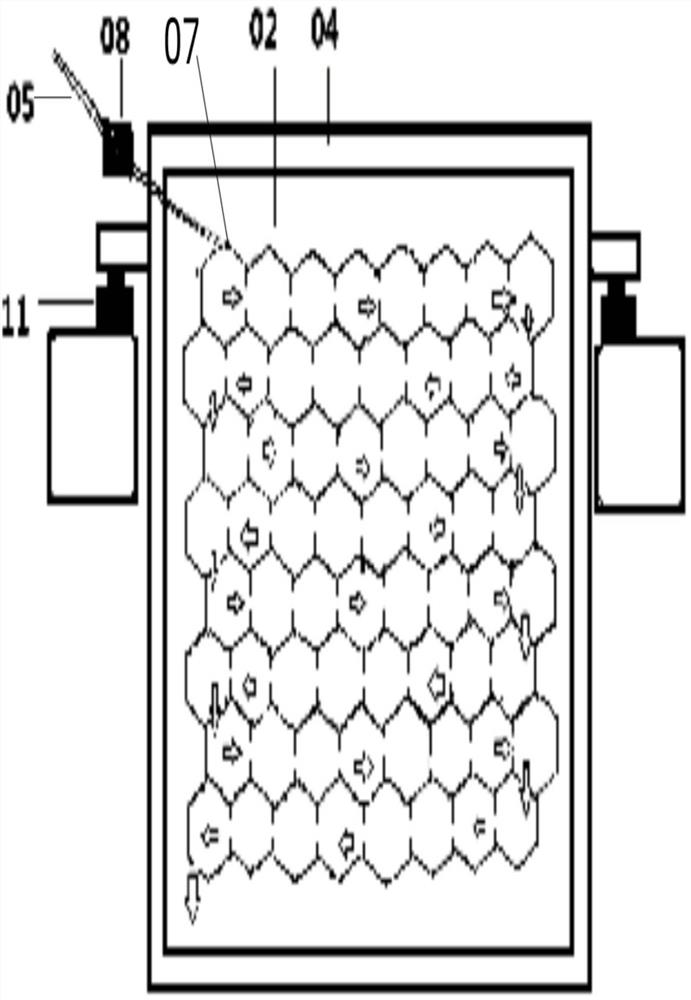

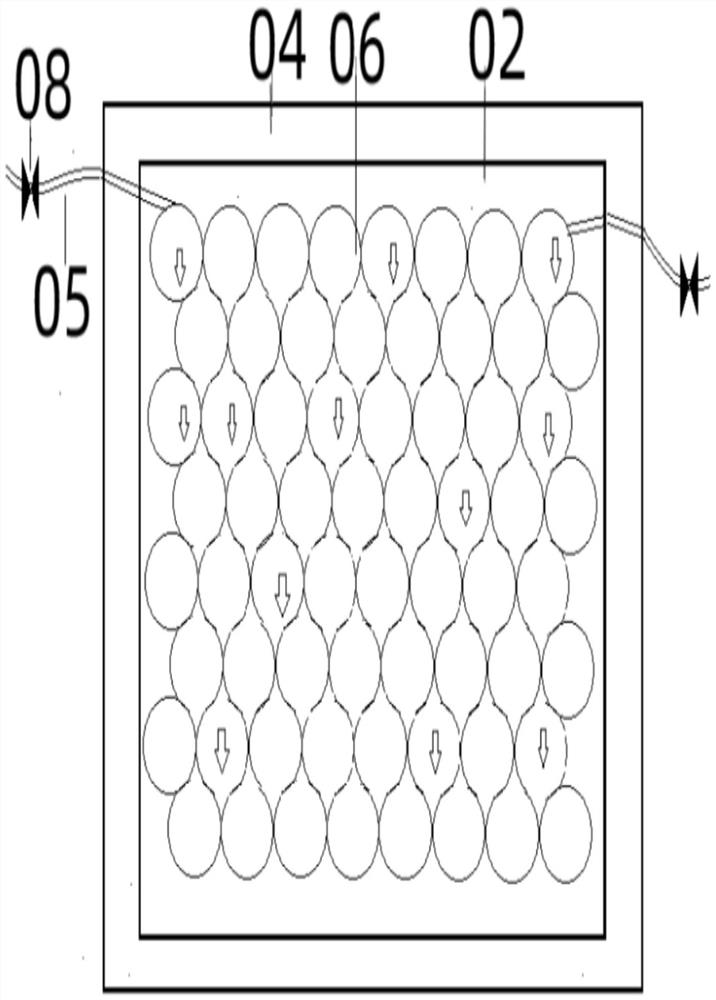

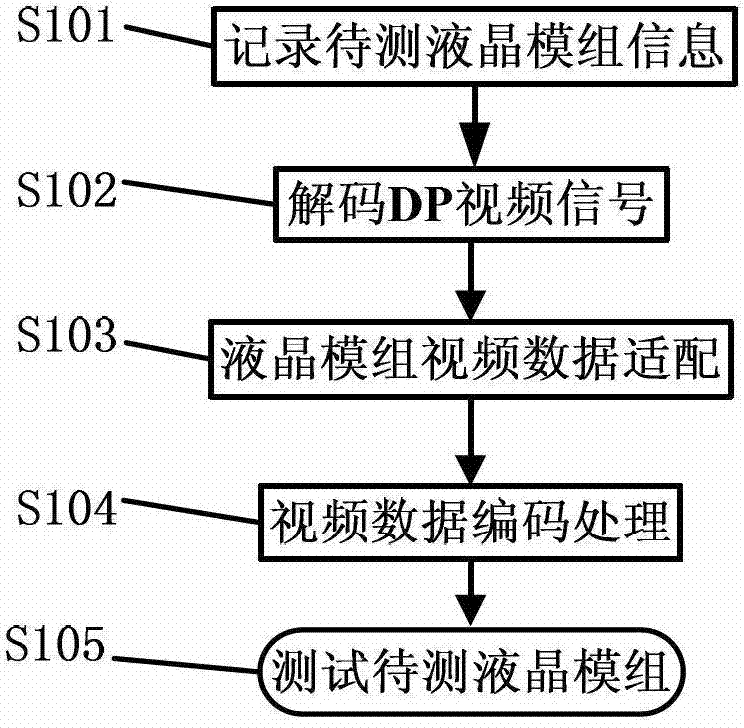

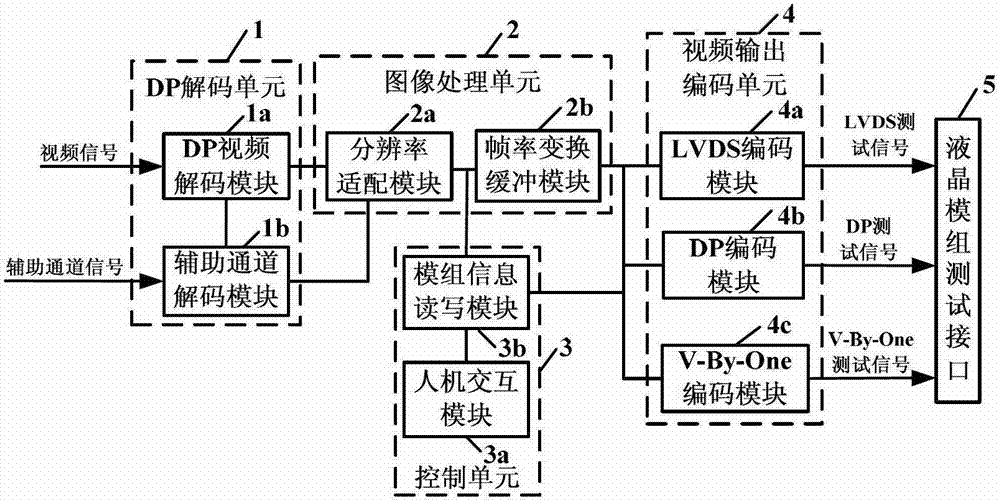

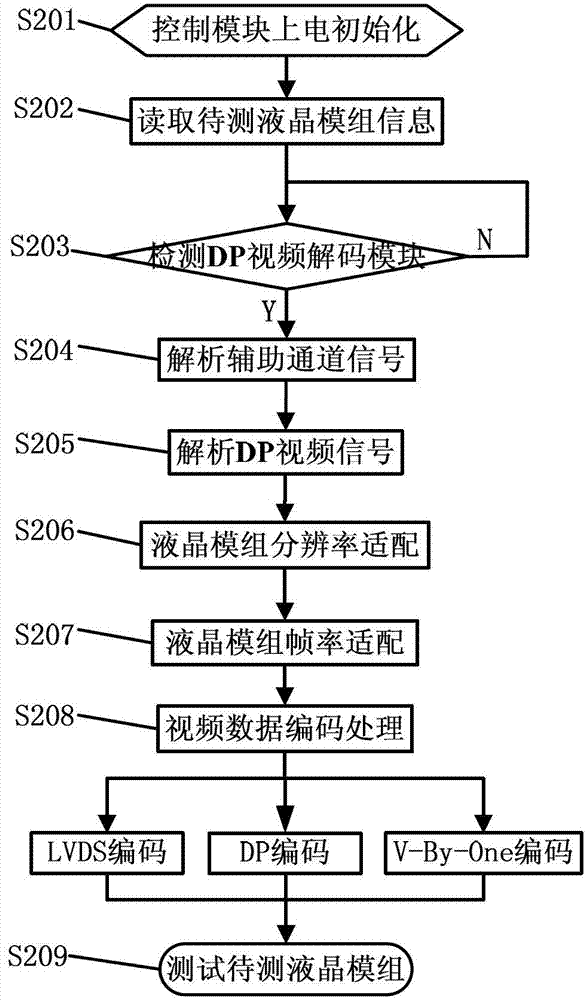

DP (Digital Processing) decoding and automatic resolution adjusting liquid crystal display module testing method and device

ActiveCN103050073AShorten adjustment timeImprove test efficiencyStatic indicating devicesCommunication interfaceTest efficiency

The invention discloses a DP (Digital Processing) decoding and automatic resolution adjusting liquid crystal display module testing method and a device, and relates to the field of liquid crystal display module testing. The testing method comprises the following steps of: decoding DP video signals to obtain video data and video parameter information thereof, wherein the video parameter information comprises resolution parameters; matching the video data with video data required by a liquid crystal display module to be tested according to the video parameter information and the video parameter information of the liquid crystal display module to the tested; conducting video encoding processing to the matched video data according to the communication interface and the video time sequence parameter of the liquid crystal display module to be tested to obtain video testing signals which are matched with the communication interface of the liquid crystal display module to be tested, and the video testing signals test the liquid crystal display module to be tested. The DP decoding and automatic resolution adjusting liquid crystal display module testing method and the device have the advantages that the energy consumption is lower during liquid crystal display module testing, the resolution can be automatically adjusted according to the liquid crystal display module, the liquid crystal display modules of different types can be automatically adapted, and not only is the testing cost lower and the testing efficiency higher, but also the energy consumption is lower and the stability and the reliability are higher.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

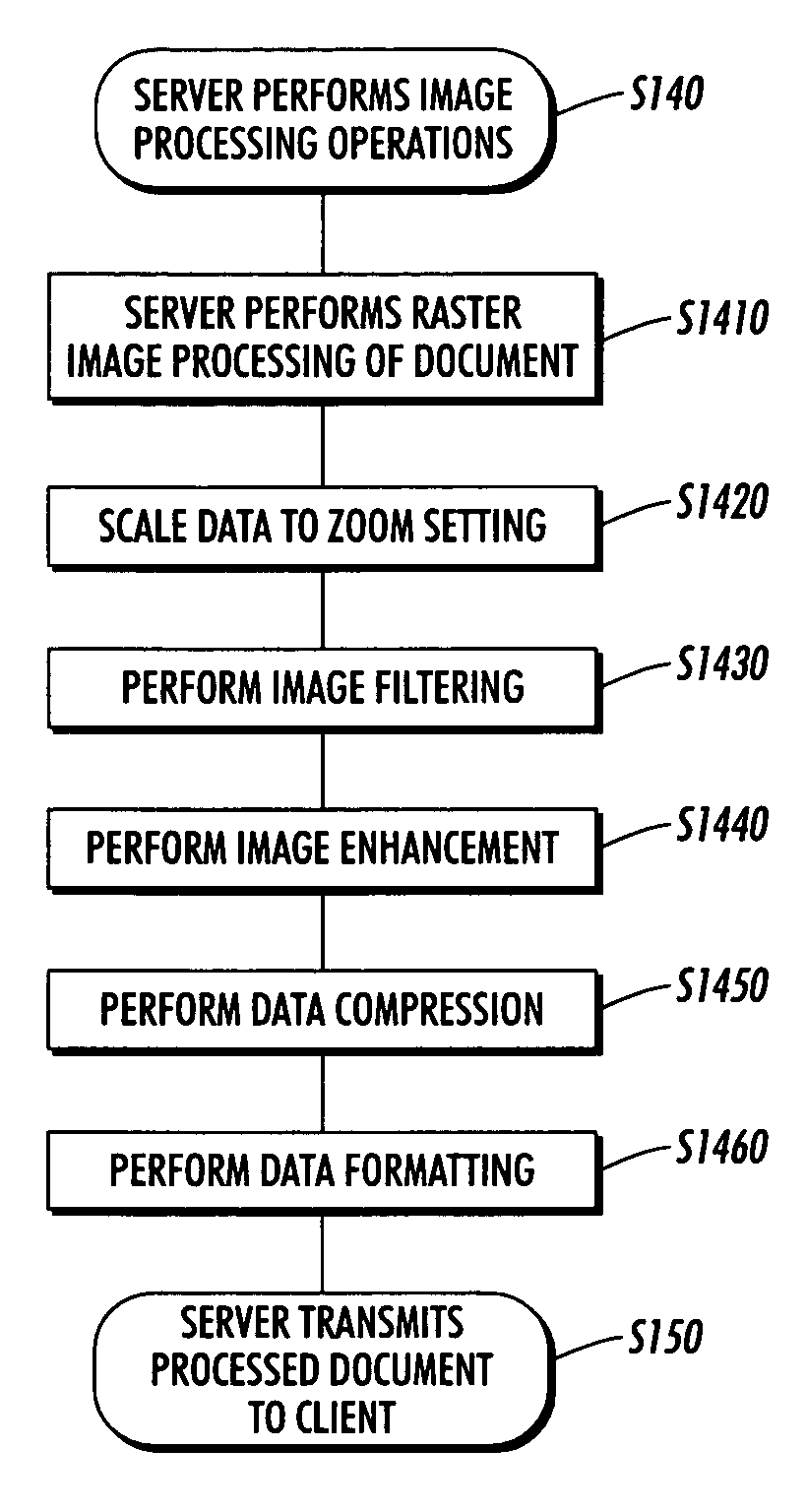

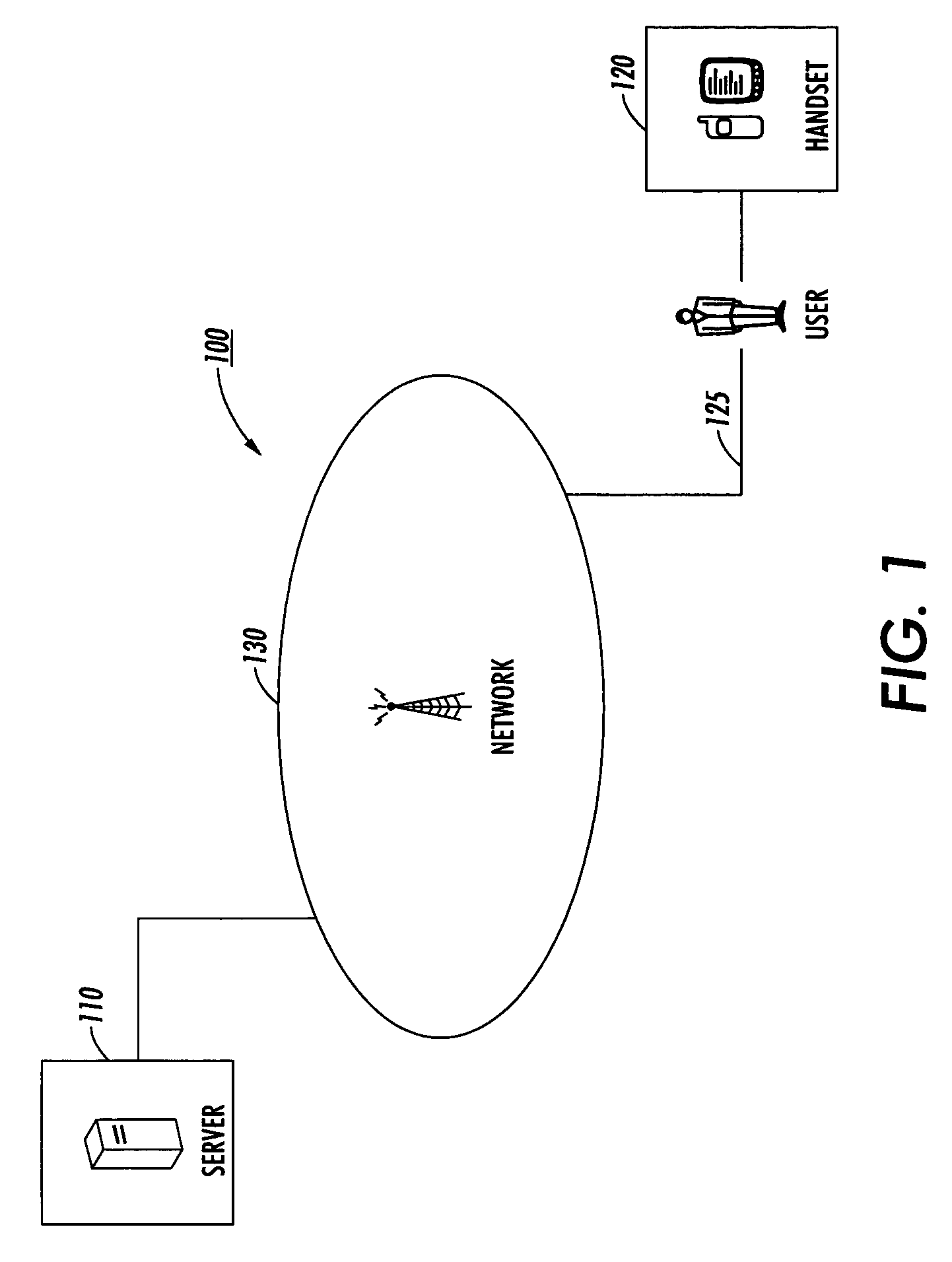

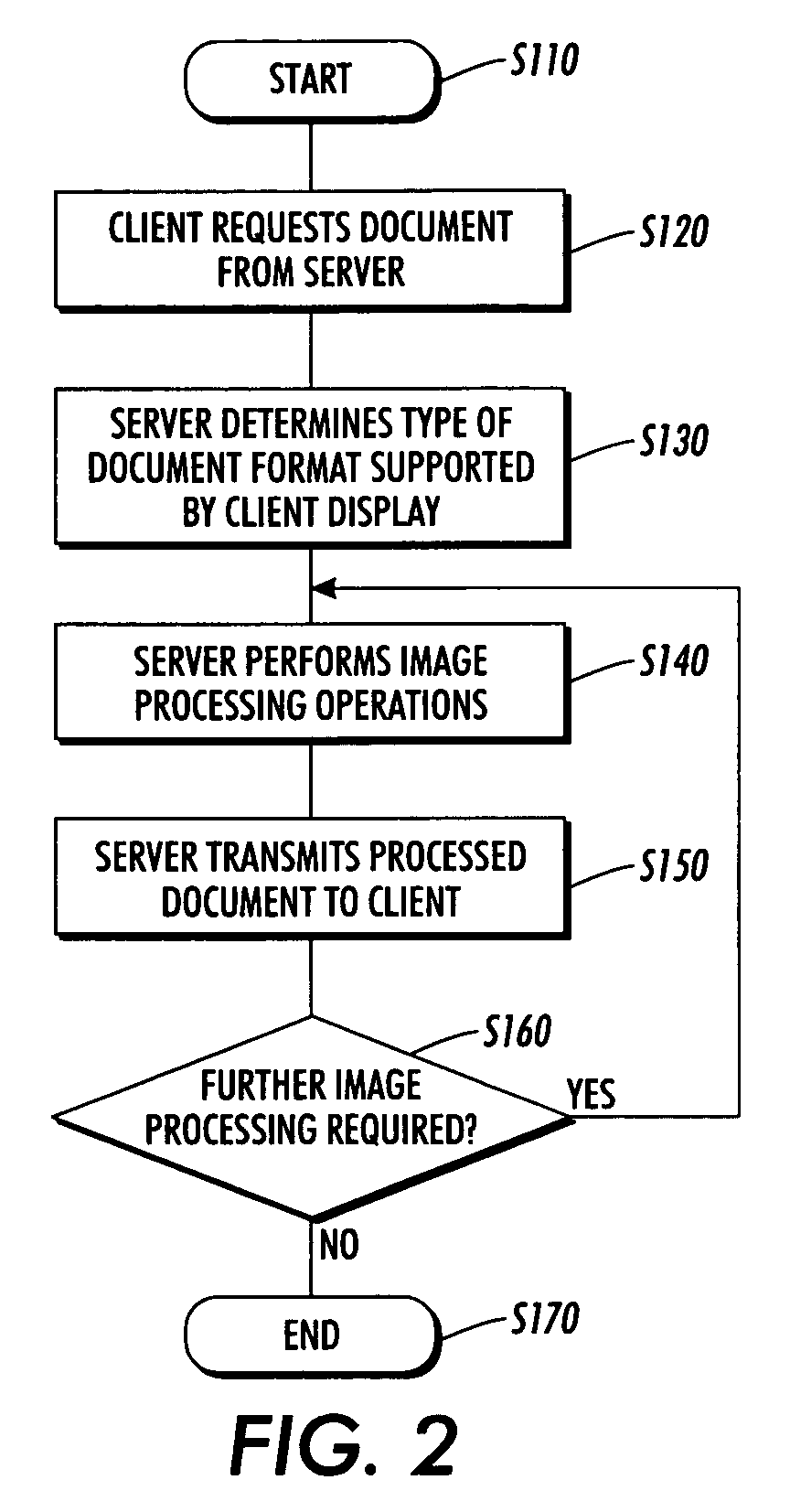

Server based image processing for client display of documents

InactiveUS7620892B2Lower upgradeCharacter and pattern recognitionImage data processing detailsImaging processingComputer graphics (images)

Methods and systems that allow the viewing of arbitrary documents on a client display by up-loading all necessary image processing steps to the server, thereby eliminating any software downloads to, or installation on, the client device.

