Return ash control device of circulating fluidized bed boiler return feeder and control method

A circulating fluidized bed and control device technology, which is applied in the boiler field, can solve problems such as poor boiler operation stability, environmental protection facility processing capacity, inability to accurately control the return ash of the feeder, and increased return volume of the feeder, etc. Achieve the effect of eliminating heat pollution, occupying a small area, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are presented to illustrate certain embodiments of the invention and should not be construed as limiting the scope of the invention. The content disclosed in the present invention can be improved simultaneously from materials, methods and reaction conditions, and all these improvements should fall within the spirit and scope of the present invention.

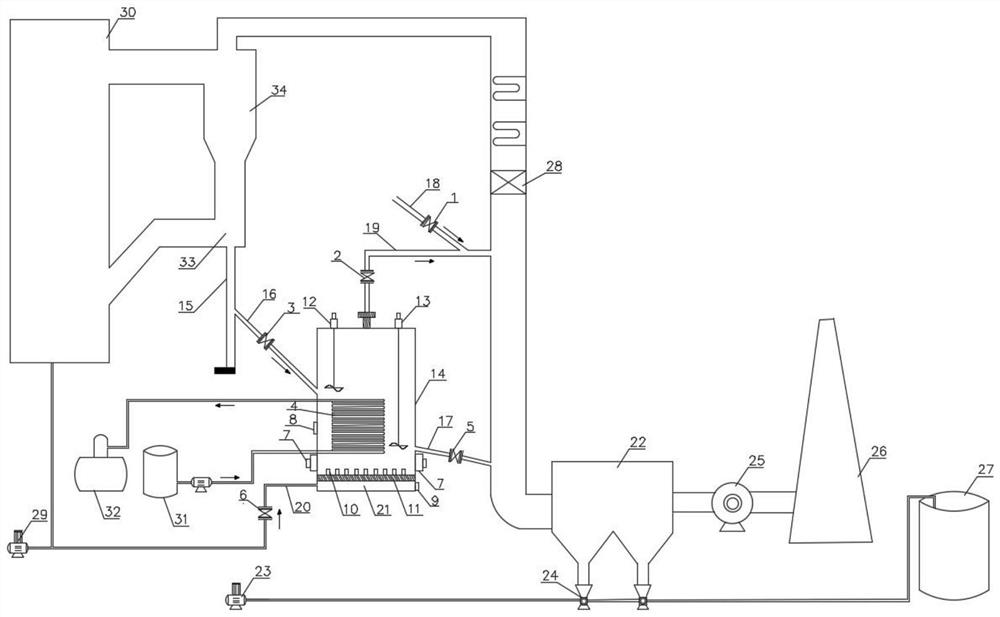

[0032] Such as figure 1 As shown, a circulating fluidized bed boiler feeder return ash control device includes a return ash storage tank 14, and one side of the return ash storage tank 14 passes through a feed pipe 16 and a feeder ash discharge pipe. 15, the other side of the return ash storage tank 14 communicates with the bottom flue of the air preheater 28 through the ash discharge pipe 17, and the top of the return ash storage tank 14 communicates with the air preheater through the exhaust pipe 19 The flue at the bottom of 28 is connected, and the flue at the bottom of the air preheater 28 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com