Plate filter press

A technology of plate filter press and filter plate, which is applied in the field of filter press, can solve the problems of reducing the working efficiency of plate filter press, increasing the frequency of disassembly and cleaning, and shortening the service life of filter cloth, so as to increase the frequency of disassembly and cleaning , Reduce the amount of labor, reduce the effect of disassembly and cleaning and replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

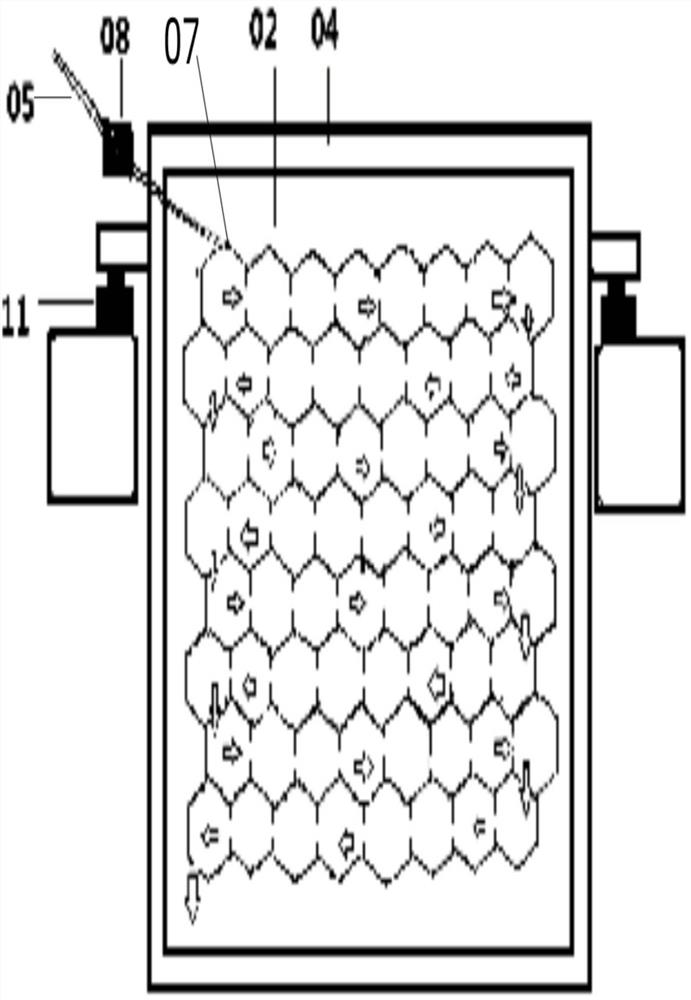

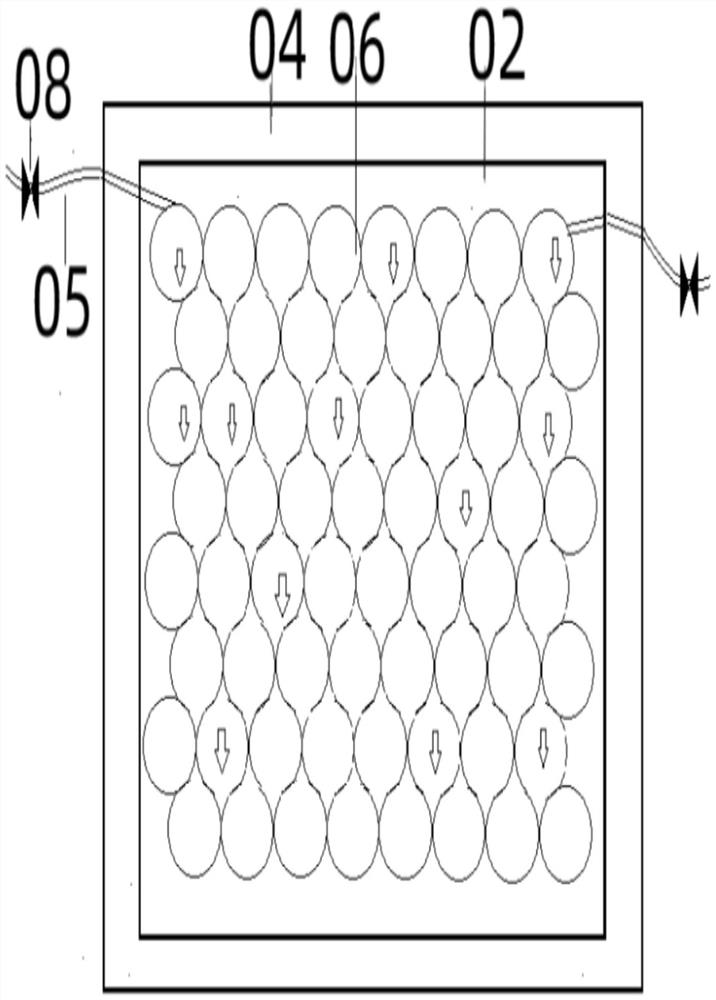

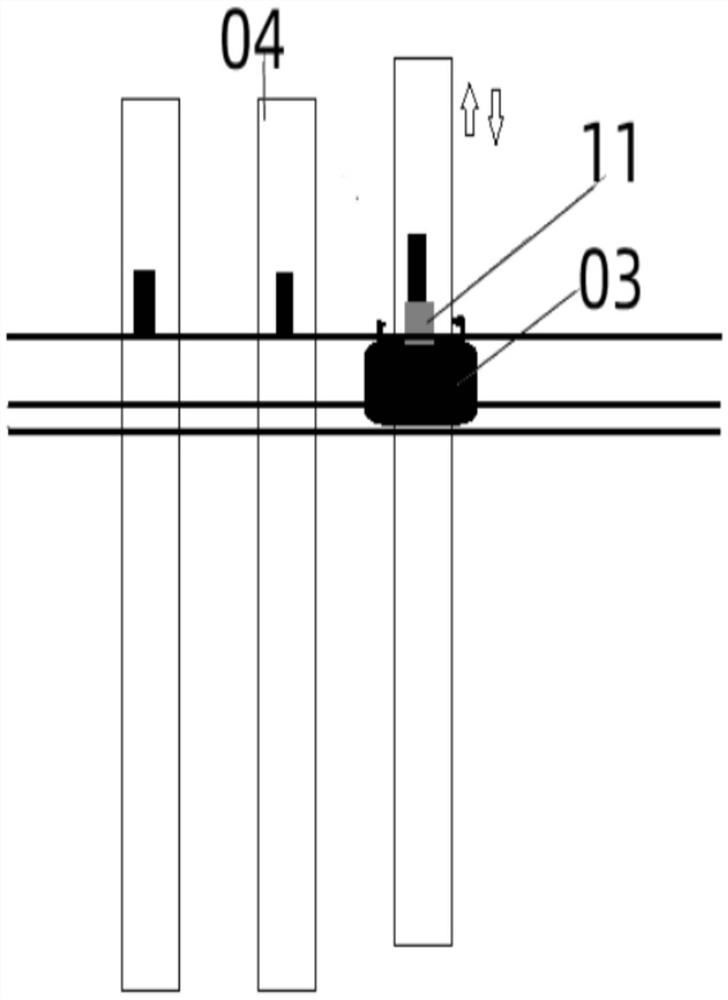

[0009] specific implementation

[0010] The fluid (01) described in the embodiment of the present application refers to a substance that can be filled into the fluid storage cavity (06) and can deform the fluid storage cavity (06), including but not limited to air, water and oily substances, usually compressed air.

[0011] After the filter press state of the plate filter press described in the embodiment of the present application ends, the unloading process starts, the filter press plate (04) is released, and the filter press plate (04) is pulled out piece by piece by the sampling trolley, adjacent When the filter press plate (04) is pulled apart by a certain distance, the device for controlling the fluid (01) entering the fluid storage chamber (06) is opened.

[0012] The device for controlling the fluid (01) entering the fluid storage chamber (06) includes and is not limited to the following two types. 1. The mechanical device has a part that controls opening and closing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com