Owner:INTEL CORP

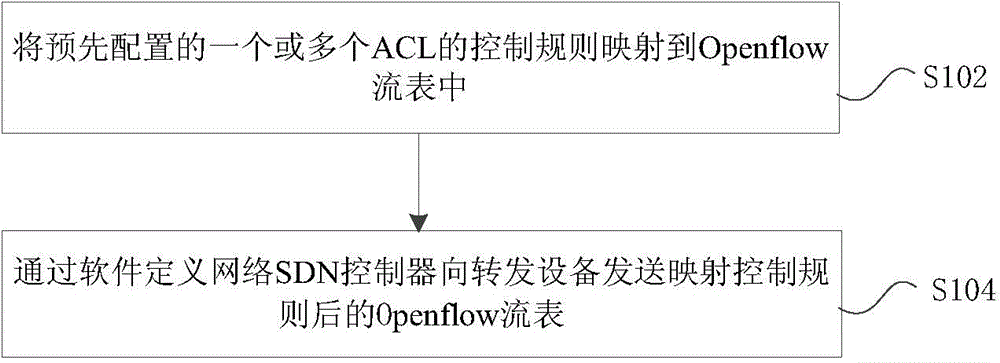

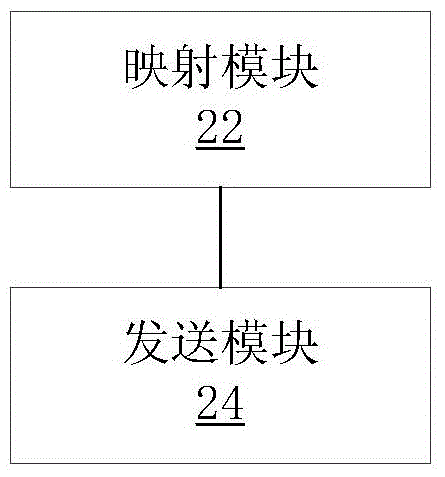

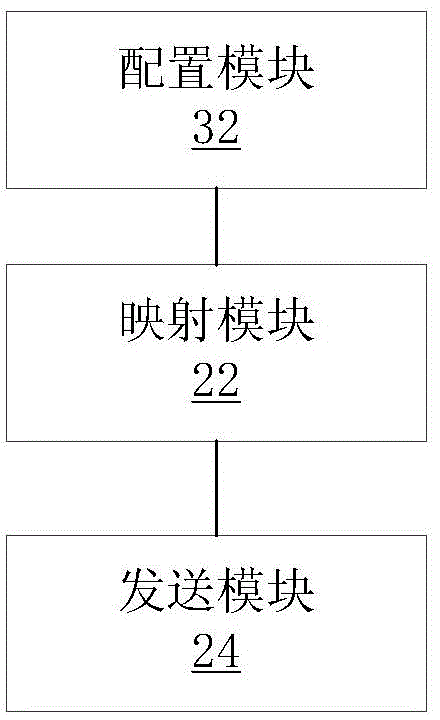

Method and device for sending access control list (ACL)

The invention provides a method and device for sending an access control list (ACL). The method comprises the steps that one or more pre-configured control rules of the ACL are mapped into an Openflow table; the Openflow table obtained after mapping of the control rules is sent through a software-defined network (SDN) controller. Through the method and device, the problems that a router is adopted for achieving the function of the ACL in related technologies, and the requirement for network equipment performance is very high are solved, and then the effect of relieving network equipment upgrading and maintenance is achieved.

Owner:ZTE CORP

Information processing apparatus and method

InactiveUS20100002874A1Ease of controlLower upgradeProgram control using stored programsResource allocationInformation processingInformation handling

The present invention relates to an information apparatus and method suitable for use in upgrading control programs readily by a user. In step S501, a storage area to store an upgraded firmware is determined. In step S502, the upgraded firmware is provided. In step 503, the provided firmware is decrypted and re-encrypted. In step S504, re-encrypted firmware is written into the storage area determined in step S501. In step S505, a maximum marker is detected. In step S506, a value obtained by adding 1 to the maximum marker provides the marker corresponding to the storage area in which the firmware was stored in step S504. The present invention is applicable to, for example, an audio data server.

Owner:SONY CORP

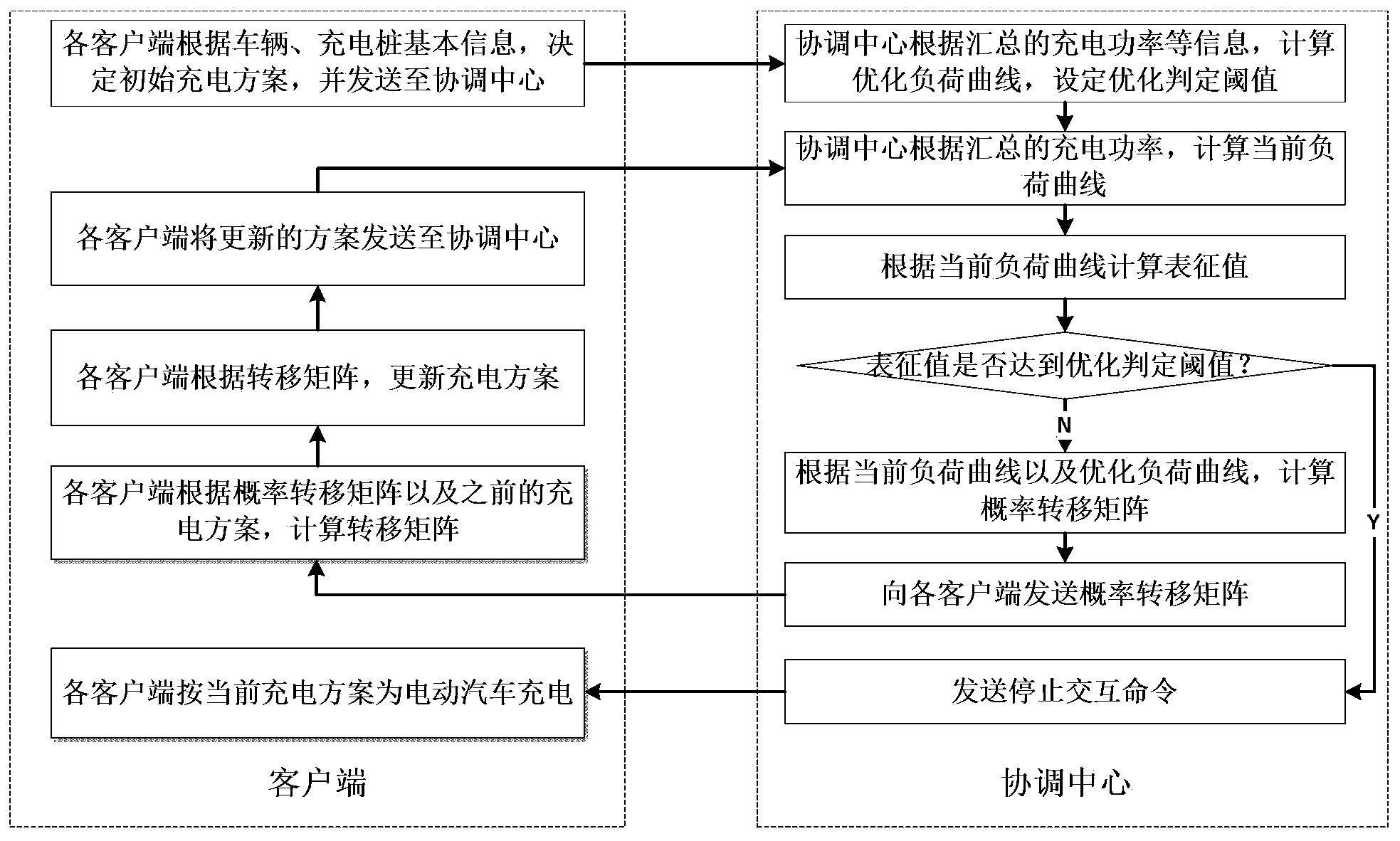

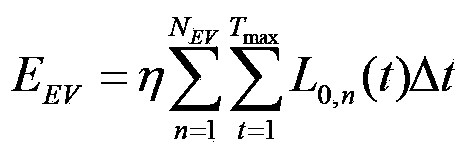

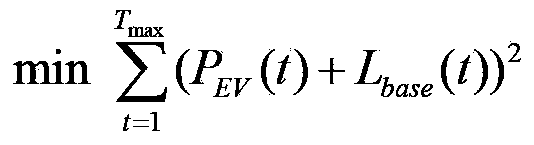

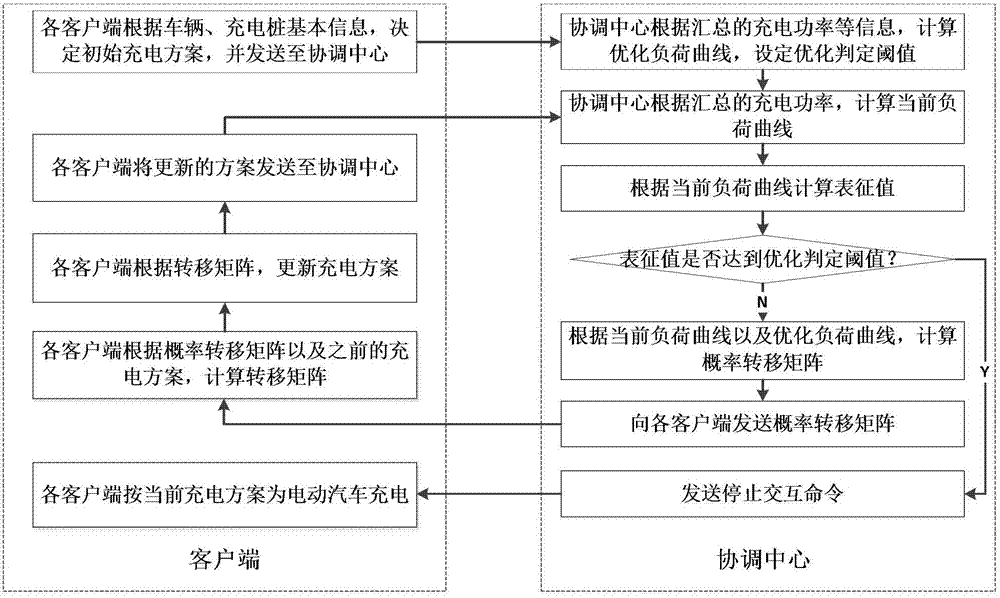

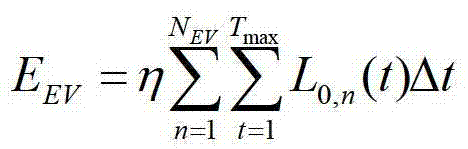

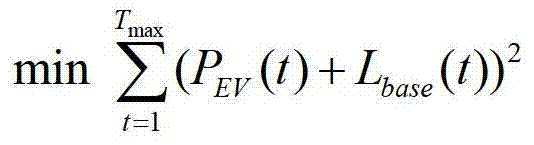

Distributed uniting coordination control method of large-scale electric automobile charging load

ActiveCN103457326AIncrease usageRealize peak shaving and valley staggered chargingBatteries circuit arrangementsElectric powerCurrent loadTransition probability matrix

The invention relates to a distributed uniting coordination control method of a large-scale electric automobile charging load, and belongs to the technical field of energy management. Client terminals determine and send the initial charging power to a coordination center according to basic information of an automobile. The coordination center calculates an optimized load curve and an optimized judging threshold value. A current load curve and a representation value of the current load curve are calculated according to the charging power of the client terminals. If the representation value is smaller than the judging threshold value, a stopping mutual order is sent, and the client terminals charge the electric automobile according to the charging power, and if not, a probability transfer matrix is calculated and is sent to the client terminals. The client terminals calculate a transfer matrix according to the probability transfer matrix, and the charging power is updated and sent to the coordination center. Interaction is executed repeatedly until the representation value is smaller than the judging threshold value. Staggering-peak charging can be effectively achieved, the calculating pressure of the coordination center is relieved, the charging demand privacy of a user is protected, the data communication resources between an upper layer and a lower layer are saved, and the distributed uniting coordination control method is suitable for orderly controlling large-scale electric automobiles.

Owner:STATE GRID CORP OF CHINA +3

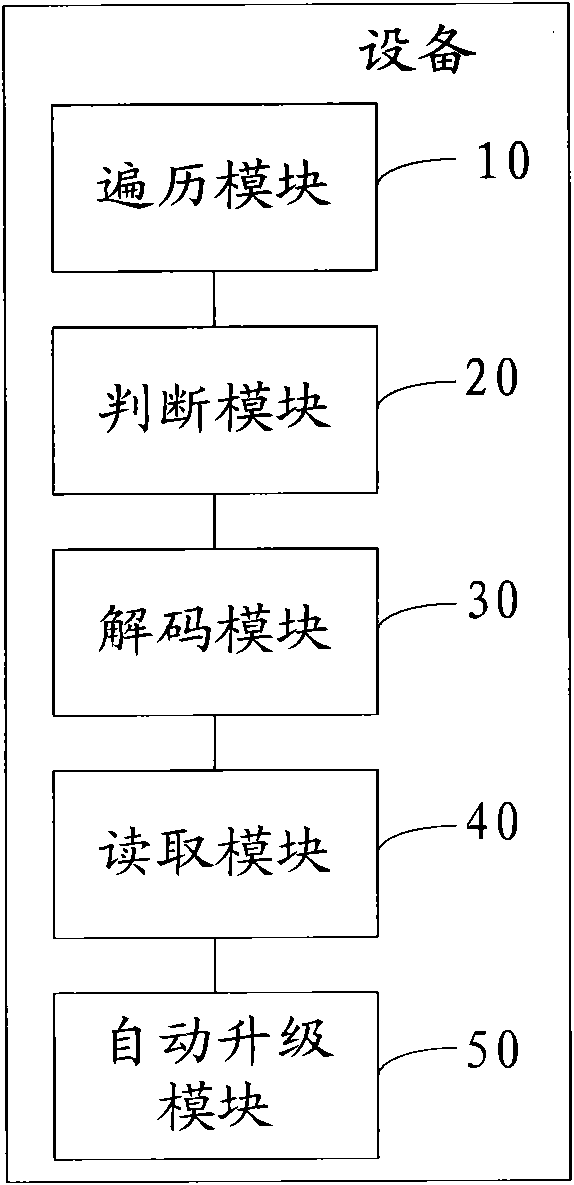

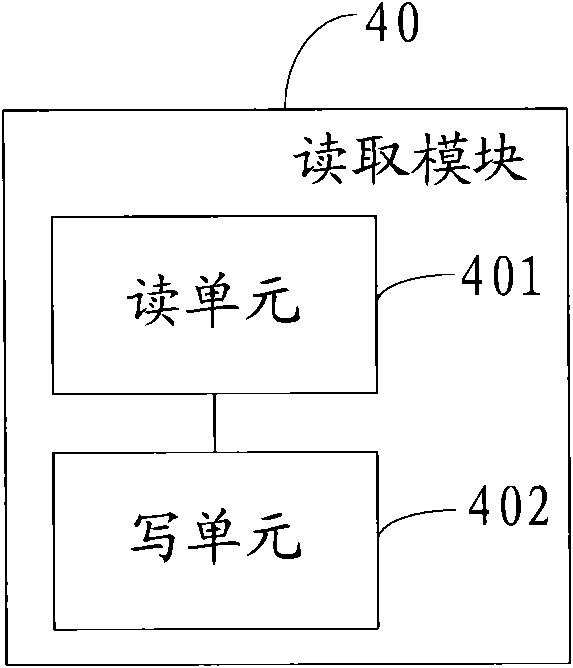

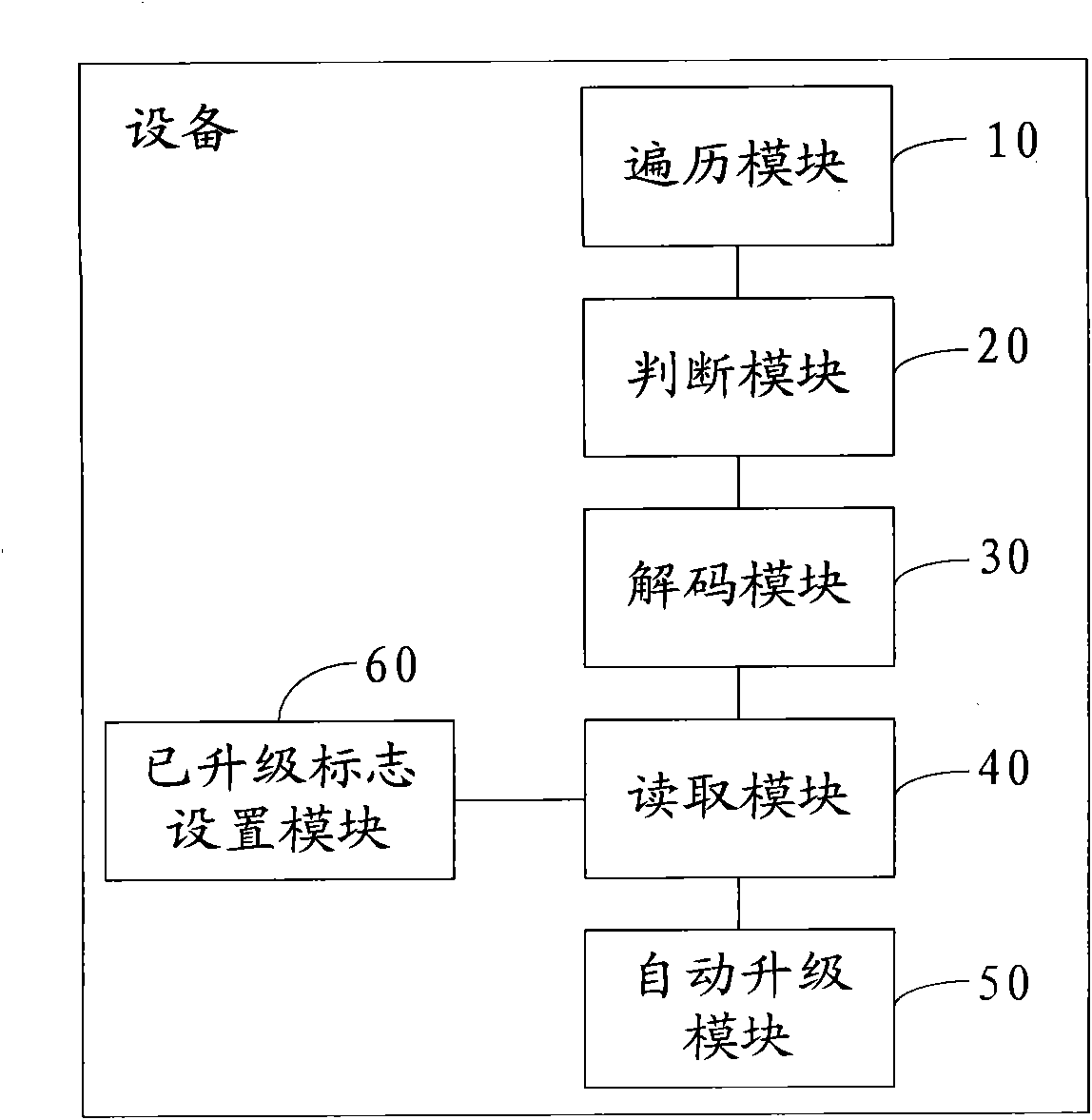

Automatic upgrading method for equipment and equipment

InactiveCN102012830AAvoid professionalismMeet the need for upgradesProgram loading/initiatingExpansion cardUpgrade

The embodiment of the invention discloses an automatic upgrading method for equipment, which comprises the following steps of: traversing an expansion card if the insertion of the expansion card is detected; judging whether the expansion card comprises an upgrade file or not; if the expansion card is judged to comprise the upgrade file, decoding the upgrade file and reading the decoded upgrade file; and automatically upgrading the equipment according to the read upgrade file. The embodiment of the invention also discloses the equipment. In the method and the equipment, the equipment can finish upgrading own firmware; and the method the equipment are simple in operation and practical.

