An economical HIC-resistant x90 pipeline steel plate and its manufacturing method

An economical, steel plate technology, applied in the economical anti-HICX90 pipeline steel plate and its manufacturing field, can solve the problems of X90 steel grade anti-HIC steel plate or steel pipe not being reported, achieve excellent anti-HIC performance, excellent low temperature toughness, reduce The effect of small erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

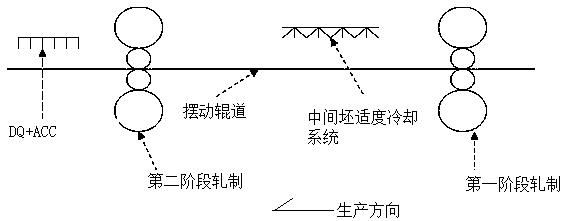

Method used

Image

Examples

Embodiment 1

[0030] The thickness of the HIC-resistant X90 pipeline steel plate in this embodiment is 20 mm, and its chemical composition is calculated by mass percentage: C: 0.06%, Mn: 1.70%, Si: 0.15%, S: 0.0005%, P: 0.01%, Nb : 0.055%, Ti: 0.018%, V: ≤ 0.05%, Al: 0.030%, Mo+Cu+Ni+Cr≤ 0.6%, N≤ 0.010%, O: ≤ 0.006%, Ca: 0.0008%, and the balance is Fe and unavoidable impurity elements.

[0031] First, the smelting raw materials are pretreated by KR molten iron, converter smelting, LF refining, and RH vacuum refining. During the refining process, the S content in molten steel is controlled to be ≤0.0005%, and then fed to the Ca-Si line to control the Ca / S content ratio in molten steel. 1.0 to 2.0, and then continuously cast continuous casting slabs that meet the chemical composition requirements and have a thickness of not less than 350mm. The continuous casting slab is reheated to 1280-1310°C, and the heat preservation is not less than 8 hours; two-stage rolling is carried out after being ...

Embodiment 2

[0034] The thickness of the HIC-resistant X90 pipeline steel plate of this embodiment is 19.6mm, and its chemical composition is calculated by mass percentage: C: 0.04%, Mn: 1.90%, Si: 0.28%, S: 0.0005%, P: 0.01%, Nb: 0.058%, Ti: 0.018%, V: ≤0.05%, Al: 0.030%, Mo+Cu+Ni+Cr≤ 0.9%, N≤ 0.010%, O: ≤ 0.006%, Ca: 0.0008%, balance It is Fe and inevitable impurity elements.

[0035] First, the smelting raw materials are pretreated by KR molten iron, converter smelting, LF refining, and RH vacuum refining. During the refining process, the S content in molten steel is controlled to be ≤0.0005%, and then fed to the Ca-Si line to control the Ca / S content ratio in molten steel. 1.0 to 2.0, and then continuously cast a continuous casting slab that meets the chemical composition requirements and has a thickness of 300mm. 1300°C, heat preservation for 8 hours; the total compression ratio is 15.3, and two-stage rolling is carried out after being released from the furnace: the first stage is ro...

Embodiment 3

[0038] The thickness of the HIC-resistant X90 pipeline steel plate in this embodiment is 20 mm, and its chemical composition is calculated by mass percentage: C: 0.02%, Mn: 1.85%, Si: 0.35%, S: 0.0005%, P: 0.01%, Nb : 0.058%, Ti: 0.018%, V: ≤ 0.05%, Al: 0.030%, Mo+Cu+Ni+Cr≤ 0.9%, N≤ 0.010%, O: ≤ 0.006%, Ca: 0.0008%, the balance is Fe and unavoidable impurity elements.

[0039] First, the smelting raw materials are pretreated by KR molten iron, converter smelting, LF refining, and RH vacuum refining. During the refining process, the S content in molten steel is controlled to be ≤0.0005%, and then fed to the Ca-Si line to control the Ca / S content ratio in molten steel. 1.0 to 2.0, and then continuously cast a continuous casting slab that meets the chemical composition requirements and has a thickness of 370mm. 1300°C, heat preservation for 8 hours; the total compression ratio is 18.5, and two-stage rolling is carried out after being released from the furnace: the first stage is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com