Solid gas protection welding wire used for welding crude oil carrier cargo oil tank boat deck

A gas-shielded welding wire and cargo technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of compositional design differences, etc., to achieve improved corrosion resistance, consistent corrosion resistance and pitting resistance Ability to improve the effect of anti-HIC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

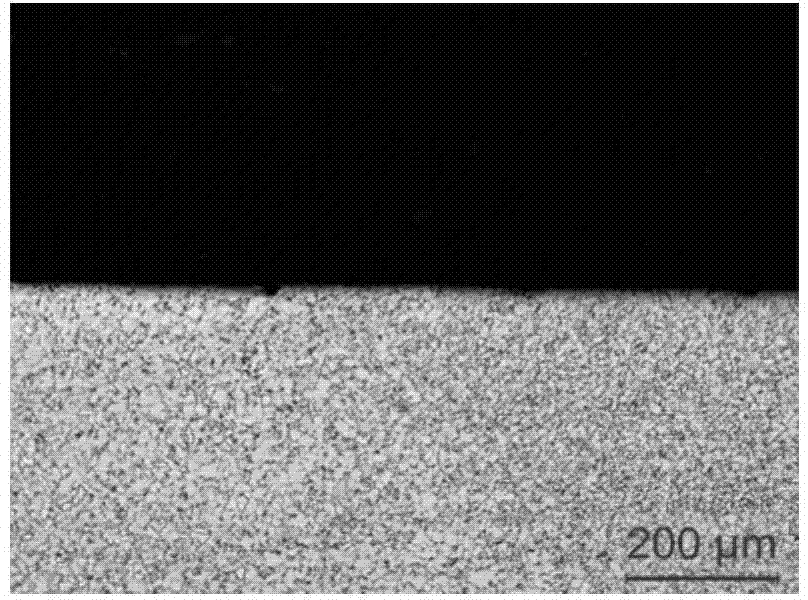

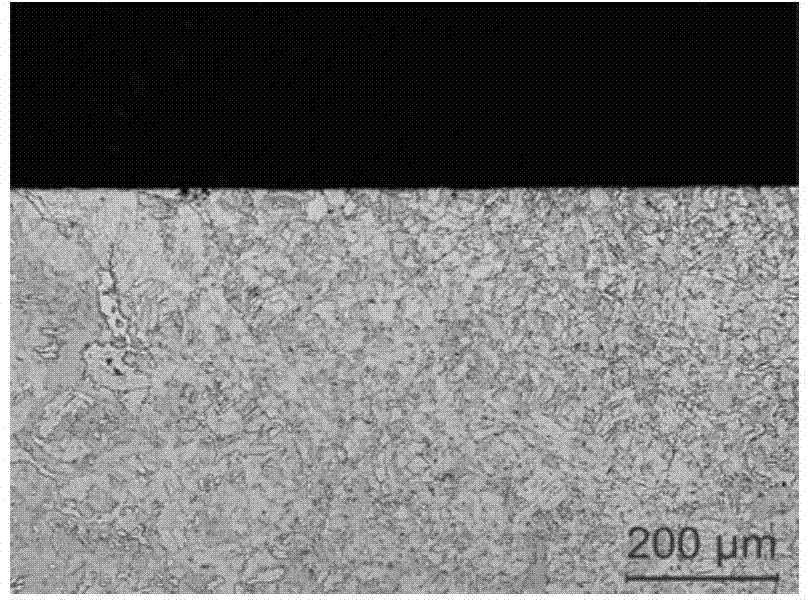

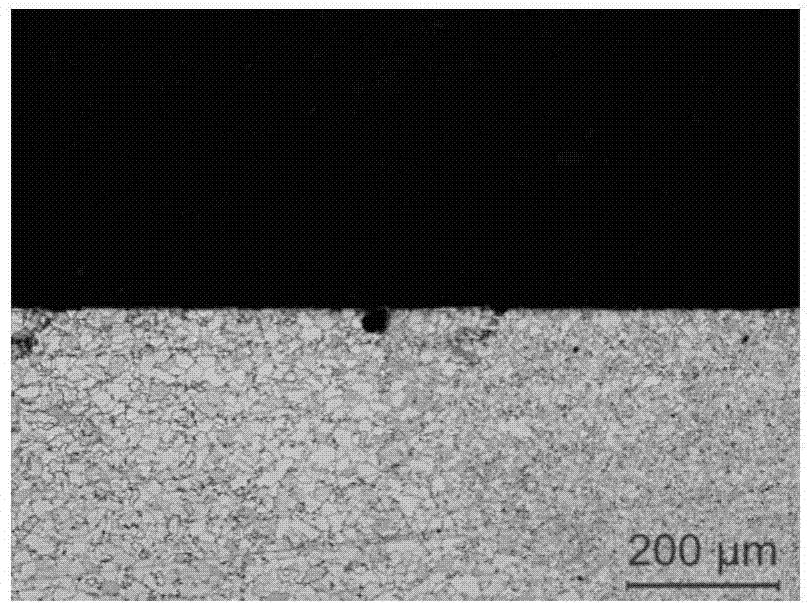

Image

Examples

Embodiment 1~5

[0032] Vacuum induction furnace is used for smelting, and the mass percentage distribution of chemical elements is controlled as shown in Table 1; the welding wire with a diameter of 1.2mm is drawn by conventional technology.

[0033] Table 1. The mass percent distribution ratio of the chemical elements of Examples 1 to 5

[0034] (wt%, the balance is Fe and other unavoidable impurities)

[0035] serial number

C

Si

mn

Ti

Mo

Cr

Al / t

Cu

Ni

Example 1

0.058

0.51

0.94

0.063

0.19

0.25

0.047

0.19

0.37

Example 2

0.041

0.41

0.91

0.021

0.21

0.31

0.071

0.25

0.47

Example 3

0.091

0.36

0.82

0.043

0.02

0.36

0.052

0.75

0.25

Example 4

0.028

0.58

0.99

0.075

0.46

0.28

0.096

0.30

0.75

Example 5

0.074

0.43

0.83

0.087

0.35

0.46

0.021

0.60

0.51 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rm | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com