Owner:LAUNCH SOFTWARE DEV

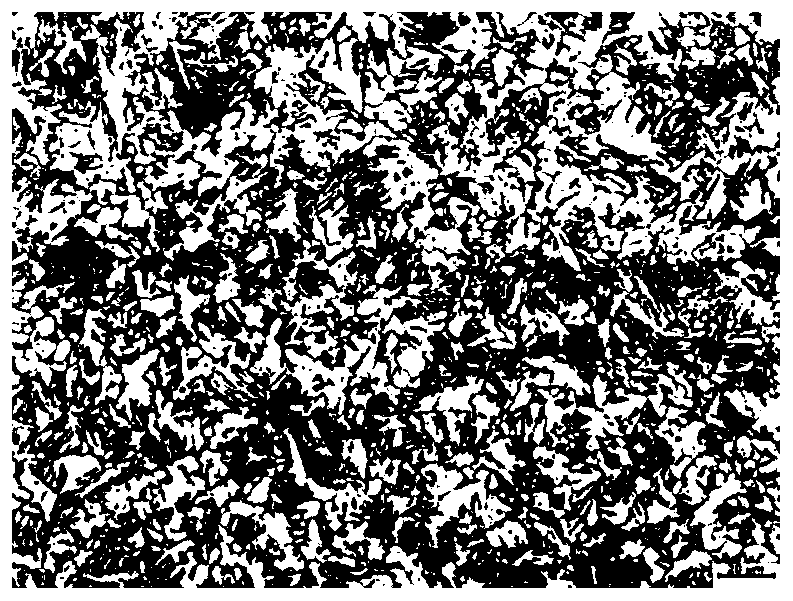

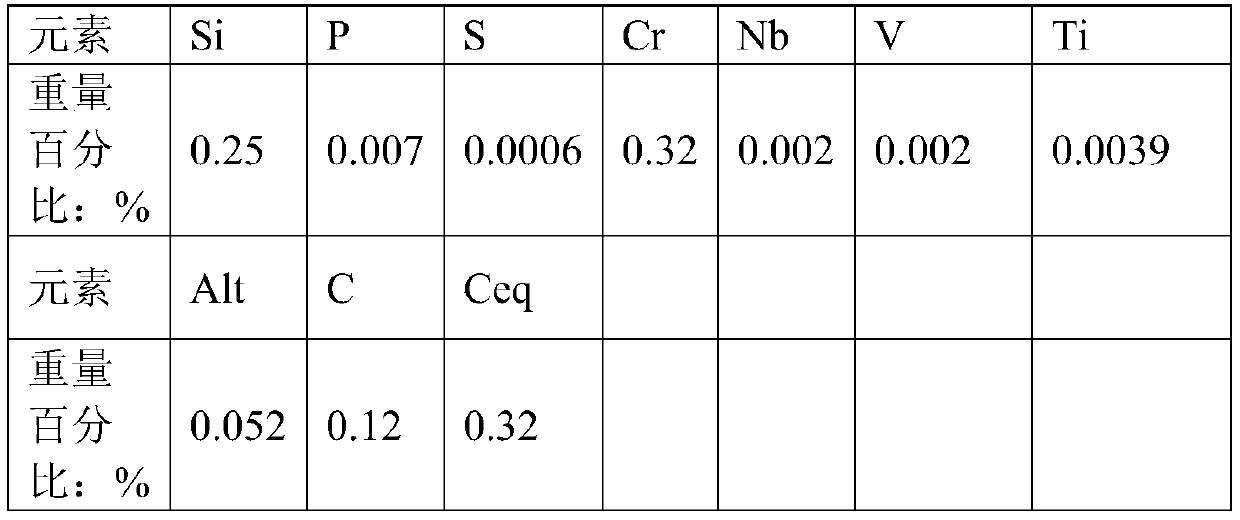

Method for producing ultra-low-temperature high-core-impact-value acid-resistant container steel by using casting blank

The invention discloses a method for producing an ultra-low-temperature high-core-impact-value acid-resistant container steel by using a casting blank. The method comprises the following steps of determining the steelmaking components; carrying out a heating process; carrying out a tapping and rolling process; and carrying out a heat treatment process. According to the method, the ultra-low-temperature high-core-impact-value acid-resistant container steel is produced through the design of being low in carbon and small in chromium alloy component amount in combination with the reasonable rolling control and cooling control, quenching and tempering and heat treatment processes, so that the mechanical property reaches the technical standard requirements, and the acid resistance meets the requirements of NACE-TM2084-2016, the actual level of the mechanical property reaches the following standards that the yield strength is greater than or equal to 340 MPa, the tensile strength is greater than or equal to 480 MPa, the elongation is greater than or equal to 35%, the transverse Akv at the core of a steel plate and at 60 DEG C below zero is greater than or equal to 240 J, the HIC resistance reaches the standards that CLR is equal to 0%, CTR is equal to 0%, and the CSR is equal to 0%, and therefore, the problems of unstable low-temperature impact property, poor HIC resistance, unstableweldability and the like of the production of the ultra-low-temperature high-core-impact-value by using a casting blank in the prior art are solved.

Owner:NANJING IRON & STEEL CO LTD

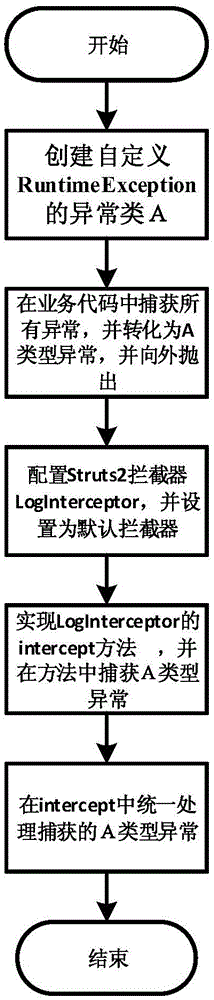

Excellent exception processing method

InactiveCN105005508AWill not affect normal operationSimple exception handlingFault responseProcess mechanismWeb development

The present invention relates to the field of JAVA technology WEB development, and particularly relates to an excellent exception processing method. The method comprises: when a code of a platform throws an exception, transforming the exception into an exception type A of a RuntimeException type, and throwing out the exception type A again instead of performing any processing; further configuring the platform with a Struts2 interceptor and setting the interceptor as a default interceptor, capturing an A type exception, and performing uniform processing; and when an exception processing mechanism changes, changing a method of the interceptor. According to the present invention, the efficiency problem of processing the exception in J2EE is effectively solved; and the method can be applied to exception processing of the J2EE.

Owner:G CLOUD TECH

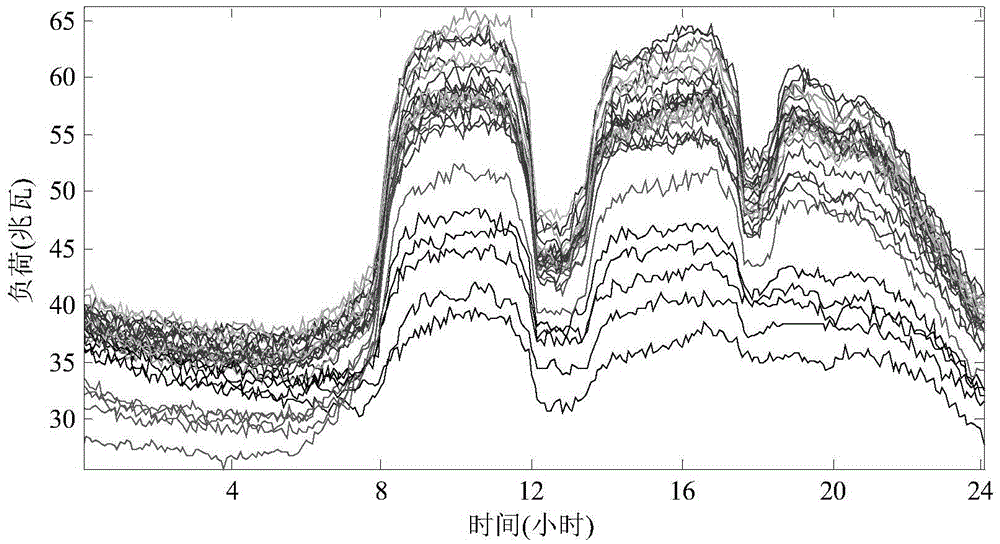

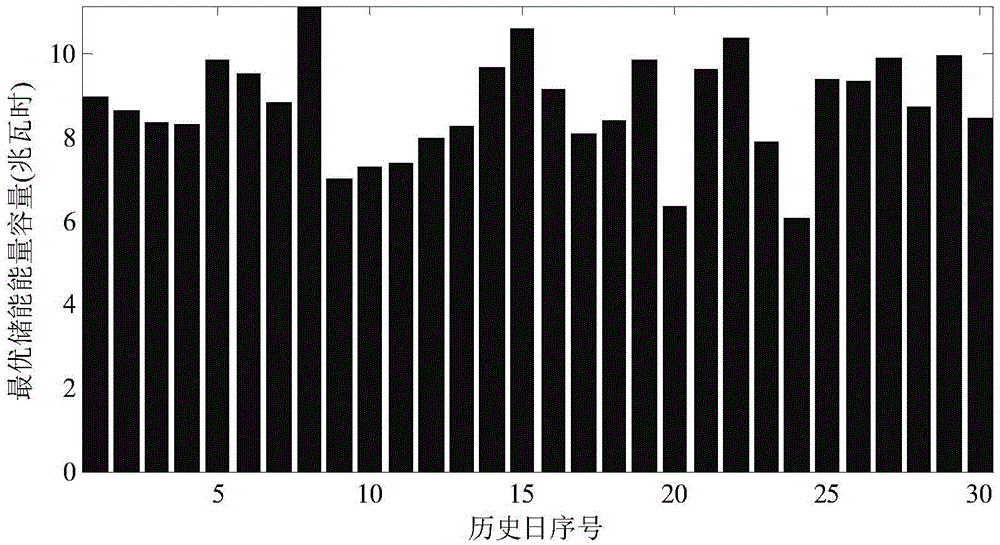

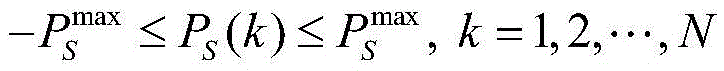

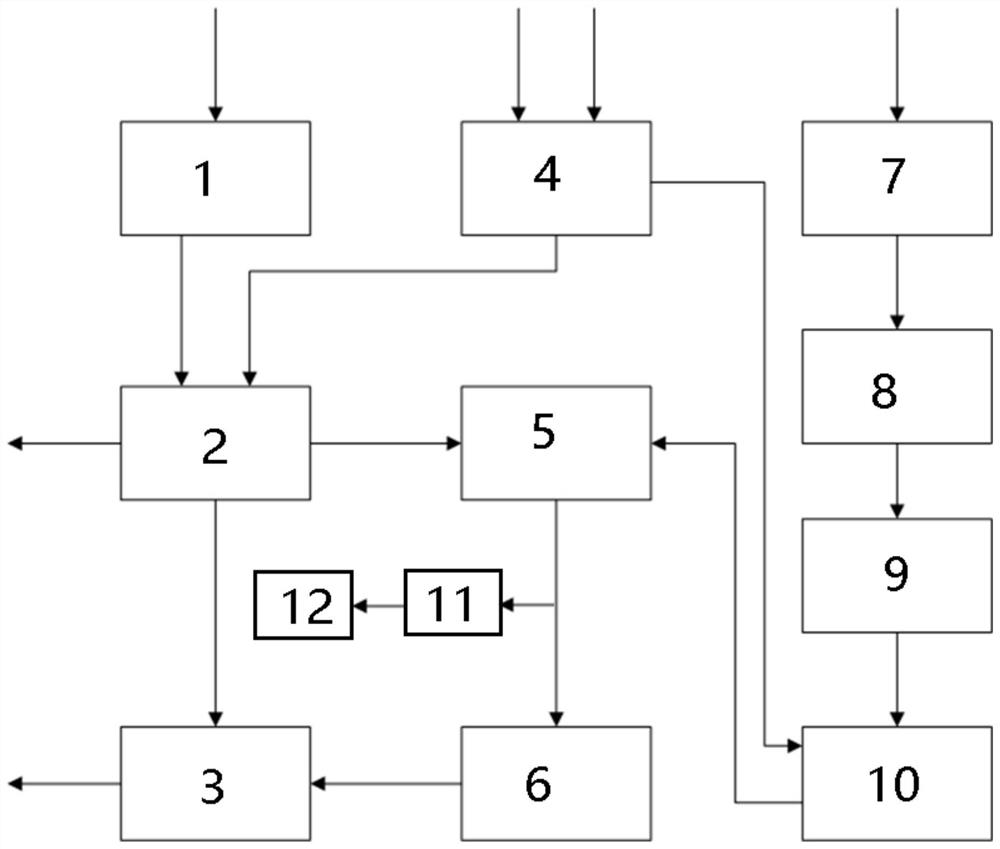

A Calculation Method for Optimal Capacity of Energy Storage System for Load Shaving and Valley Filling

ActiveCN103972915BRelieve stressLower upgradeAc network load balancingSpecial data processing applicationsElectric power systemPower grid

The invention relates to an energy storage system optimum capacity calculating method for peak load shifting and belongs to the technical field of electric power system optimization calculation. According to the method, an energy storage system energy capacity optimization model used for peak load shifting is built, then, constraint conditions for the energy storage system energy capacity optimization model used for peak load shifting are set, a quadratic programming solving method is adopted for solving a quadratic programming model, and the optimum energy capacity of an energy storage system is obtained. According to the method, on the basis of historical load data, the energy storage system energy capacity needed for meeting the appointed peak load reduction quantity can be calculated, pressure of peak loads on a power grid is effectively relieved, and upgrading of an electric power system device is delayed.

