TMCP delivery economical HIC-resistance pipeline steel plate X65MS and manufacturing method thereof

A manufacturing method and an economical technology, applied in the field of metallurgy, can solve the problems of high manufacturing cost of HIC-resistant pipeline steel and unstable HIC performance, and achieve the effects of good HIC-resistant performance, prolonging heating time, and increasing heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

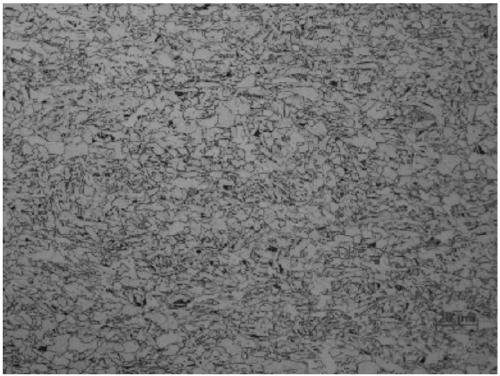

Image

Examples

Embodiment 1 and 2

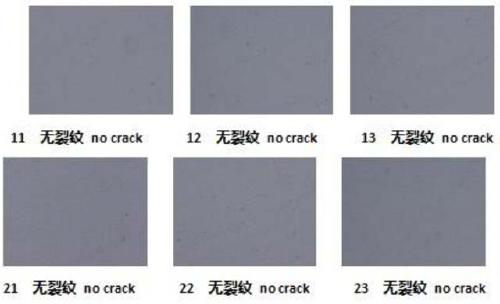

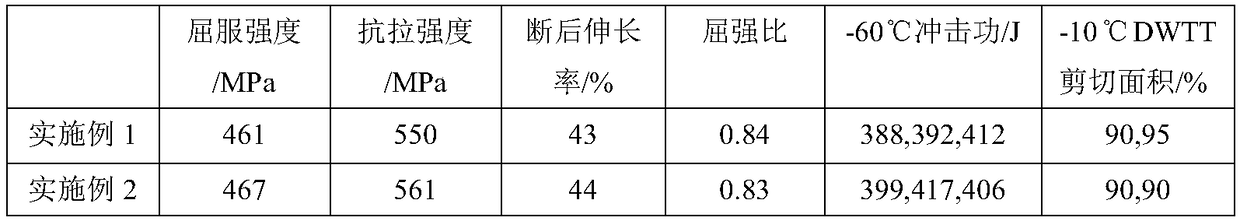

[0029] According to the scope of chemical composition and manufacturing method of the present invention, pretreatment of molten iron by KR—converter smelting—LF refining—RH vacuum degassing—continuous casting—continuous casting slab covered and slow cooling—continuous casting slab inspection and cleaning—slab heating—high pressure Water descaling—controlled rolling and controlled cooling—straightening—slow cooling of steel plate piles and other process steps to manufacture X65MS economical HIC-resistant pipeline steel with a thickness of 21mm (Example 1 and 2).

[0030] The continuous casting slab meets, P≤0.008; S≤0.0008; [N]≤0.002, [O]≤0.0010, [H]≤0.0001, the sum of the four types of inclusions A, B, C, and D is less than or equal to level 2, using continuous The segregation of the billet is controlled by light reduction and electromagnetic stirring technology, and the segregation of the billet meets the Mannesmann standard rating M1; the continuous casting billet is slowly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com