Nbc nano-particle reinforced steel plate for X90 plastic pipes and manufacturing method of steel plate

A technology of nano-particles and steel plates, applied in the field of metal materials, can solve problems such as differences, achieve the effects of reducing production costs, excellent HIC resistance, and meeting safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

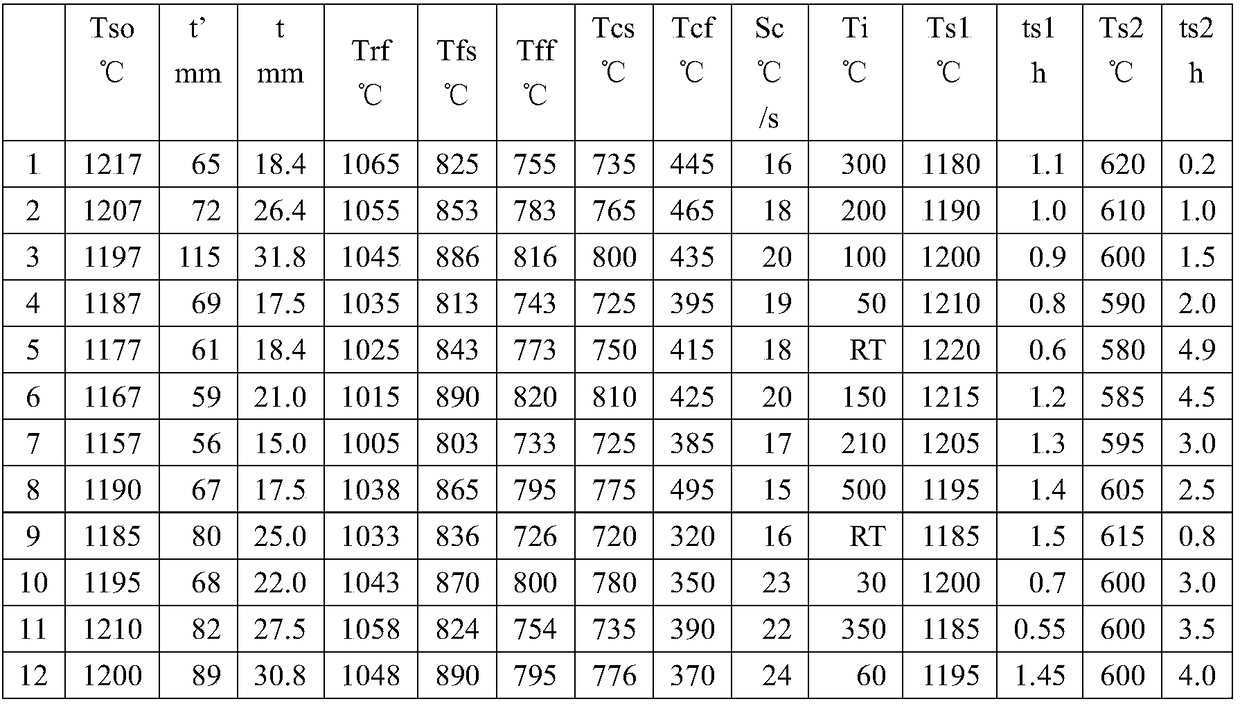

[0037] Below by embodiment the present invention will be further described.

[0038] According to the component ratio of the technical solution, the embodiment of the present invention includes material preparation→converter or electric furnace smelting→extra-furnace refining→casting→slab reheating→controlled rolling→controlled cooling→solution treatment→isothermal heat treatment→water cooling to room temperature,

[0039] (1) Slab reheating: After the steel slab is cleaned, it is reheated, and the temperature Tso of the steel slab is 1150-1220°C;

[0040] (2) Controlled rolling: rough rolling finishing temperature Trf ≥ 1000°C; intermediate billet thickness t' is 2.5t ~ 4.0t, t is the thickness of finished steel plate; finish rolling start temperature Tfs is 800 ~ 900°C, finishing The final rolling temperature Tff is 720-820°C;

[0041] (3) Controlled cooling: the starting cooling temperature Tcs is 720-800°C, the final cooling temperature Tcf is 300-500°C, and the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com