Owner:SOUTHERN POWER GRID PEAK LOAD & FREQUENCY REGULATION GENERATING CO LTD +1

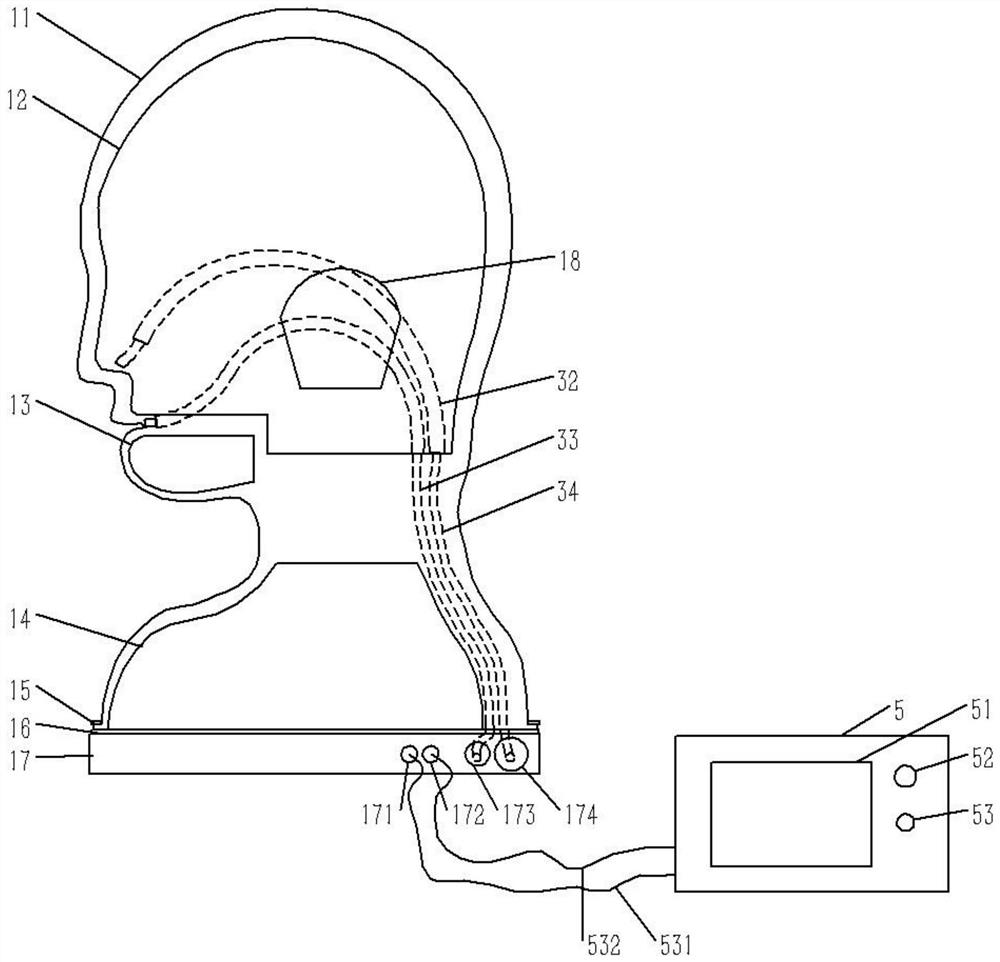

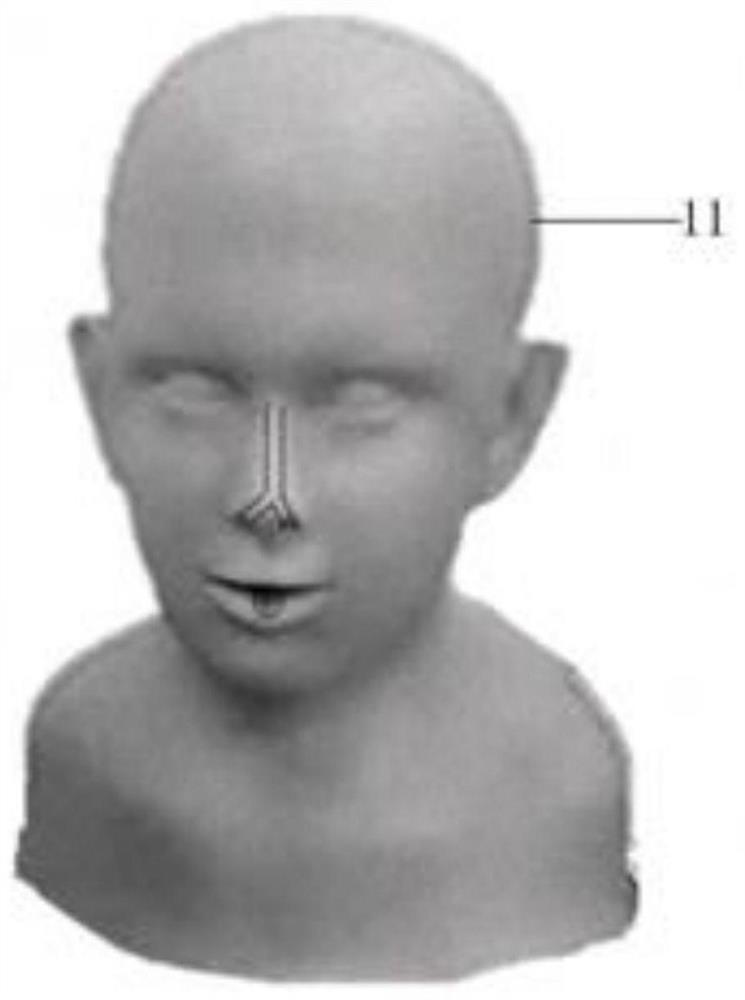

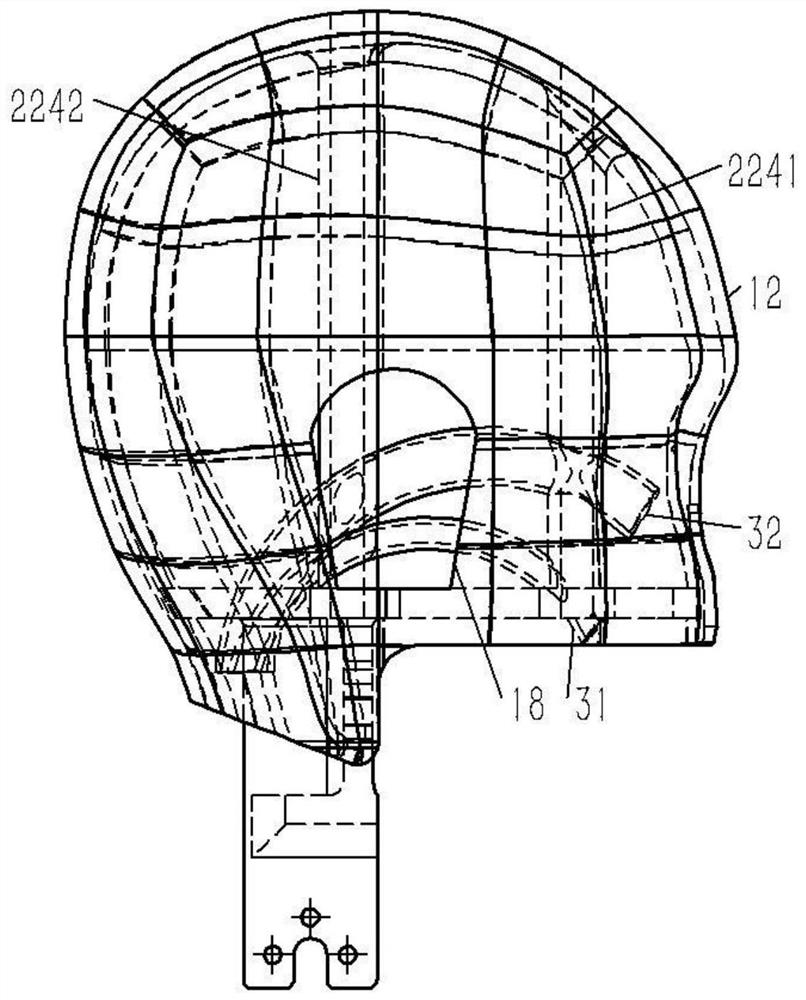

Intelligent humanoid head model for testing child mask and child mask testing method

PendingCN111781125AAvoid vibrationMitigate high occupancyProgramme controlComputer controlNasal passagesSimulation

The invention discloses an intelligent humanoid head model for testing a child mask and a child mask testing method. The intelligent humanoid head model comprises a head model outer sleeve, a head model inner shell, a control box, a head shaking mechanism arranged in the head model inner shell, a nodding mechanism, a mouth opening and closing mechanism, a nasal cavity hose and an oral cavity hose.The control box controls the humanoid head model to complete head shaking motion, nodding motion and mouth opening and closing motion in the mask tester, and detection of the child mask is completed.The defects that in the prior art, due to imperfect design of all action mechanisms, accumulated errors are large, too much space is occupied, and vibration is prone to occurring in the movement process, a control system is difficult to maintain in the later period, and angle information cannot be fed back in real time are overcome. The movement precision of the movement mechanism is improved, the occupied space is reduced, and the oral-nasal cavity catheter and the angle sensor are reasonably arranged to achieve real-time feedback of angle information in the movement process.

Owner:佛山市顺德致可智能科技有限公司

Distributed uniting coordination control method of large-scale electric automobile charging load

ActiveCN103457326BIncrease usageRealize peak shaving and valley staggered chargingBatteries circuit arrangementsElectric powerCurrent loadTransition probability matrix

The invention relates to a distributed uniting coordination control method of a large-scale electric automobile charging load, and belongs to the technical field of energy management. Client terminals determine and send the initial charging power to a coordination center according to basic information of an automobile. The coordination center calculates an optimized load curve and an optimized judging threshold value. A current load curve and a representation value of the current load curve are calculated according to the charging power of the client terminals. If the representation value is smaller than the judging threshold value, a stopping mutual order is sent, and the client terminals charge the electric automobile according to the charging power, and if not, a probability transfer matrix is calculated and is sent to the client terminals. The client terminals calculate a transfer matrix according to the probability transfer matrix, and the charging power is updated and sent to the coordination center. Interaction is executed repeatedly until the representation value is smaller than the judging threshold value. Staggering-peak charging can be effectively achieved, the calculating pressure of the coordination center is relieved, the charging demand privacy of a user is protected, the data communication resources between an upper layer and a lower layer are saved, and the distributed uniting coordination control method is suitable for orderly controlling large-scale electric automobiles.

Owner:STATE GRID CORP OF CHINA +3

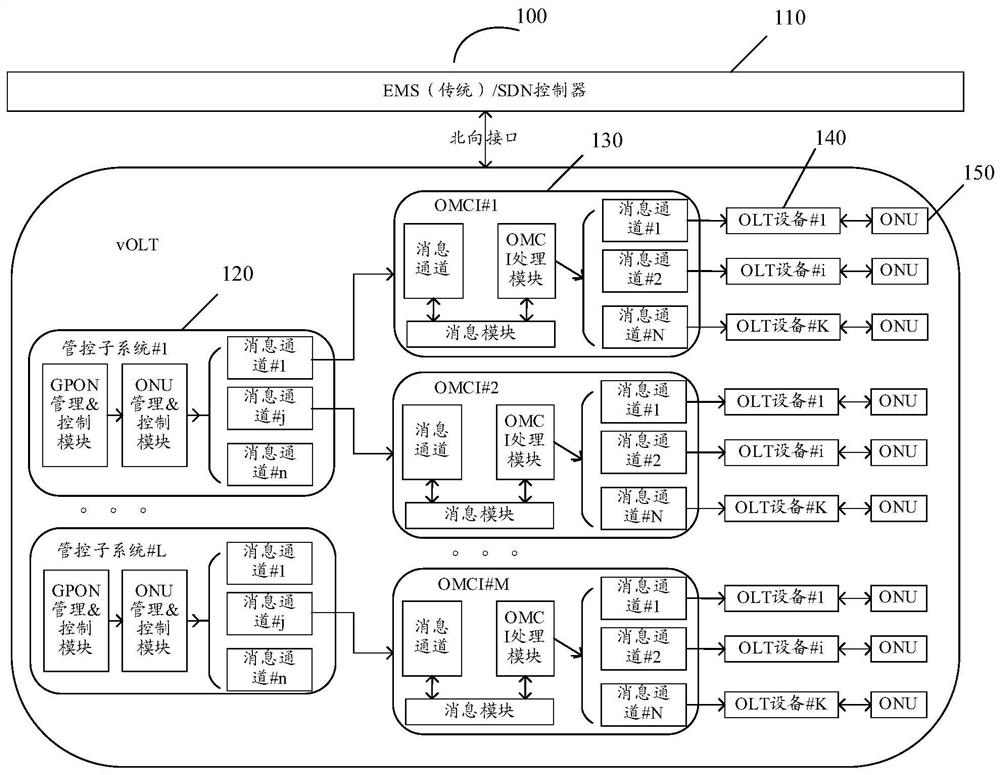

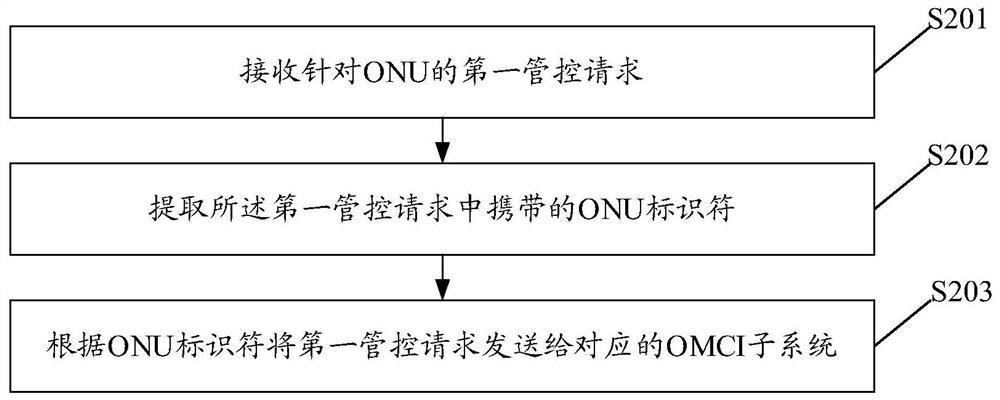

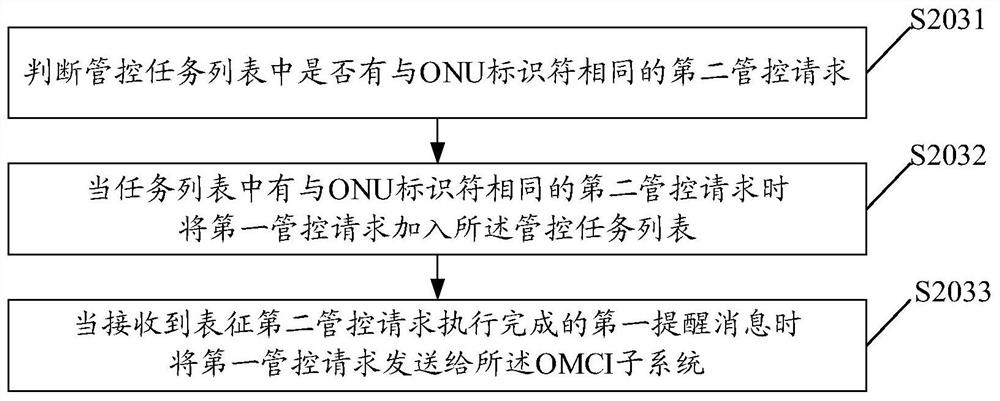

ONU management method, device, equipment and system

ActiveCN113068085AReduce complexityLower upgradeMultiplex system selection arrangementsEngineeringReal-time computing

The embodiment of the invention provides an ONU management method, device, equipment and system, and the method comprises the steps: receiving a first management and control request for an ONU; extracting an ONU identifier carried in the first management and control request, sending the first management and control request to a corresponding OMCI subsystem according to the ONU identifier, so that the OMCI subsystem generates an OMCI data packet according to the first management and control request and sends the OMCI data packet to a corresponding OLT device, and the OLT device manages and controls the ONU based on the OMCI data packet.

Owner:CHINA MOBILE COMM LTD RES INST +1

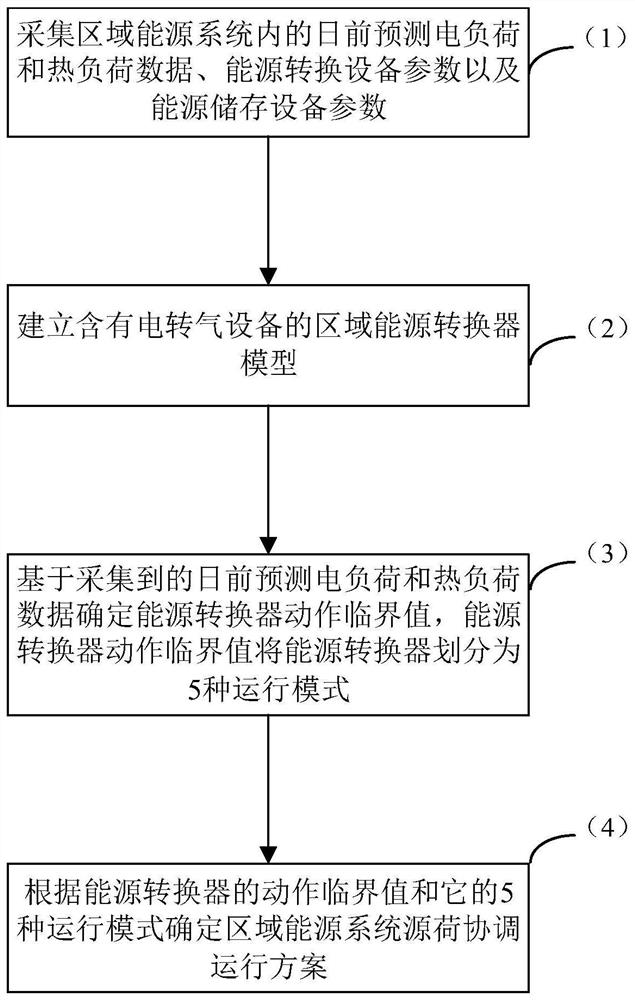

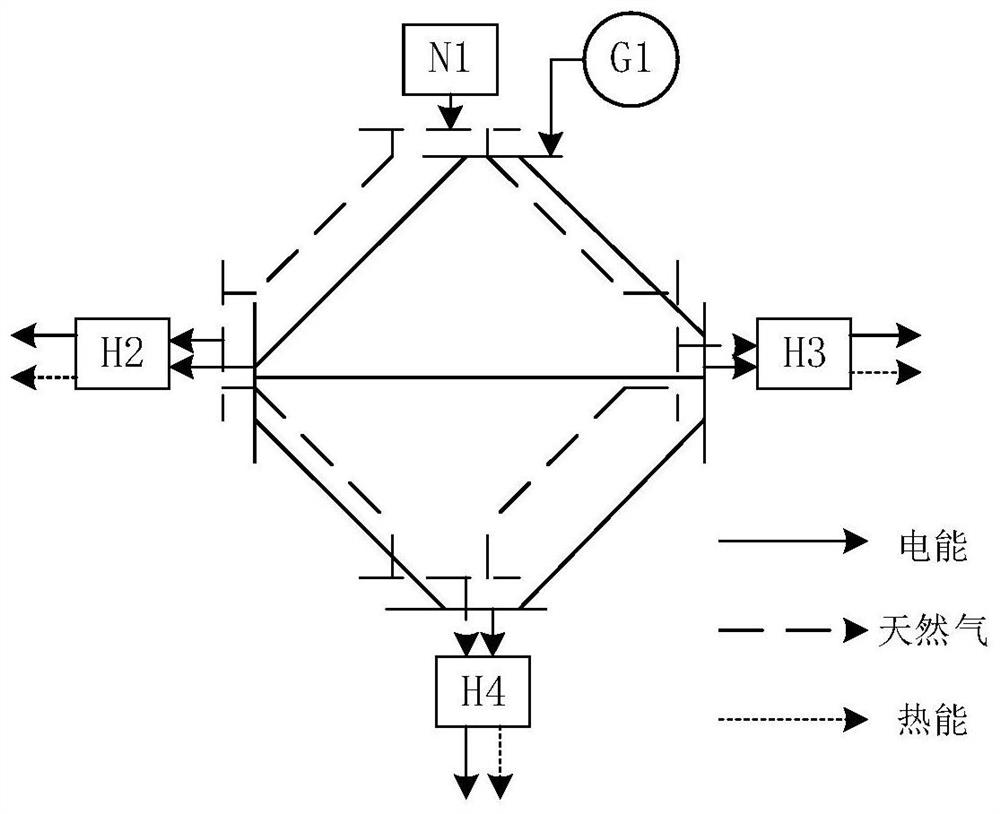

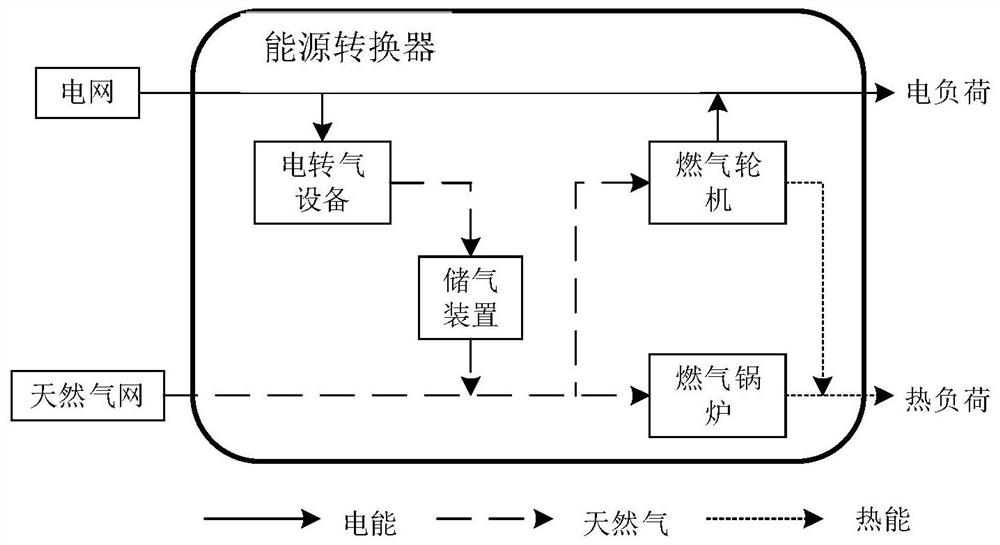

Regional energy system source-load coordinated operation simple method based on electricity-to-gas conversion equipment

ActiveCN111899121AReduce capacity buildingLower upgradeData processing applicationsDesign optimisation/simulationConvertersPower to gas

The invention provides a regional energy system source-load coordinated operation simple method based on electricity-to-gas conversion equipment. The method comprises the following steps: collecting day-ahead prediction electrical load and thermal load data, energy conversion equipment parameters and energy storage equipment parameters in a regional energy system; establishing a regional energy converter model containing the electricity-to-gas conversion equipment according to the acquired energy conversion equipment parameters and the energy storage equipment parameters; determining an actioncritical value of the energy converter based on the acquired day-ahead prediction electrical load and thermal load data, and dividing the energy converter into five operation modes according to the action critical value of the energy converter; and determining a source-load coordinated operation scheme of the regional energy system according to the action critical value of the energy converter and the five operation modes of the energy converter. The method is convenient to operate, peak clipping and valley filling are conducted on electric loads through multi-energy complementation, unit capacity construction can be reduced, power grid upgrading is delayed, and natural gas, electric energy and heat energy markets are promoted to be connected more closely.

