System and method for monitoring mechanical components inside a wind turbine nacelle

A technology of mechanical parts and monitoring system, applied in the field of monitoring, can solve the problems of consuming a lot of human and material resources, high fan maintenance cost, increasing fan inspection and maintenance cost, etc., so as to improve the fan inspection and maintenance efficiency and reduce maintenance. cost and the effect of fault location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

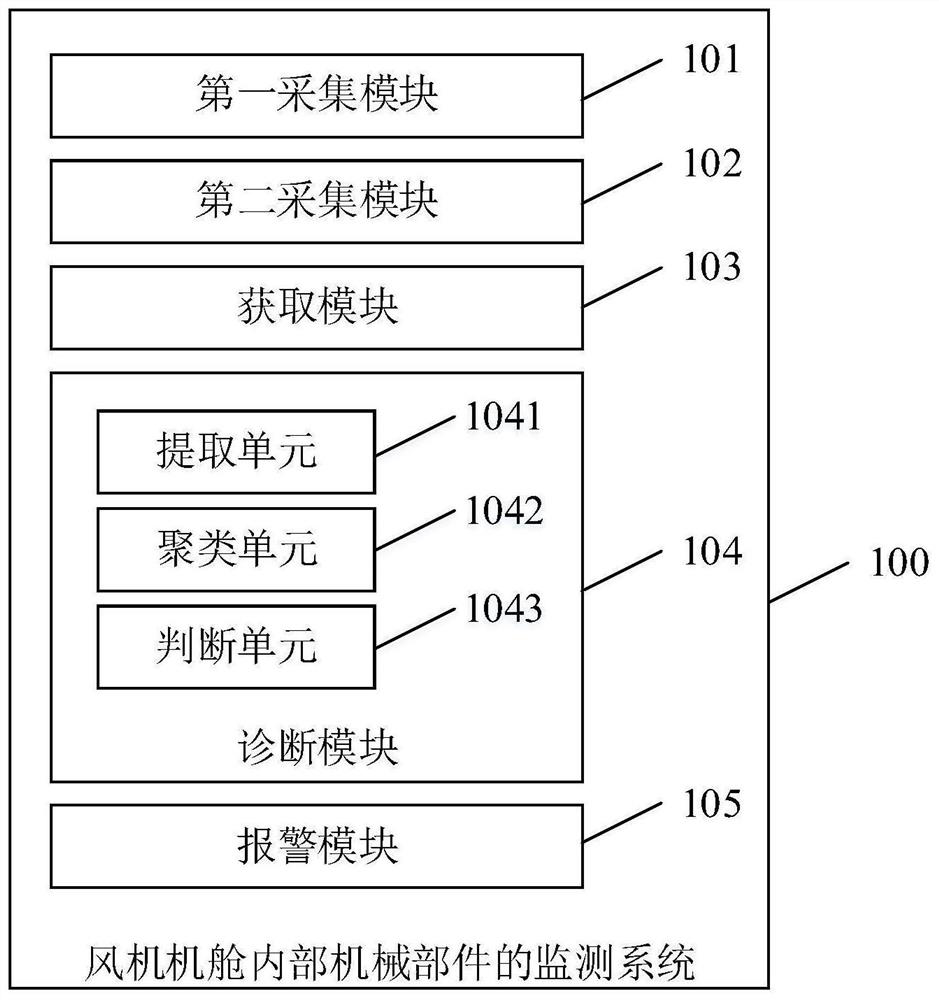

[0051] This embodiment provides a monitoring system for mechanical components inside the fan nacelle, figure 1 A schematic diagram of the modules of this embodiment is shown. refer to figure 1 , the monitoring system of the present embodiment includes:

[0052] The first collection module 101 is configured to collect a first audio signal at mechanical components inside the fan nacelle.

[0053] In this embodiment, the mechanical components may be mechanical components such as bearings, gears, etc. that need to be monitored in real time in the yaw system and pitch system inside the fan nacelle. Since the operation of the mechanical components will generate audio signals, the Therefore, the normal operation of the mechanical component can be shown as generating a stable audio signal, so it can be judged and analyzed whether the mechanical component fails based on the collected first audio signal of the mechanical component.

[0054] Specifically, in this embodiment, the first...

Embodiment 2

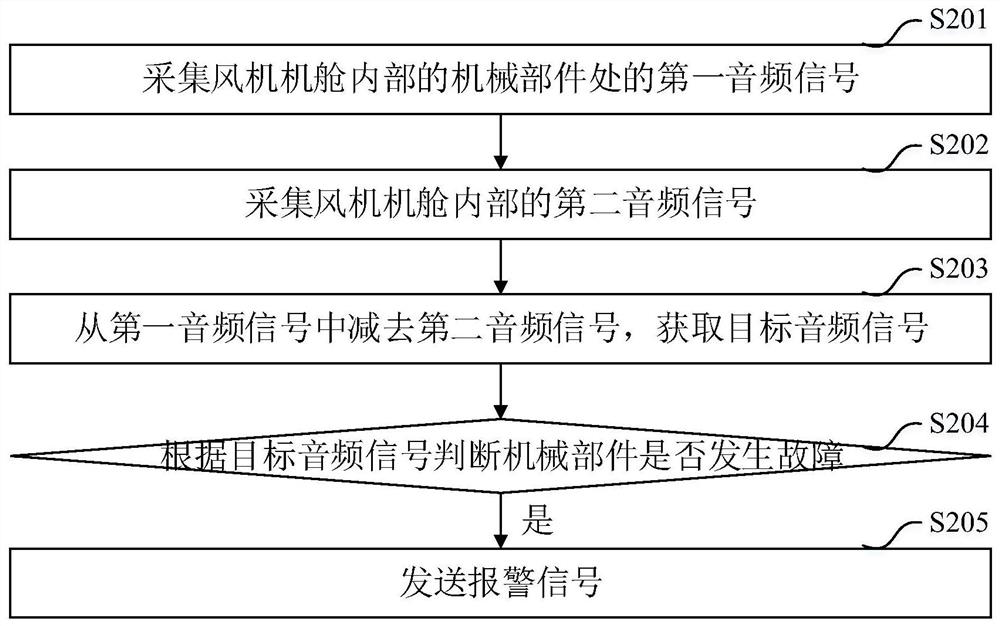

[0091] This embodiment provides a method for monitoring the mechanical components inside the fan nacelle, image 3 A flowchart of this embodiment is shown. refer to image 3 , the monitoring method of the present embodiment includes:

[0092] S201. Collect a first audio signal at a mechanical component inside a fan nacelle.

[0093] In this embodiment, the mechanical components may be mechanical components such as bearings, gears, etc. that need to be monitored in real time in the yaw system and pitch system inside the fan nacelle. Since the operation of the mechanical components will generate audio signals, the Therefore, the normal operation of the mechanical component can be shown as generating a stable audio signal, so it can be judged and analyzed whether the mechanical component fails based on the collected first audio signal of the mechanical component.

[0094] Specifically, in this embodiment, a directional acquisition module such as a directional microphone array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com