Pipeline steel plate for HIC (hydrogen induced cracking)-resistant X80 elbow pipes and manufacturing method thereof

A manufacturing method and steel plate technology, which is applied in the field of pipeline steel plate manufacturing for X80 bent pipes, can solve problems such as low production efficiency, difficulty in industrial production, and lack of feasibility in industrial production, and achieve high production efficiency, excellent HIC resistance, and on-site craft easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

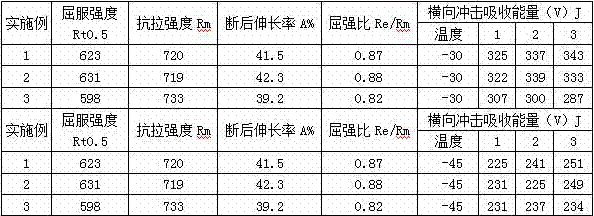

Examples

Embodiment Construction

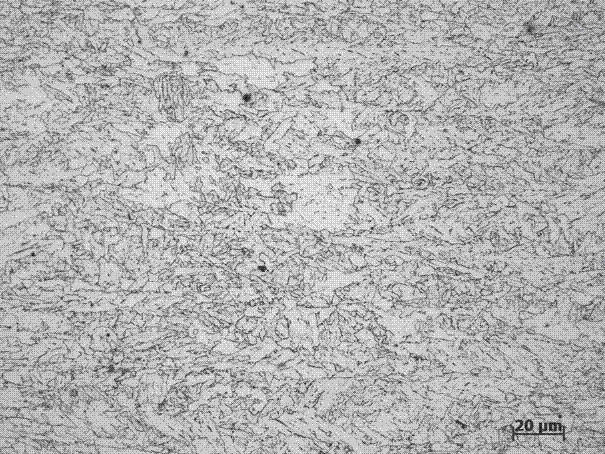

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0034] The manufacturing process of pipeline steel plates for HIC-resistant X80 steel grade bends is as follows: material preparation → converter or electric furnace smelting → out-of-furnace refining → continuous casting → slab reheating → specific TMCP process + stack cooling after water cooling → straightening.

[0035] The specific process steps are as follows: the smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, RH vacuum refining and continuous casting. During refining, the Ca / S ratio is controlled to not be lower than 1, and the B-type inclusions are controlled at 1.0 and below. In the following, the soft reduction process is adopted during continuous casting, the purpose is to improve the core segregation caused by the high Mn content. Manufacture a continuous casting sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com