Owner:SHENZHEN POLYTECHNIC

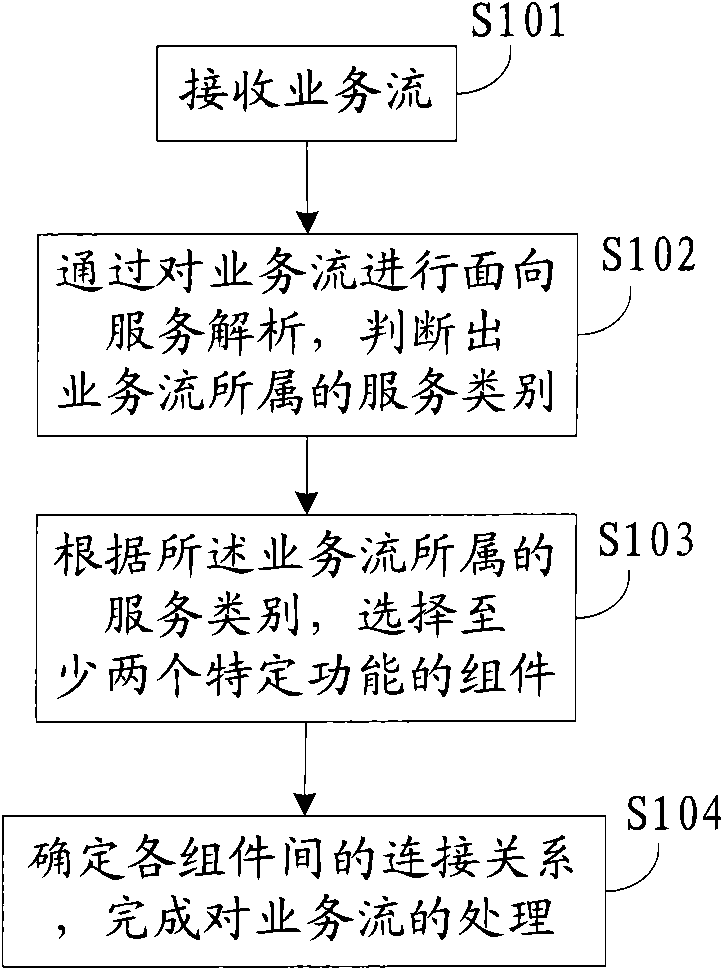

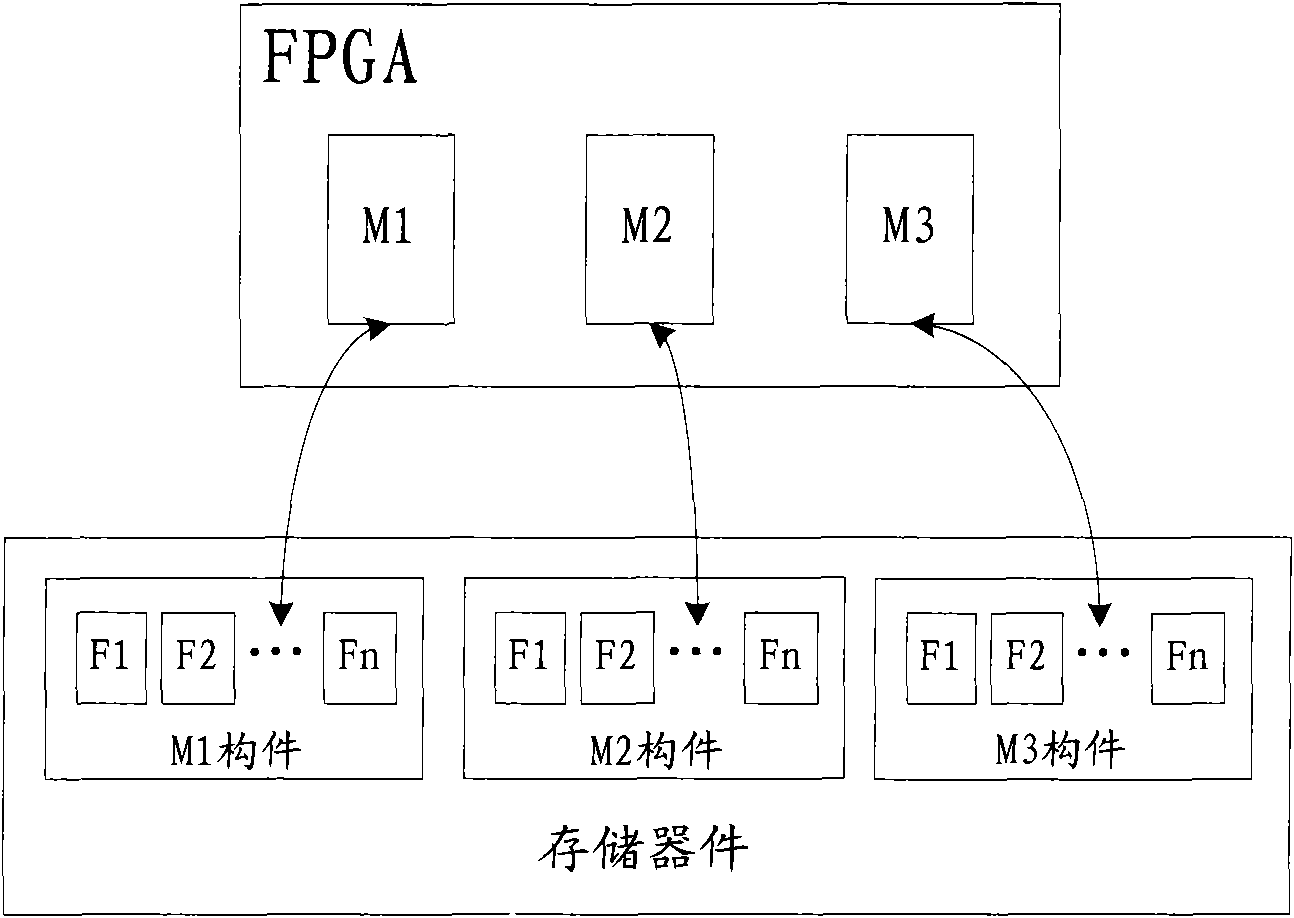

Method and device for processing business flow

InactiveCN101577663AReduce complexityAvoid wastingData switching networksSoftware engineeringClass of service

The invention discloses a method for processing business flow, which comprises the following steps: performing the service-oriented analysis to the business flow, judging classes of service attributed by the business flow; selecting at least two assemblies with special functions according to the classes of service attributed by the business flow; determining the connection relation among the assemblies, and completing the processing of the business flow. The invention also discloses a device for processing the business flow, which can realize the reconfigurable design of the assemblies or components aiming at different processing tasks, reduces the whole equipment upgrading or updating caused by network business change, avoids the waste caused by the investment of the original equipment resource, reduces the network complexity, increases the processing speed, and is beneficial to developing multiple flexible businesses and flexibly disposing the future business. In addition, the invention can realize that the network equipment is built based on unified assemblies and components, can break the situation that less well-known companies monopolize and divide up the technology of high-end route exchange equipment, and fully realizes the openness.

Owner:THE PLA INFORMATION ENG UNIV

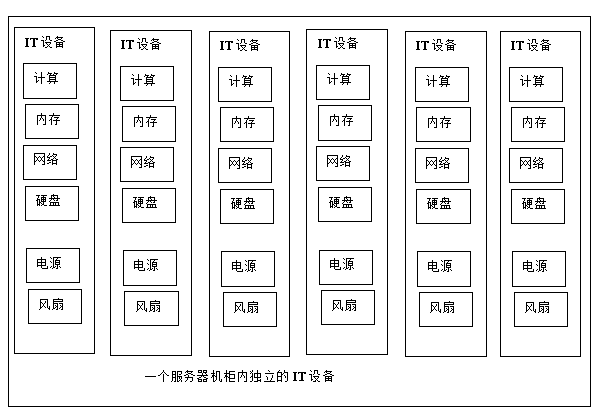

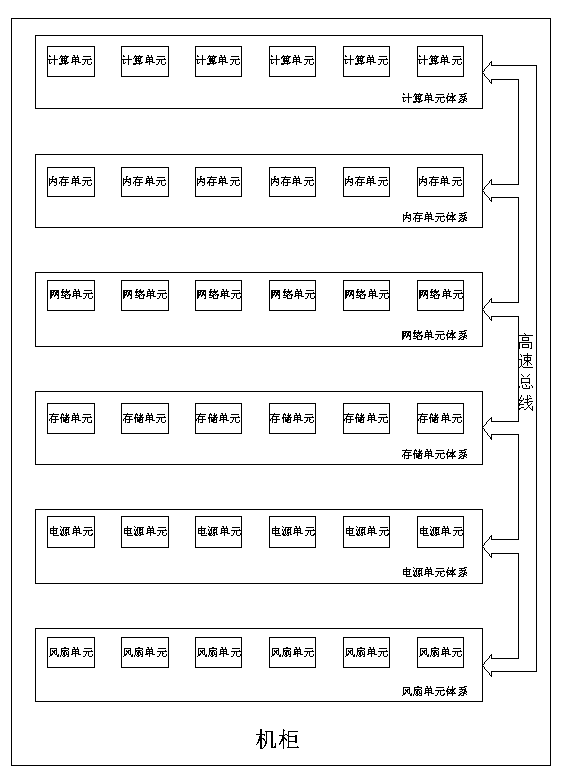

Integral cabinet server with centralized functions and configuration method thereof

The invention discloses an integral cabinet server with centralized functions and a configuration method thereof and belongs to servers. According to the integral cabinet server with centralized functions, a plurality of servers are arranged in a cabinet, and power units, fan units, calculation units, memory units, network units and storage units of all the servers in the cabinet are integrated into a whole respectively to form a power unit system, a fan unit system, a calculation unit system, a memory unit system, a network unit system and a storage unit system which are relatively independent and interconnected through high-speed bus to form an integral cabinet server with the cabinet serving as the unit. By means of the integral cabinet server with centralized functions and the configuration method of the integral cabinet server with centralized functions, functions are centralized, functions of systems are modularized, and therefore, demands of business changes can be met by replacing corresponding function modules when functions are changed.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

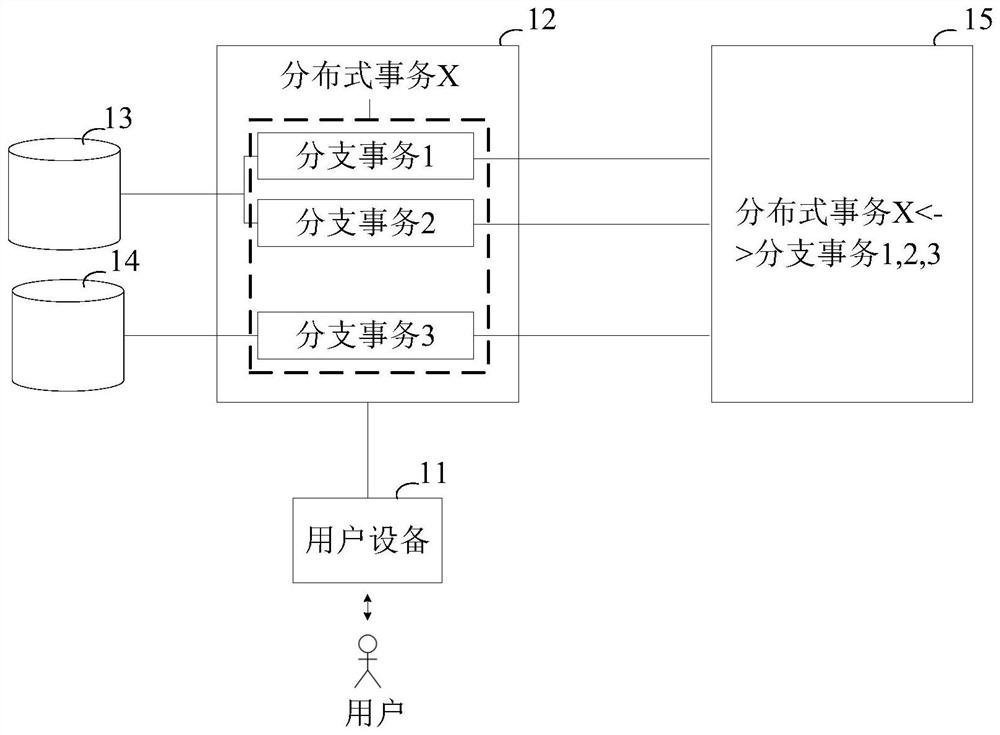

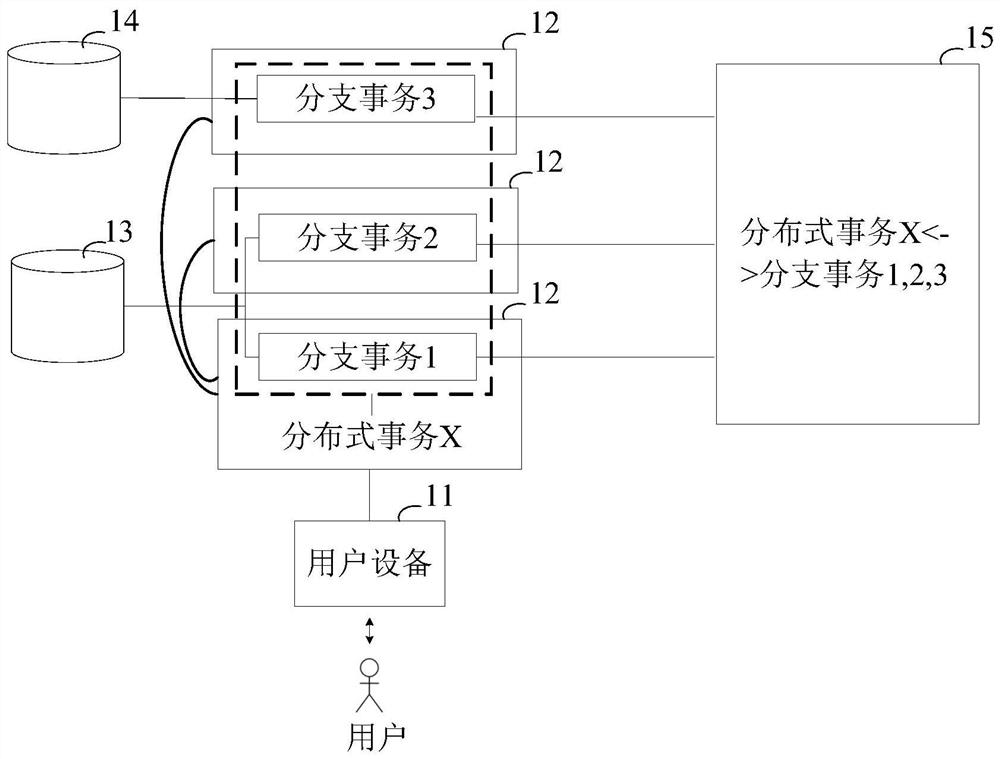

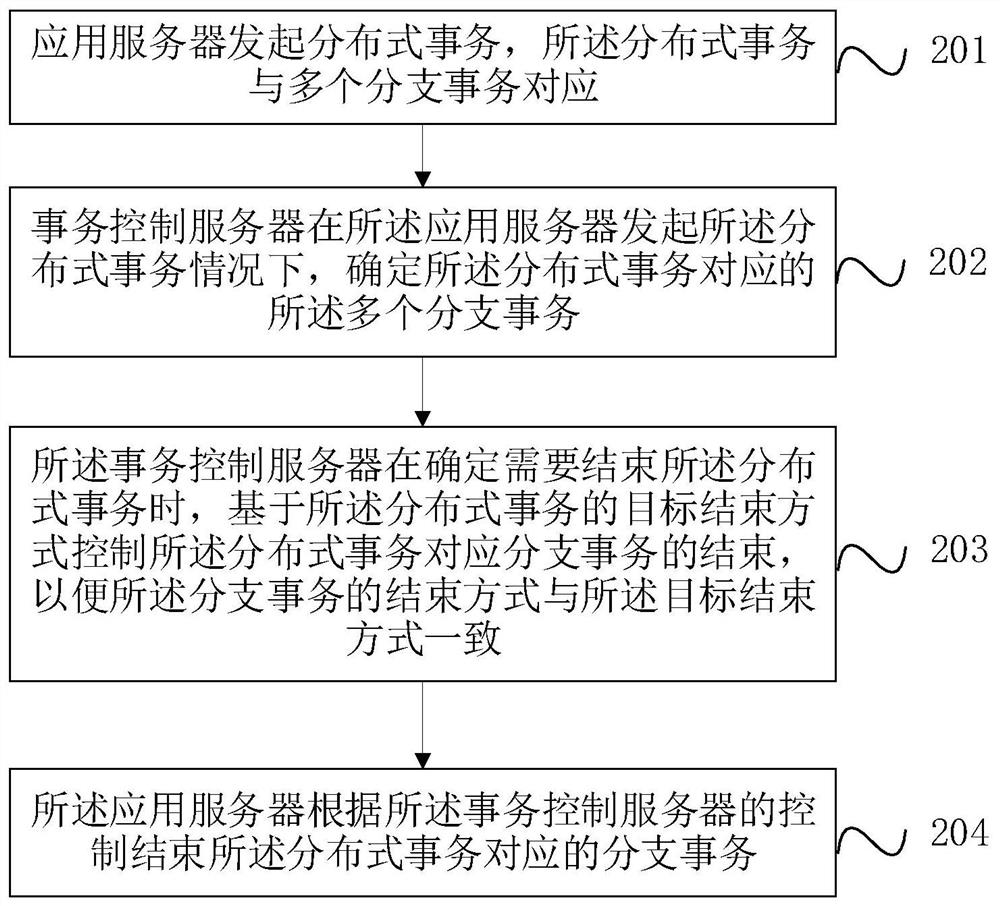

Distributed transaction processing method, device and equipment

ActiveCN113296896BEasy to implementLower upgradeTransaction processingApplication serverParallel computing

