High-temperature and flame-resistant colored adhesive tape, use of a substrate for its manufacture, and cable harness including such an adhesive tape

A cable harness, tape technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

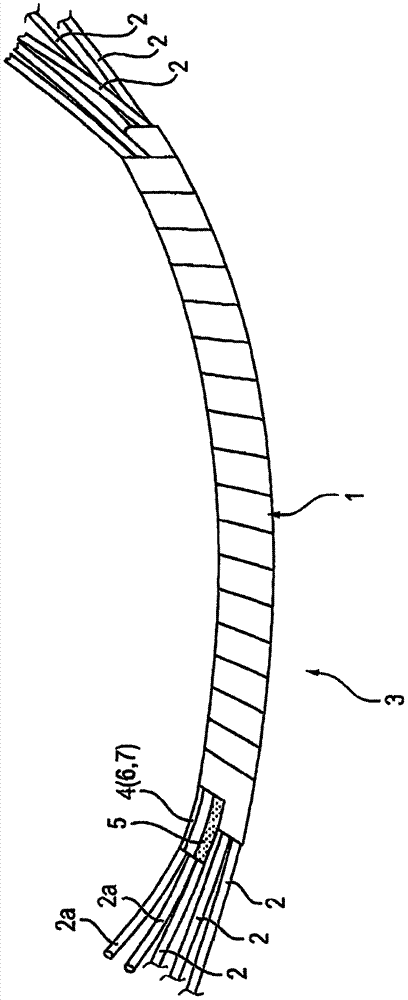

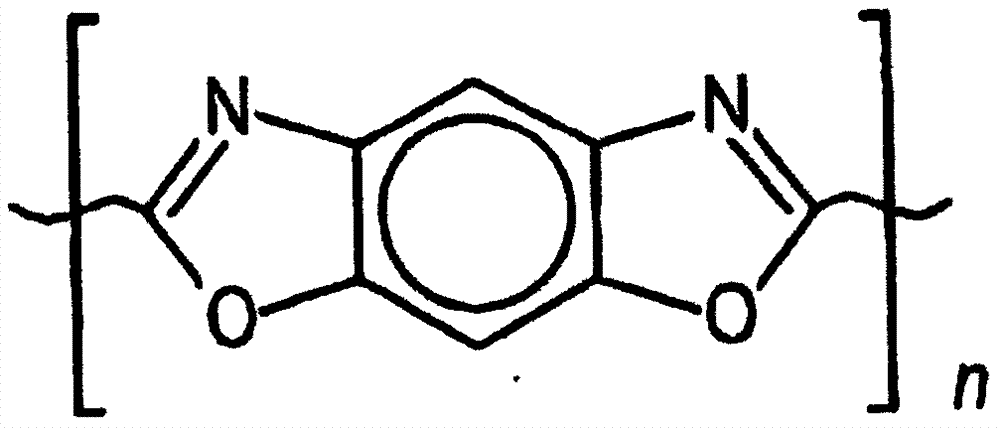

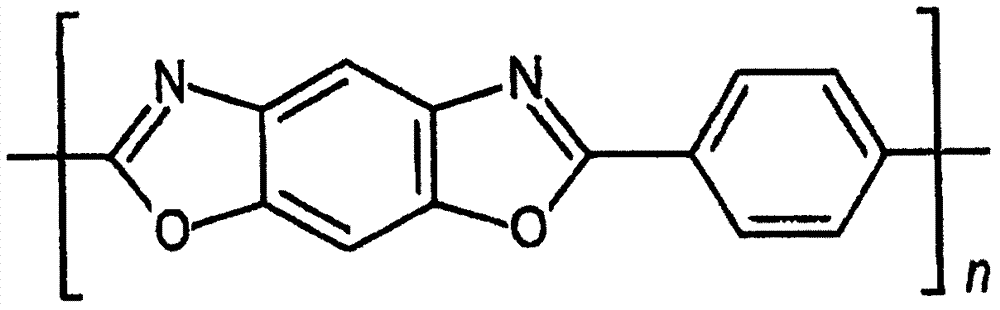

[0092] Embodiment 1: substrate 4 is made of Figure 7 The shown short poly-1,4-phenylene-1,3,4-oxadiazole and poly-4,4′-azobenzene-1,3,4-oxadiazole (orange) copolymer The fiber fabric is composed of a UV-curable acrylate adhesive (UV-Acrylatklebstoff) in the adhesive layer 5;

Embodiment 2

[0093] Embodiment 2: substrate 4 is made of Figure 7 The long poly-1,4-phenylene-1,3,4-oxadiazole and poly-4,4′-azobenzene-1,3,4-oxadiazole (orange) copolymers shown It is made of silk fiber fabric, and there is a UV-curable acrylate adhesive in the adhesive layer 5;

Embodiment 3

[0094] Embodiment 3: by Figure 7 The long poly-1,4-phenylene-1,3,4-oxadiazole and poly-4,4′-azobenzene-1,3,4-oxadiazole (orange) copolymers shown The substrate 4 made of silk fiber fabric has organic silicon adhesive in the adhesive layer 5 .

[0095] The other two examples 4 and 5 in the table relate to fabrics according to the present invention having (Example 4) and Adhesive tape 1 with substrate 4 composed of S (Example 5). Examples 4 and 5 show which values are achievable with common PBO / POD scrims.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com