Automatic detection system and operation method thereof

An automatic detection and operator technology, applied in the direction of optical testing flaws/defects, image analysis, instruments, etc., can solve the problems of increased re-inspection and waste of processing costs, large difference in proportion, high false alarm rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to achieve the above-mentioned purposes and effects, the technical means and structures adopted by the present invention are described in detail as follows with reference to the preferred embodiments of the present invention.

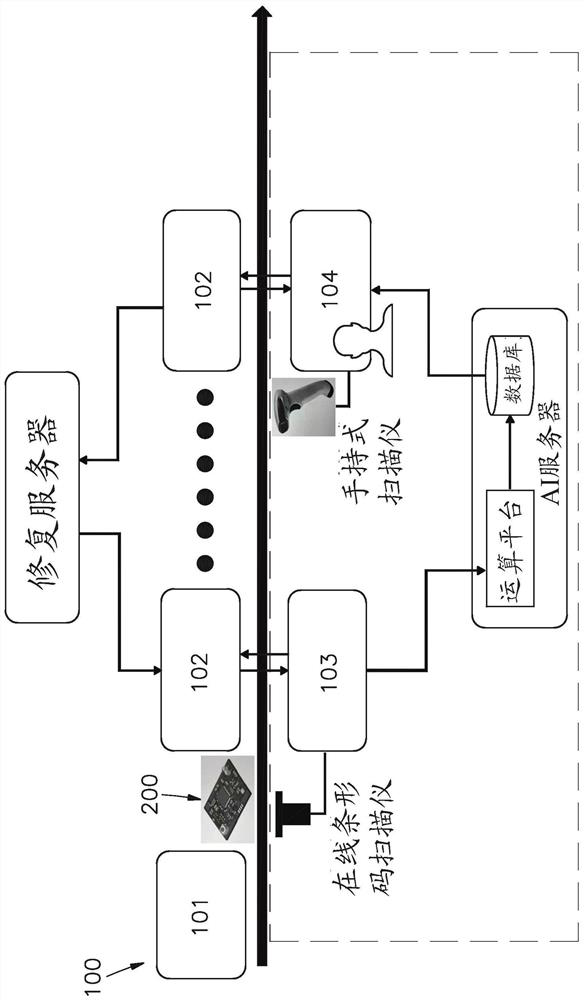

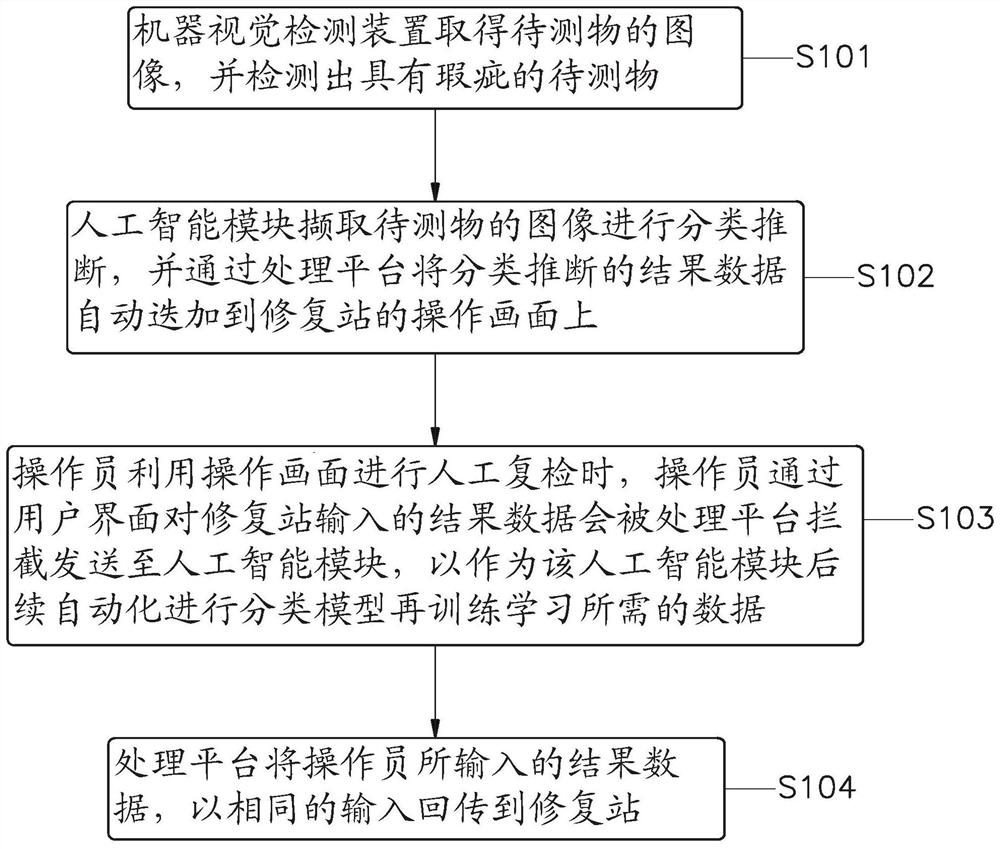

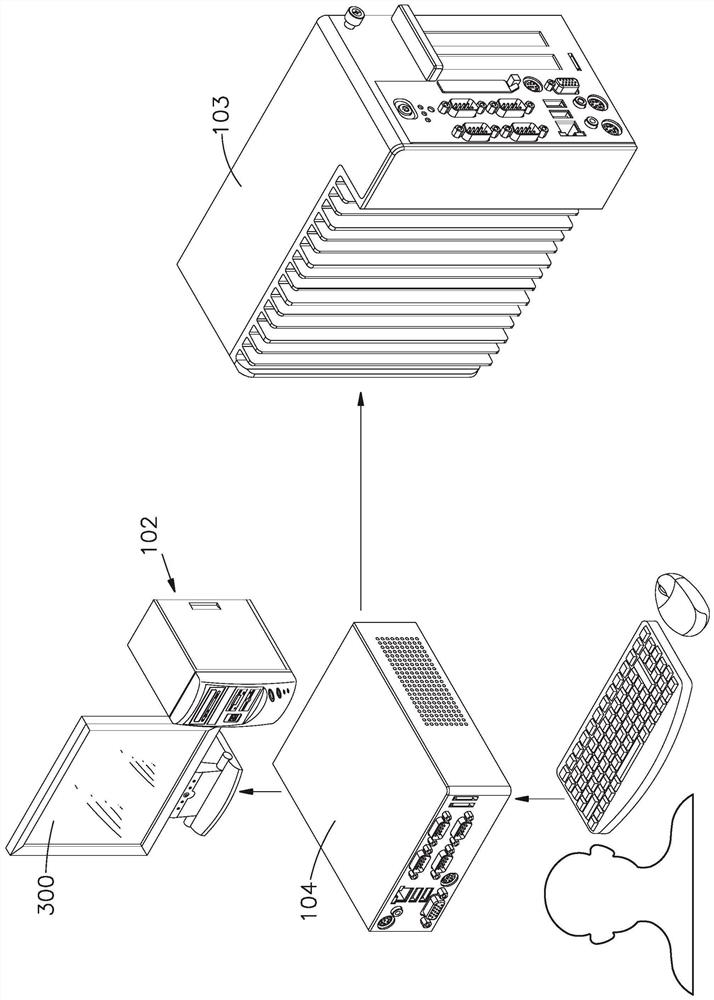

[0014] see Figure 1 to Figure 4 As shown, the schematic diagram of the structure of the automatic detection system of the present invention, the flow chart of the steps, the results of intercepting the operator's input and re-judgment to perform artificial intelligence training and returning the same input to the repair station are the schematic diagrams and the results of artificial intelligence classification and inference. The schematic diagram superimposed on the operation screen, it can be clearly seen from the figure that the automatic inspection system 100 of the present invention includes a machine vision inspection device 101 for taking images of the object to be tested 200 conveyed on the machine or on the conveyor belt and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com