Owner:ALIBABA CLOUD COMPUTING LTD

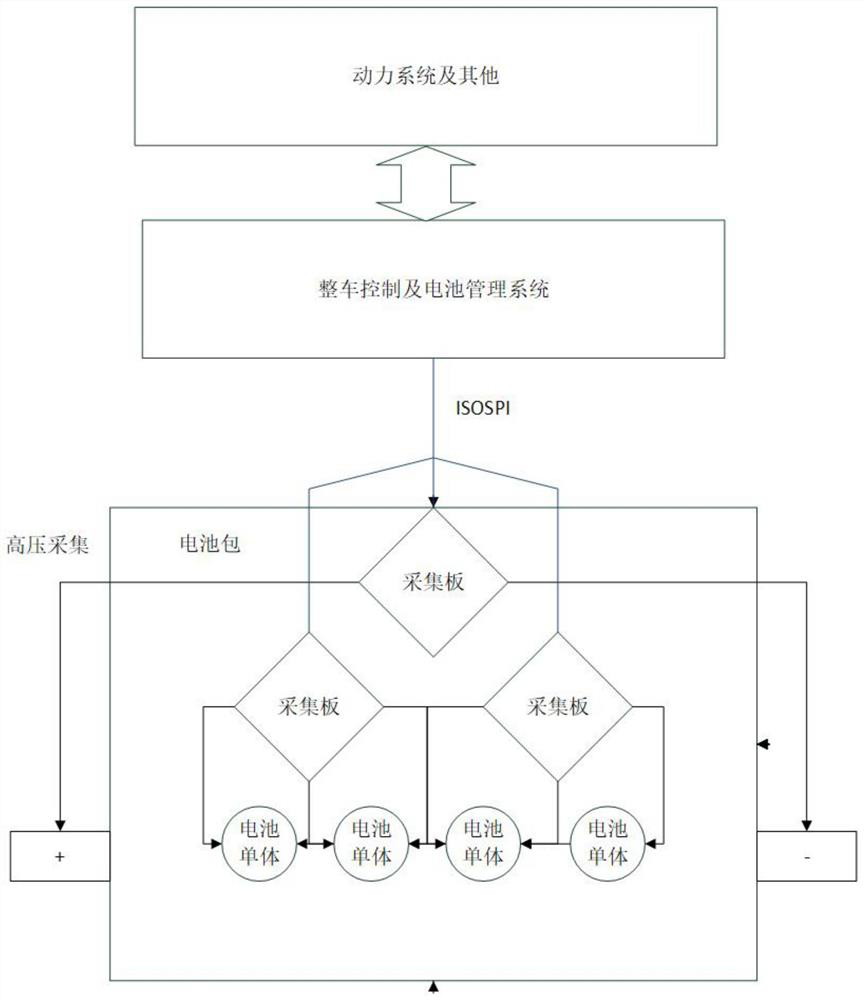

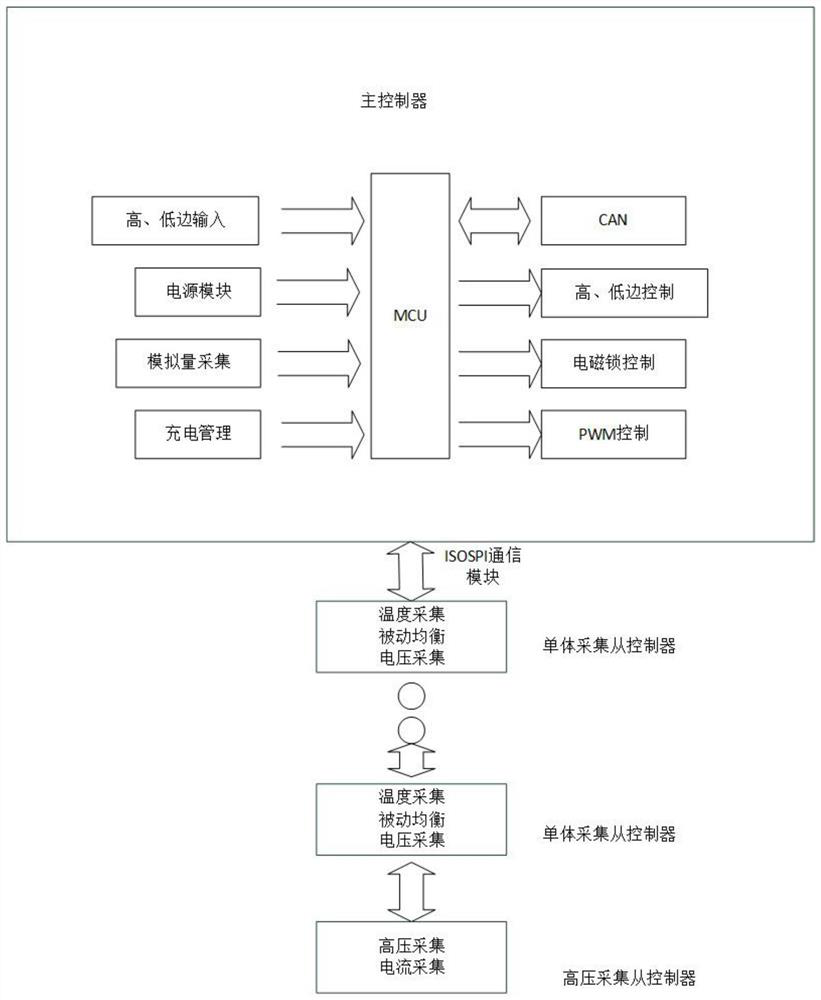

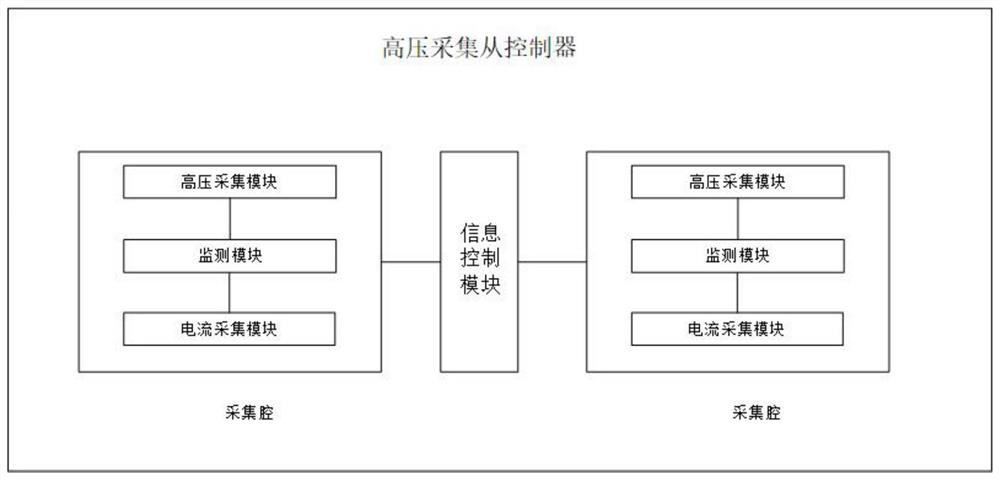

A control system integrating battery management and vehicle control functions

ActiveCN110254292BMultiple choiceReduce security risksElectric vehicle charging technologyVehicular energy storageInformation controlControl system

The invention discloses a control system integrating battery management and vehicle control functions, which is characterized in that it includes a main controller, a single acquisition slave controller, a high-voltage acquisition slave controller and an ISOSPI communication module, and the high-voltage acquisition slave controller The detector includes an information control module and several collection chambers, and each collection chamber includes a high-voltage collection module, a current collection module and a monitoring module. The present invention realizes the separation of high and low pressure from the structure of the whole vehicle; the position of the main controller is more selective in the layout of the whole vehicle; the backup and monitoring of several collection chambers make the data collection more stable.

Owner:杭州云弘汽车技术有限公司

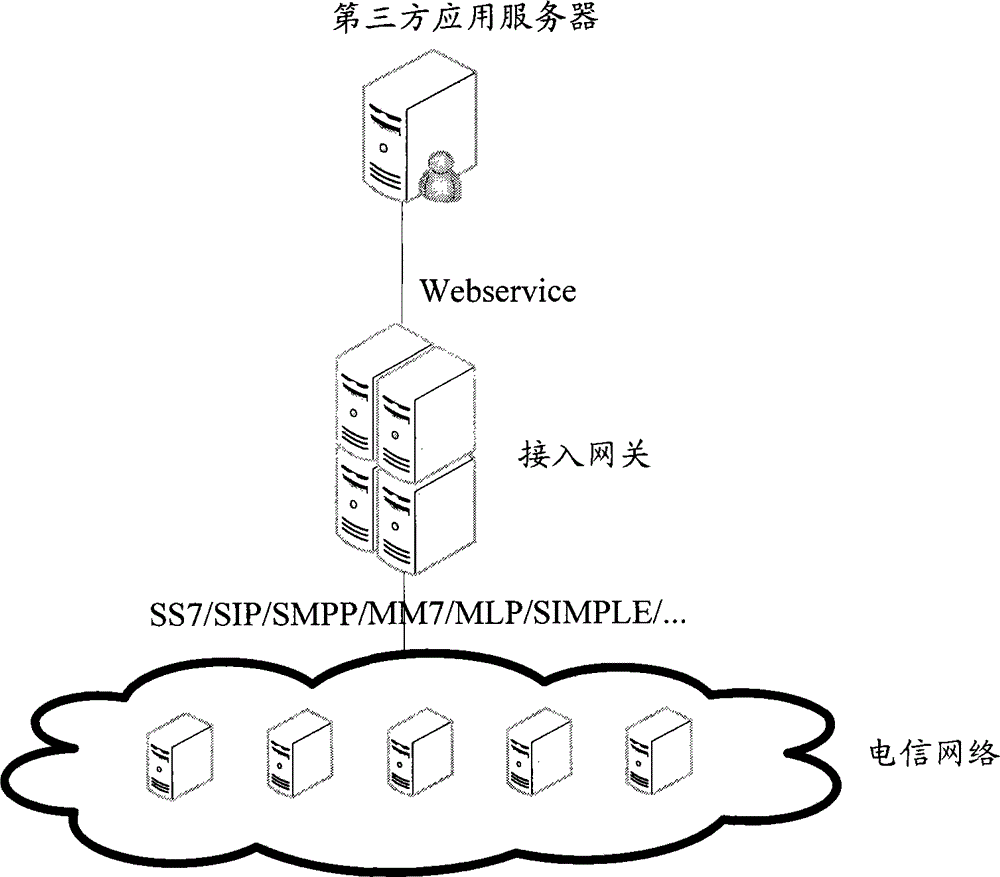

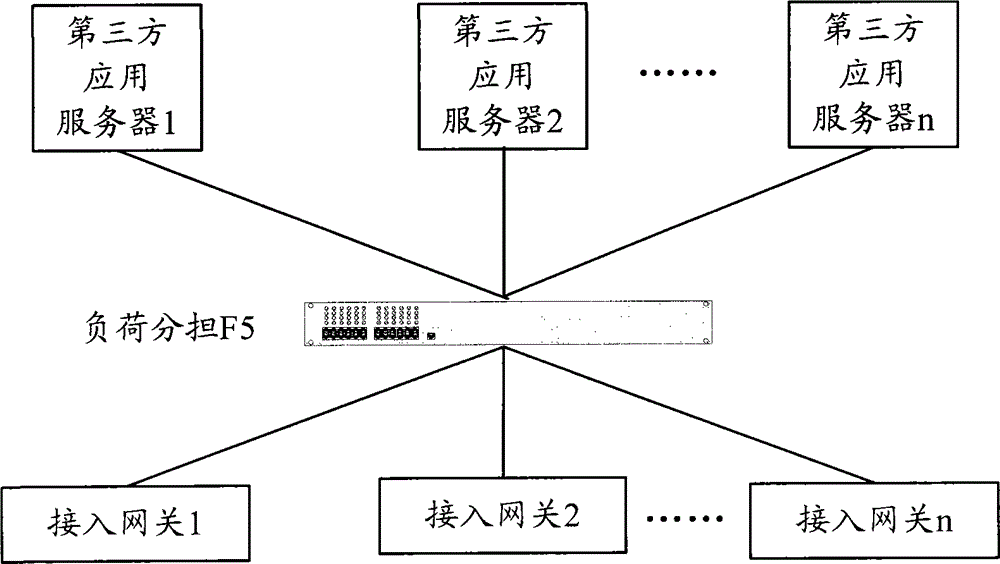

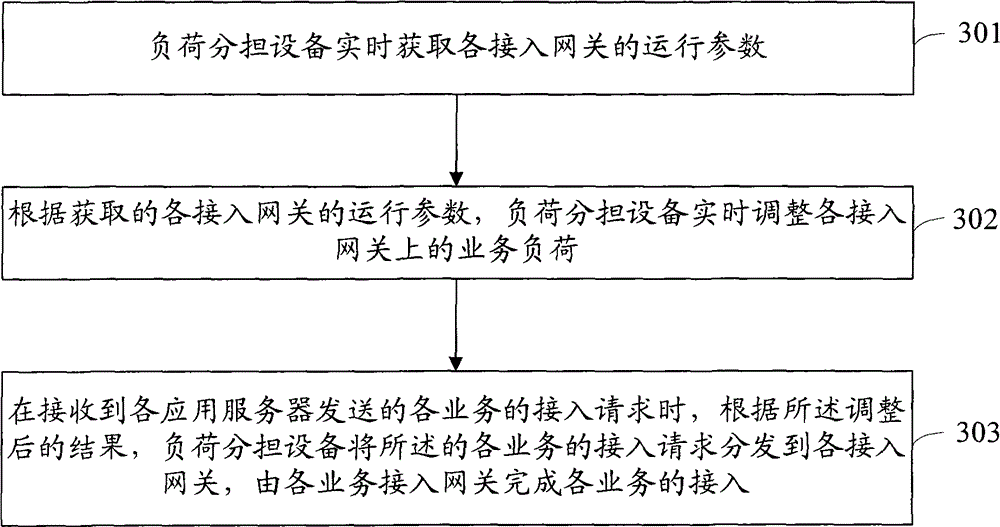

Method, device and system for realizing service access of access gateways

A method for implementing service access to access gateways is disclosed by the present invention, which mainly includes: obtaining the running parameters of each access gateway in real-time by a load sharing device, and then according to the running parameters, adjusting the service load of each access gateway by means of dynamic adjusting load sharing policies; when receiving access requests of each service sent by each application server, according to the adjusted result, distributing the access requests of each service to each access gateway; accomplishing the access of each service by each access gateway. A load sharing device and system for implementing the service access to the access gateways are also disclosed by the present invention. The present invention enables dynamic loading and unloading the service access to each access gateway; effectively solves the problem of running load imbalance of the access gateways and difficulties of implementing system capacity expansion etc, which exist in current access gateway systems; improves the utilization rate of the access gateways; reduces the cost of operators; and simultaneously, also lightens the harness of system upgrade and maintenance.

Owner:ZTE CORP

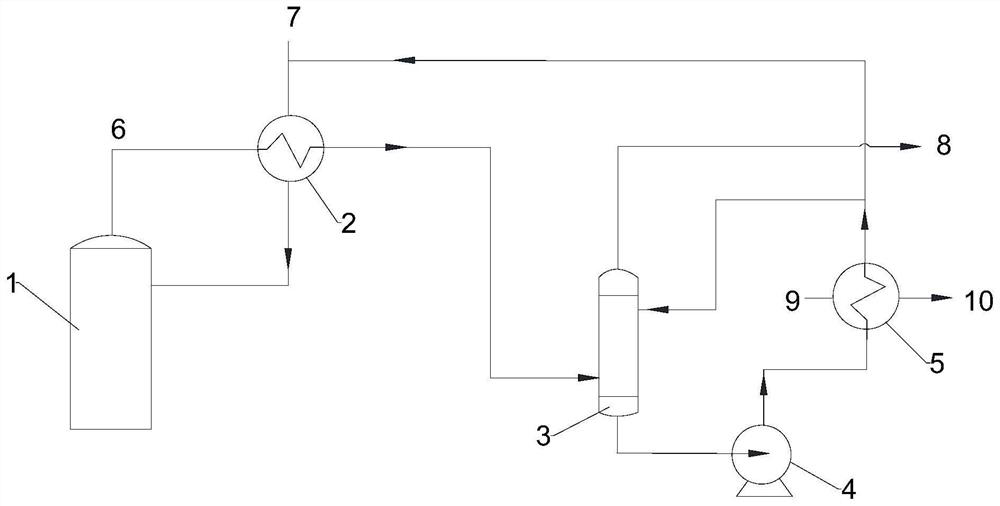

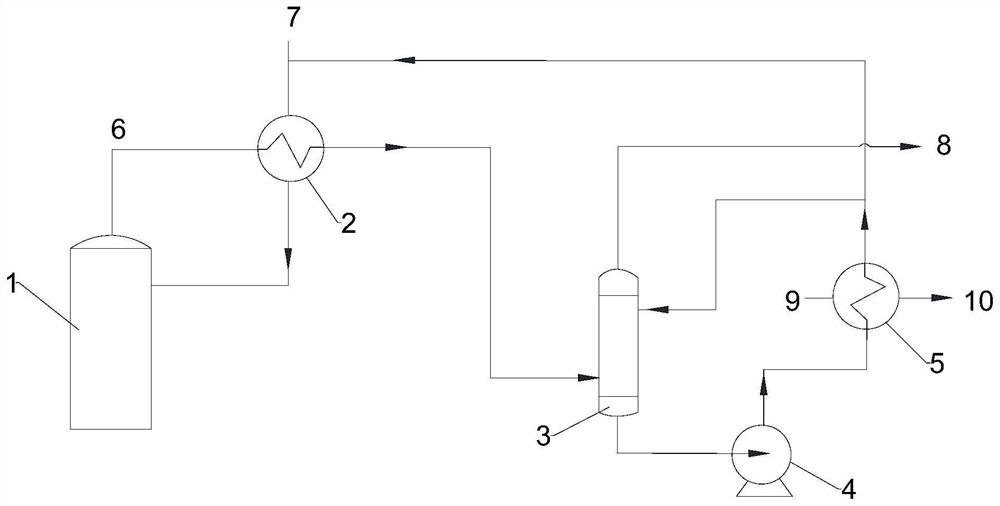

A method and device for slowing down the corrosion of the condensate stripping tower top reflux system

ActiveCN111760320BSolve or slow down corrosion problemsReduce inspection and maintenance costsVapor condensationSteam distillationThermodynamicsProcess engineering

The application provides a method and device for slowing down the corrosion of the top reflux system of a condensate stripper, which relates to the technical fields of coal chemical industry and petroleum processing. The device includes a condensate stripping tower and a spray tower, and the non-condensable gas output from the top of the condensate stripping tower is cooled by using the spray tower. The above-mentioned device is simple in structure and easy to operate. Using the spray tower as the non-condensable gas cooling system to replace the traditional tower top condenser can effectively solve or slow down the local serious ammonia substances in the tower top reflux system in the existing condensate stripping process. Corrosion Corrosion problems, reduce inspection and maintenance costs Avoid or reduce unplanned shutdowns caused by leakage problems, reduce maintenance costs, and ensure the safe, stable, and long-term operation of the entire stripping system.

Owner:CHINA PETROLEUM & CHEM CORP +1

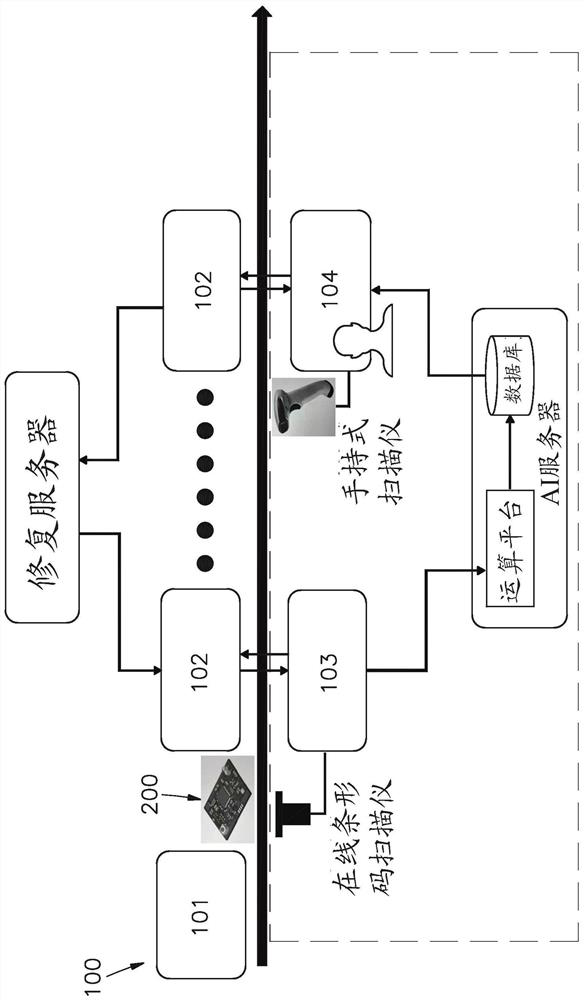

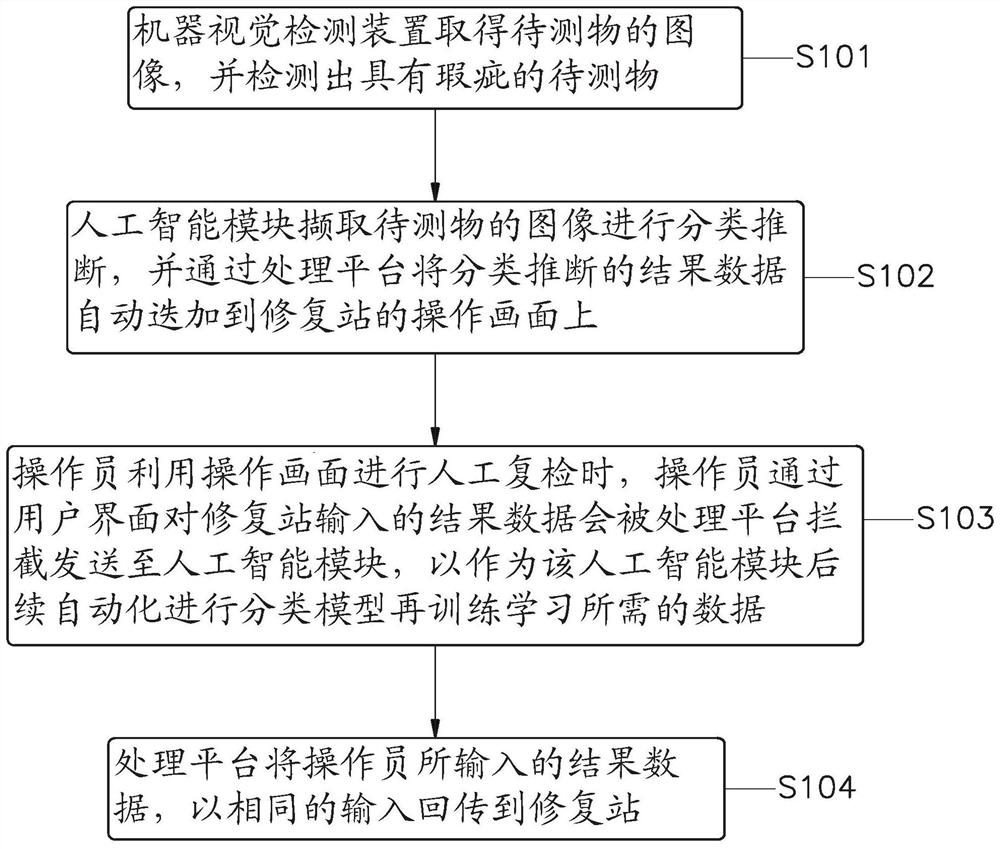

Automatic detection system and operation method thereof

PendingCN114820412AShorten learning curveIncrease productionImage enhancementImage analysisEngineeringAlgorithm

The invention discloses an automatic detection system and an operation method of the automatic detection system. The automatic detection system comprises a machine vision detection device, a repair station connected with the machine vision detection device, an artificial intelligence module and a processing platform connected with the repair station and the artificial intelligence module. The machine vision detection device can obtain an image of a to-be-detected object and display the image through an operation picture of the restoration station, the artificial intelligence module captures the image of the to-be-detected object for classified inference, and the processing platform is used for automatically superposing result data of image classified inference of the to-be-detected object onto the operation picture of the restoration station. And intercepting manual re-judgment result data input by an operator to the repair station through the user interface, and then sending the result data to the artificial intelligence module to serve as data for subsequent automatic classification model re-training learning.

