A method and device for slowing down the corrosion of the condensate stripping tower top reflux system

A technology of condensate and stripper, which is applied in the fields of coal chemical industry and petroleum processing, can solve the problems of restricting the long-term stable operation of the device, corrosion and leakage of the tower top condenser, and threats to the safety production of the device, so as to reduce maintenance costs and ensure safety. , the effect of large spray area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

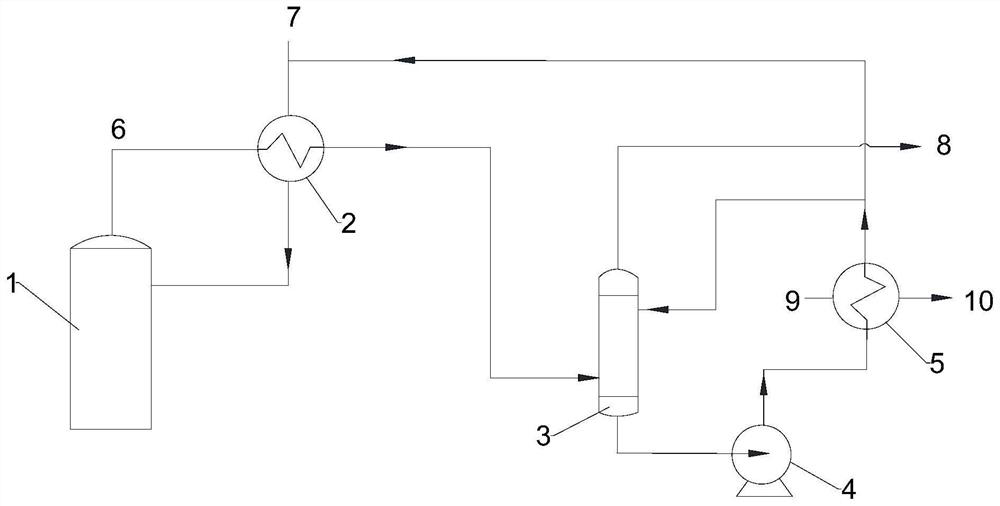

[0063] Please refer to figure 1 , the present embodiment provides a device for slowing down the corrosion of the condensate stripper overhead reflux system, which includes a condensate stripper 1 (single tower), a feed heat exchanger 2, a spray tower 3, a reflux pump 4 and Reflux heat exchanger 5, the inlet of feed heat exchanger 2 communicates with the tower top outlet of condensate stripping tower 1, the inlet of the tower bottom of spray tower 3 communicates with the outlet of feed heat exchanger 2, and reflux pump 4 The inlet of the pump is connected with the outlet at the bottom of the spray tower 3, the outlet of the reflux pump 4 is connected with the inlet of the reflux heat exchanger 5, and the outlet of the reflux heat exchanger 5 is respectively connected with the inlet of the top of the spray tower 3 and the condensed liquid vapor The entrance on the top of the tower 1 is connected. The recuperator 5 is also provided with a circulating cooling water inlet 9 and a ...

Embodiment 2

[0068] This embodiment provides a device for slowing down the corrosion of the condensate stripping tower overhead reflux system, which includes a condensate stripping tower (double tower), a feed heat exchanger, a spray tower, a reflux pump and a reflux heat exchanger, The inlet of the feed heat exchanger is connected with the top outlet of the condensate stripping tower, the inlet of the bottom of the spray tower is connected with the outlet of the feed heat exchanger, and the inlet of the reflux pump is connected with the outlet of the bottom of the spray tower The outlet of the reflux pump communicates with the inlet of the reflux heat exchanger, and the outlet of the reflux heat exchanger communicates with the inlet at the top of the spray tower and the inlet at the top of the condensate stripping tower respectively. The return heat exchanger is also provided with a circulating cooling water inlet and a circulating cooling water outlet.

[0069] Using the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com