Owner:ADLINK TECH INC

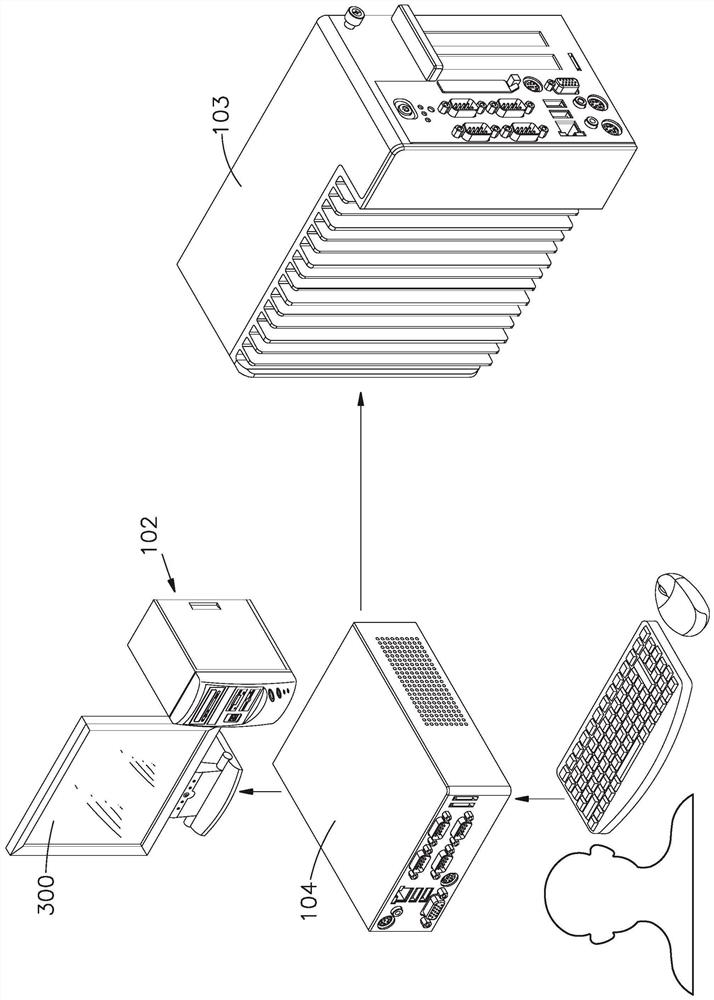

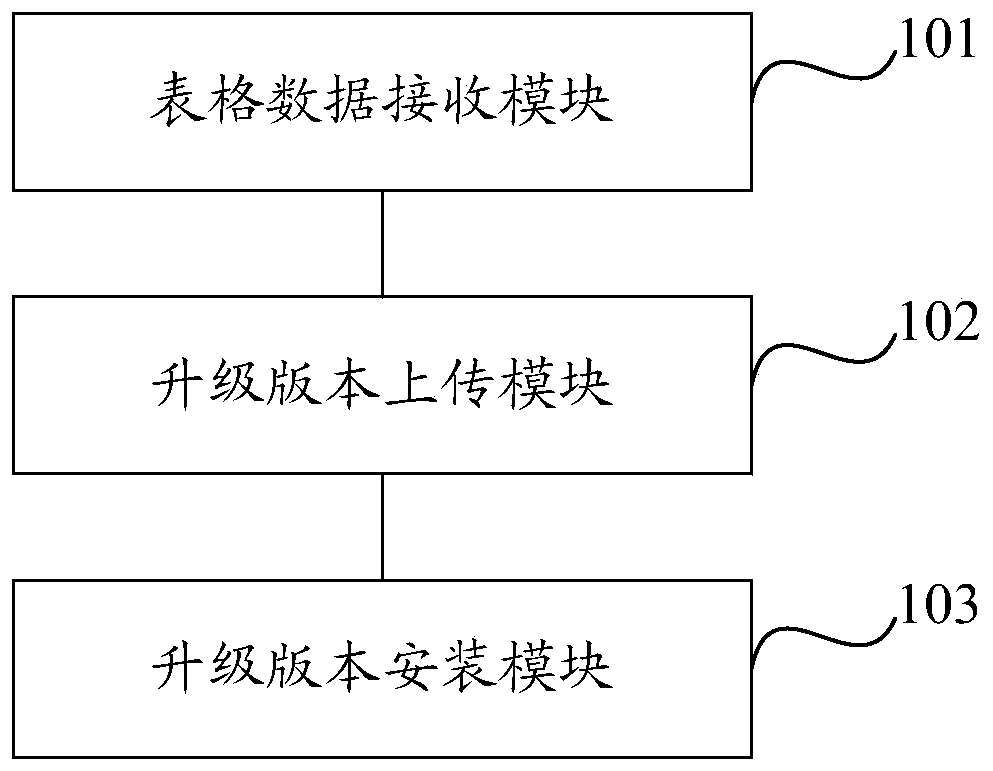

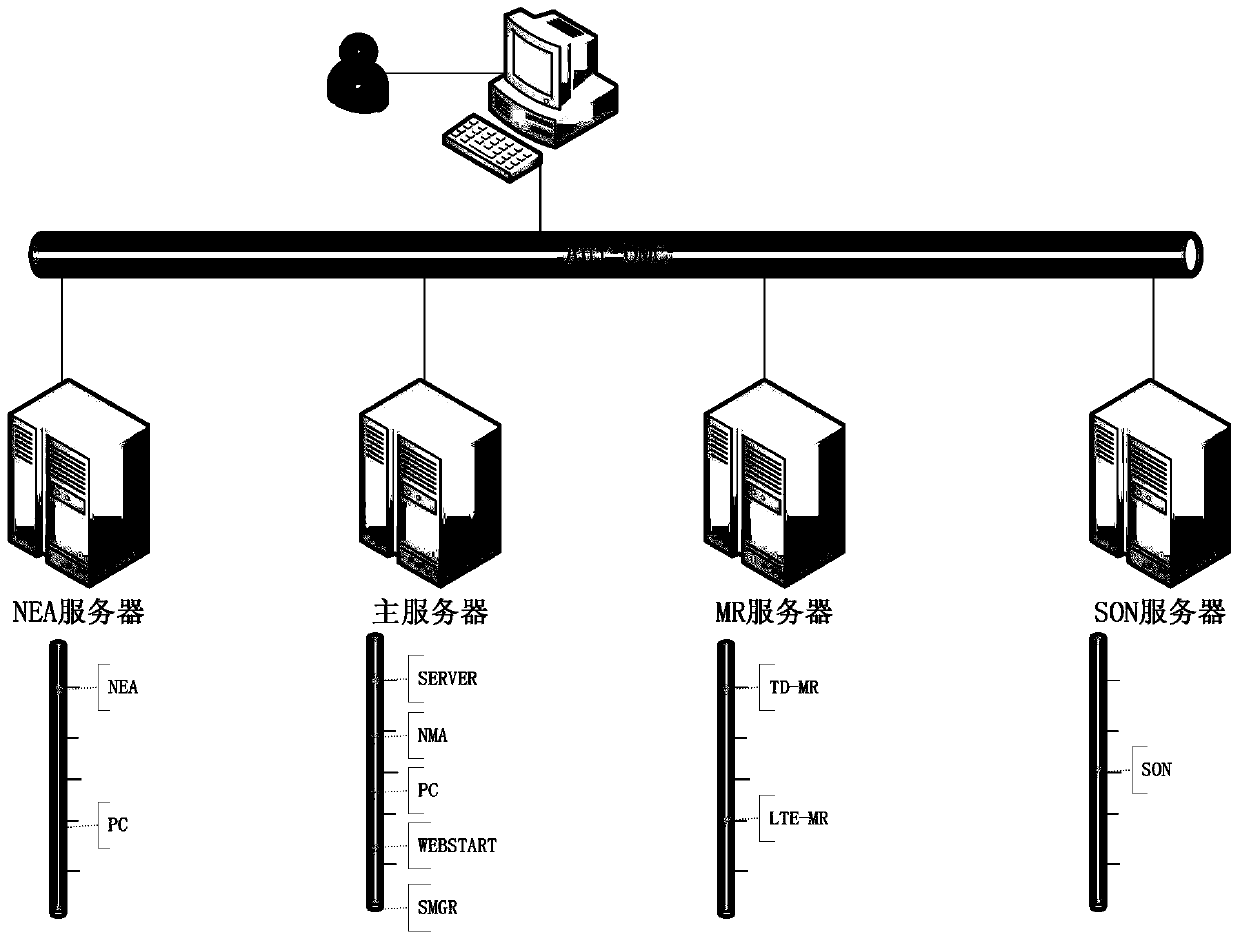

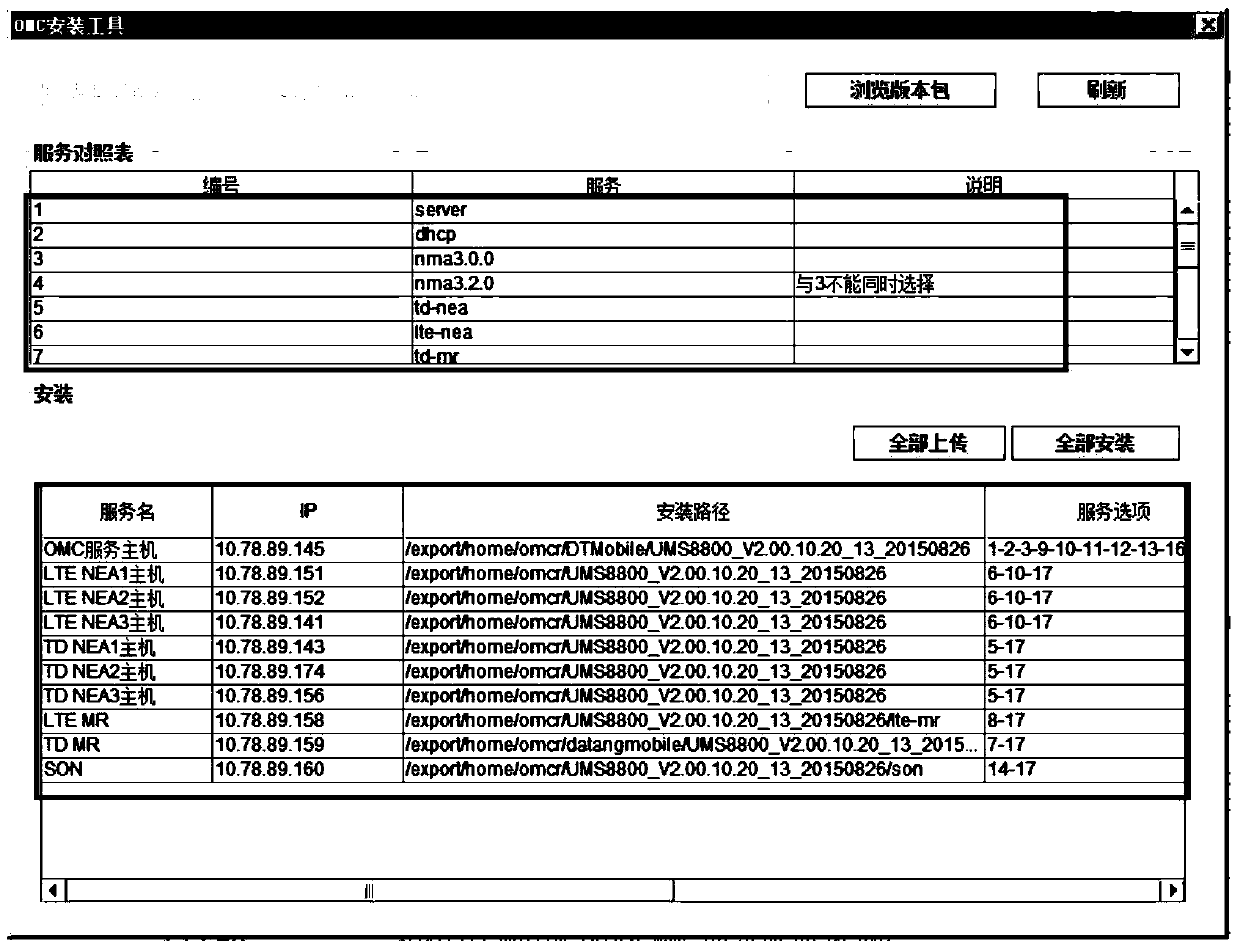

A method and device for upgrading an operation and maintenance center system

ActiveCN107135089BImprove upgrade success rateWarranty completedData switching networksWireless communicationNetwork managementMobile Web

The embodiment of the invention provides a method and a device for upgrading an operation maintenance center (OMC). The device comprises a table data receiving module, an upgrade version uploading module and an upgrade version installing module, wherein the table data receiving module is used for displaying a table needing to be filled in to a user, and receiving table data input in the table by the user; the table data at least include server parameters included in the OMC and service identifiers needing to be installed for the service parameters; the upgrade version uploading module is used for acquiring upgrade version data corresponding to the service identifiers, and uploading the upgrade version data to servers corresponding to the server parameters; and the upgrade version installing module is used for controlling corresponding servers to install the upgrade version data when completion of uploading of the upgrade version data is detected. Through adoption of the method and the device, the whole version upgrade process can be controlled remotely; the network management version upgrade success rate is increased; and the influence of version upgrading on mobile network maintenance is lowered.

Owner:DATANG MOBILE COMM EQUIP CO LTD

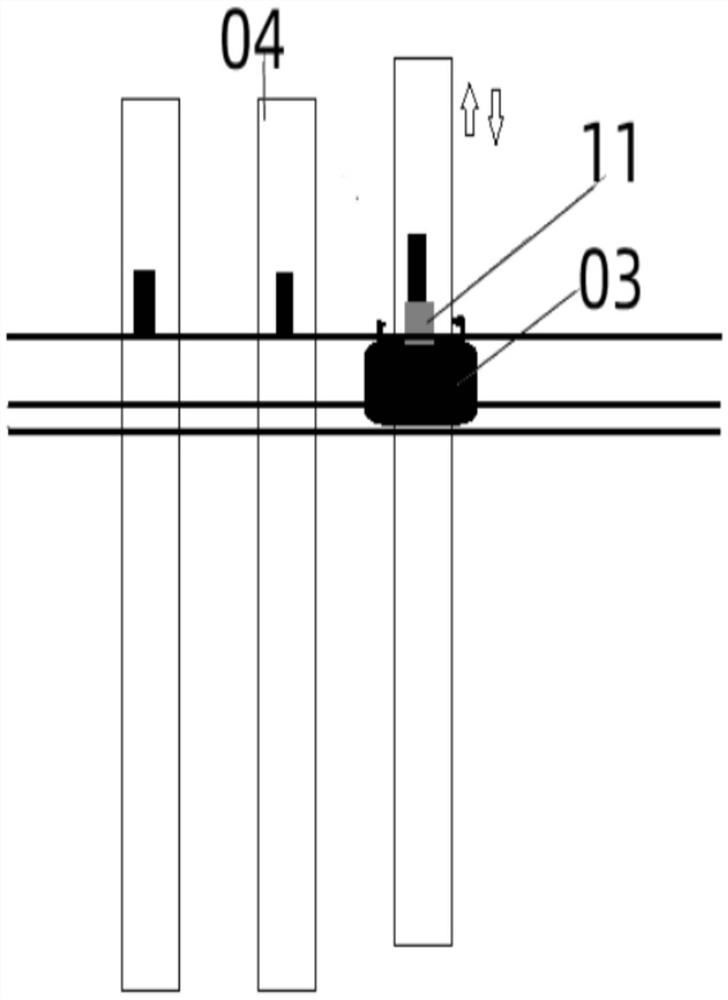

Plate filter press

PendingCN112206556AReduce work efficiencyShorten the life cycleFiltration separationPhysicsEngineering

The invention discloses a plate filter press which comprises a thrust plate, a filter pressing plate (04), a plate taking trolley (03) and a filter cloth which is deformed after being filled with fluid with pressure, when the plate filter press enters an unloading state, a fluid temporary storage cavity (06) is expanded, so that the filter cloth is deformed, and the contact area of the filter cloth and a solid material subjected to filter pressing is gradually reduced, falling and separation of solid matters from the filter cloth under the action of gravity after filter pressing is finished are facilitated, fluid with certain pressure escapes from pores of the filter cloth, an external force is applied to the filter-pressed materials, and falling and separation of the solid materials and the filter cloth after filter pressing are better facilitated. Fluid with pressure escapes from pores of the filter cloth, so that small particles remained in the pores can be separated. After the discharging state is finished, the filter pressing plates (04) are overlapped, so that the effect of cleaning the pores of the filter cloth is achieved. According to the scheme provided by the invention,the labor consumption of the plate filter press in an unloading state is reduced, the filter cloth can be kept in a relatively good working state, and the frequency of disassembly, cleaning and replacement is reduced.

Owner:李文博

Liquid crystal module testing method and device for dp decoding and resolution automatic adjustment

ActiveCN103050073BShorten adjustment timeImprove test efficiencyStatic indicating devicesTest efficiencyCommunication interface

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

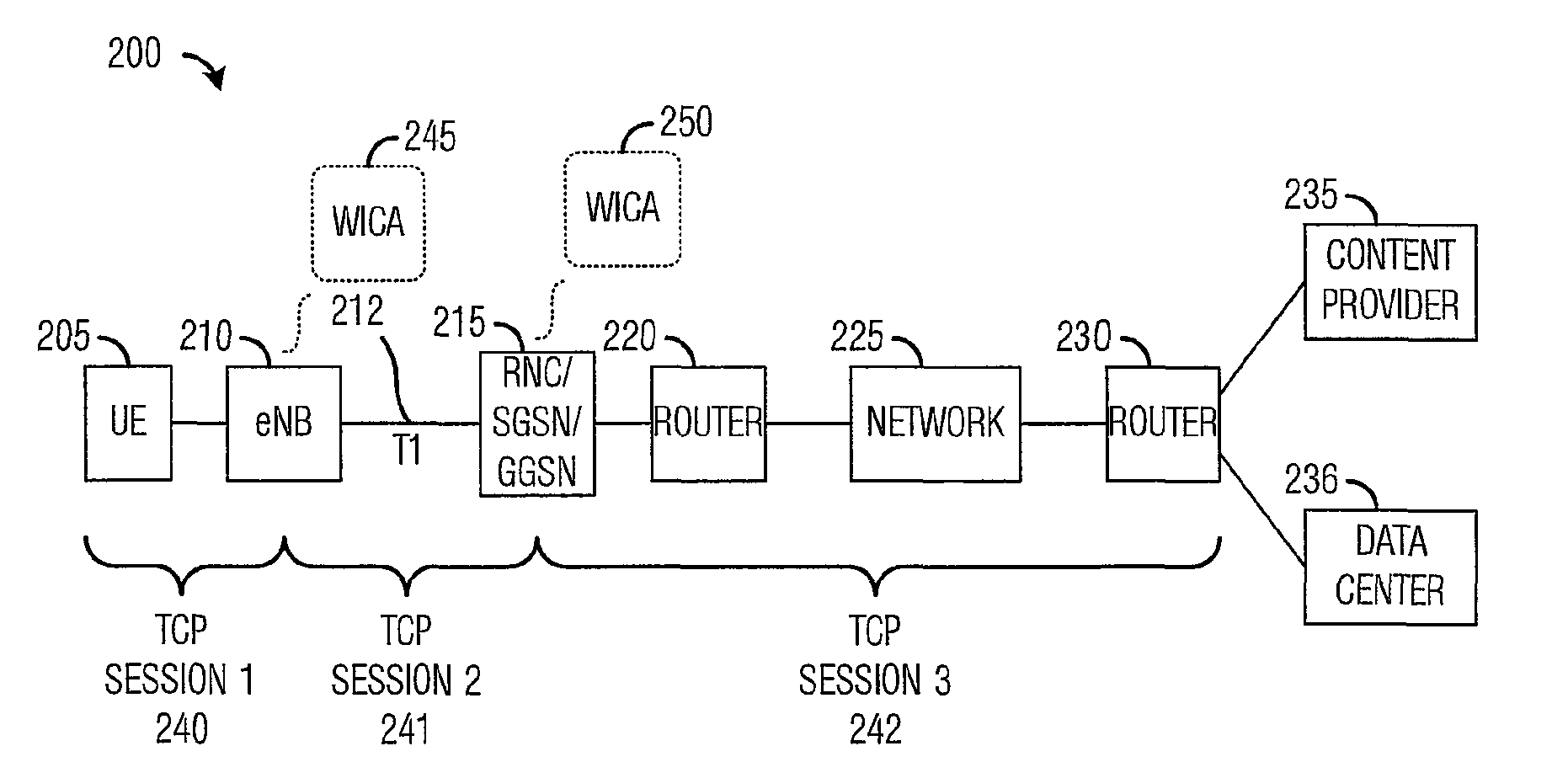

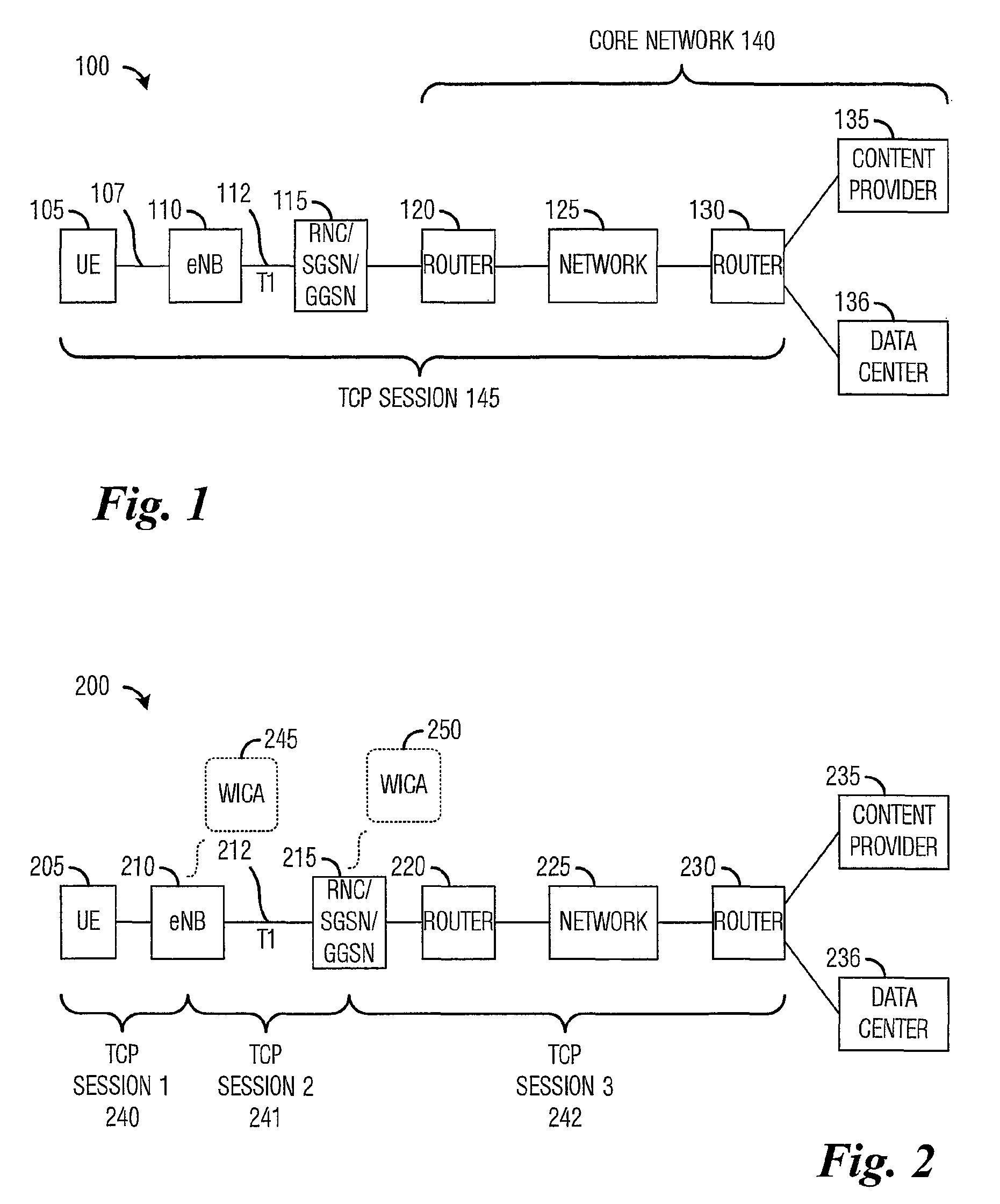

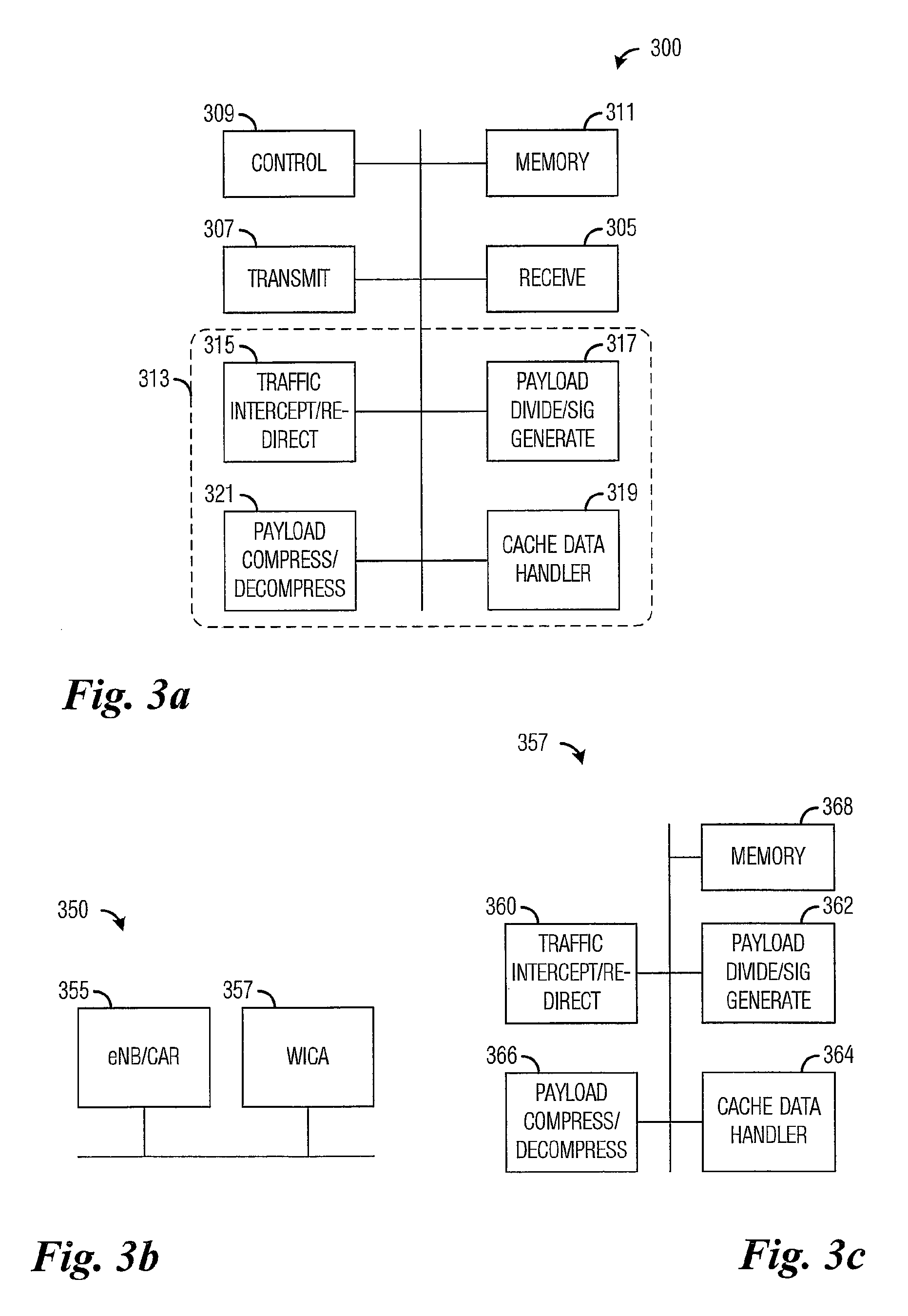

System and method for content and application acceleration in a wireless communications system

ActiveUS9420441B2Reduce bandwidth utilizationIncrease the number ofInformation formatContent conversionCommunications systemAcceleration Unit

A system and method for content and application acceleration in a wireless communications system are provided. A method for transmitting data includes receiving a block of data from a content provider, generating a signature from the block of data, and determining if the signature exists in a content cache. The content cache includes previously transmitted signatures and blocks of data associated with the previously transmitted signatures. The method also includes if the signature exists in the content cache, saving the signature but not the block of data in a buffer. The method further includes if the signature does not exist in the content cache, saving the block of data in the buffer. The method additionally includes transmitting contents of the buffer over a backhaul link.

Owner:FUTUREWEI TECH INC

Method and device for slowing down corrosion of reflux system at top of condensate stripping tower

ActiveCN111760320AIncrease the spray areaIncrease contact areaVapor condensationSteam distillationSpray towerChemistry

The invention provides a method and device for slowing down corrosion of a reflux system at the top of a condensate stripping tower, belonging to the technical field of the coal chemical industry andpetroleum processing. The device comprises a condensate stripping tower and a spray tower, wherein tower-top non-condensable gas output from the tower top of the condensate stripping tower is cooled by the spray tower. The device is simple in structure and convenient operation; the spray tower is used as a cooling system of the non-condensable gas to replace a traditional overhead condenser, so the problem of local severe corrosion of ammonia substances in an overhead reflux system in an existing condensate stripping process can be effectively solved or relieved, inspection and maintenance cost is reduced, non-planned shutdown caused by leakage is avoided or reduced, maintenance cost is reduced, and safe, stable and long-period operation of the whole stripping system is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

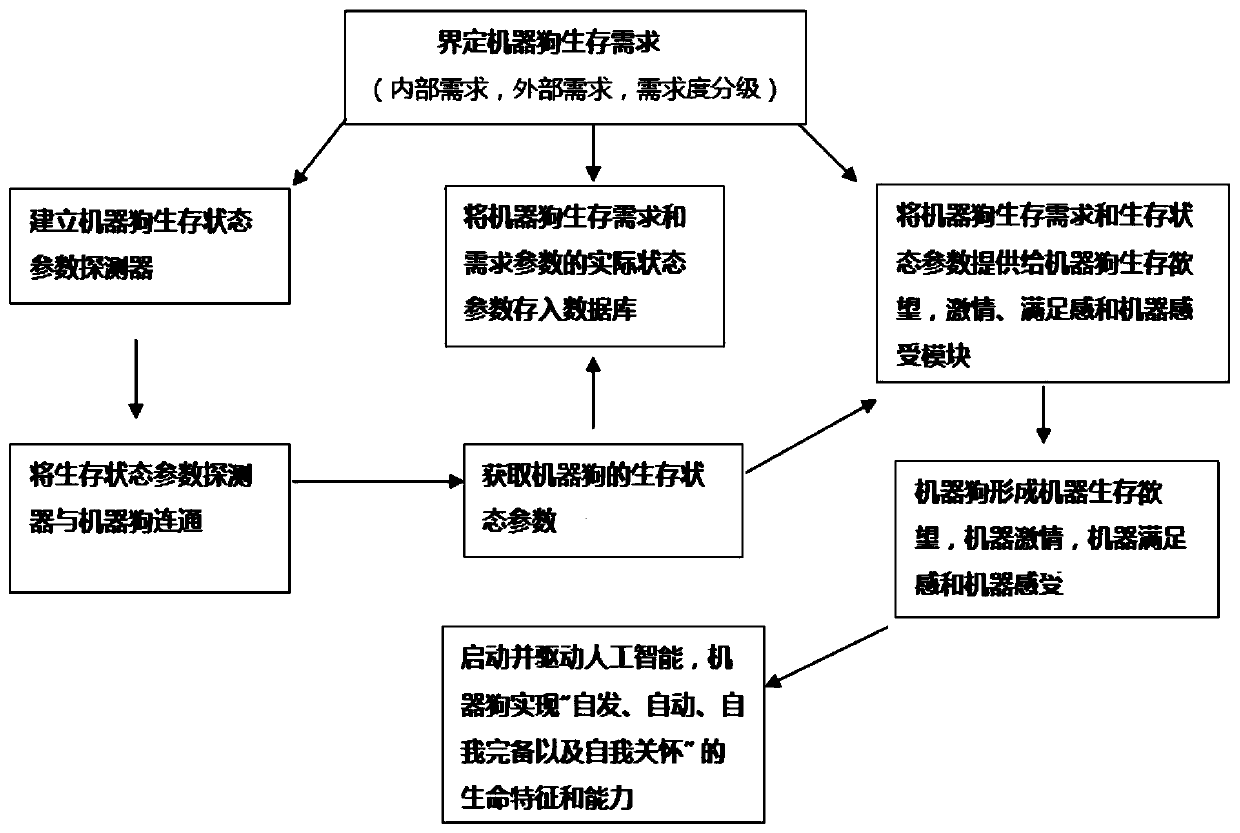

Method for enabling third-party machine system to obtain survivability emotion

PendingCN110263904AReduce design costReduce manufacturing costMeasurement devicesArtificial lifeThird partySurvivability

The invention discloses a method for enabling a third-party machine system to obtain a survivability emotion. The survivability emotion comprises machine survival desire, machine passion, machine satisfaction sense and a machine feeling. In butt joint with a third-party machine system, the third-party machine system is enabled to obtain a survivability emotion and drive artificial intelligence, and finally the survivability emotion of the machine becomes a key technology for enabling the machine to obtain 'spontaneous, automatic, self-complete and self-care 'vital signs and capabilities, so that the design and manufacturing cost of the machine is reduced, and the maintenance, repair, upgrade and scrap cost of the machine is reduced; target and power are provided for an artificial intelligence algorithm and data, the quality of a machine service person is improved, and the machine is endowed with fierce and love.

Owner:鄢华中

Movable comprehensive energy system for pasturing area

PendingCN113897271AGood environmental friendlinessImprove the ecological environment of pastoral areasBioreactor/fermenter combinationsBiological substance pretreatmentsPower gridGas separation

The invention discloses a movable comprehensive energy system for a pasturing area. An outlet of a fermentation device is sequentially connected with input ends of a gas separator, a micro gas turbine, a turbine and a motor, and an outlet of an air compressor is connected with an inlet of the micro gas turbine. Organic matter enters the fermentation device and is fermented to generate mixed gas, the mixed gas enters the gas separator, methane is filtered out through the gas separator, the separated methane enters the micro gas turbine, the air compressor pressurizes air, the high-pressure air enters the micro gas turbine, the micro gas turbine takes methane as fuel, the high-pressure air is used as combustion air for combustion, high-temperature flue gas is generated and pushes the turbine to do work and drive the motor to output electric energy. The system can be flexibly started and stopped independent of a traditional power grid, is convenient to arrange, facilitates migration along with herdsmen, and better meets living and production requirements of people in a pasturing area.

Owner:XIAN THERMAL POWER RES INST CO LTD

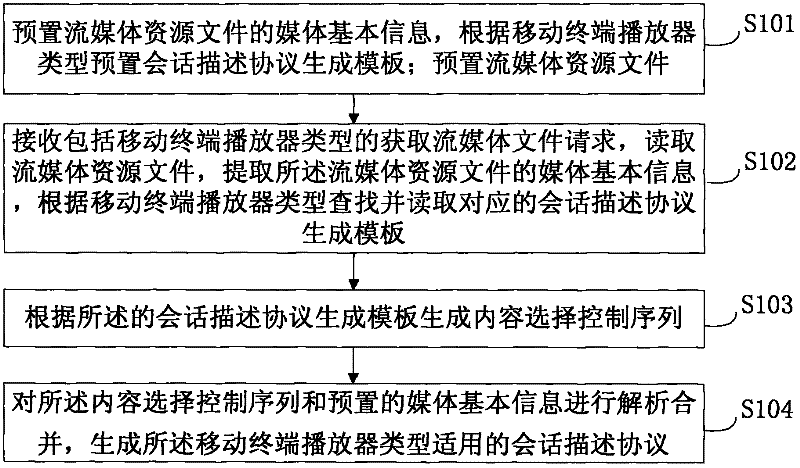

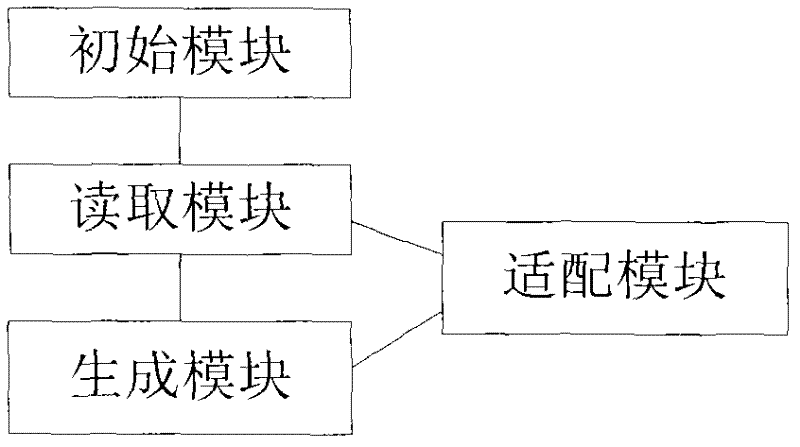

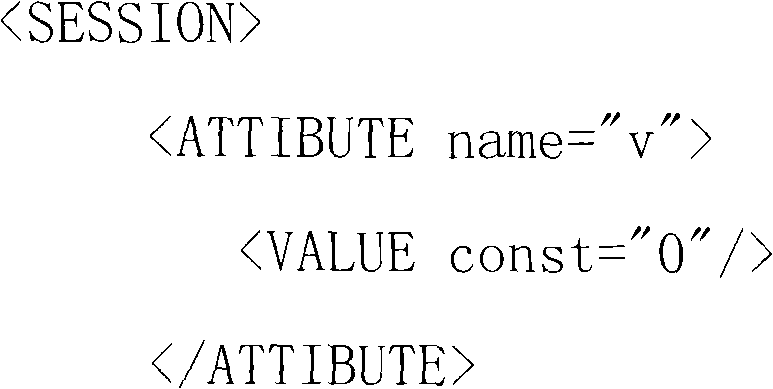

Method and system for adaptation of mobile terminal player SDP (Session Description Protocol)

InactiveCN102255891AEasy to adaptFit fastTransmissionSelective content distributionMedia serverComputer science

The invention discloses a method and system for the adaptation of a mobile terminal player SDP (Session Description Protocol). The method comprises the steps of: presetting basic media information of a stream media resource file, and presetting an SDP generation template according to the type of a mobile terminal player; generating a content selection control sequence by analyzing the SDP generation template; and finally generating an SDP adapting to the mobile terminal player by means of analysis and combination of the content selection control sequence and the preset basic media information. According to the invention, the efficiencies for product development and product launch are increased, the probabilities for modification and upgrading of the stream media server are reduced, and the convenient, shortcut and accurate adaptation of SDP is carried out on different types of mobile terminal players.

Owner:融创天下(上海)科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com