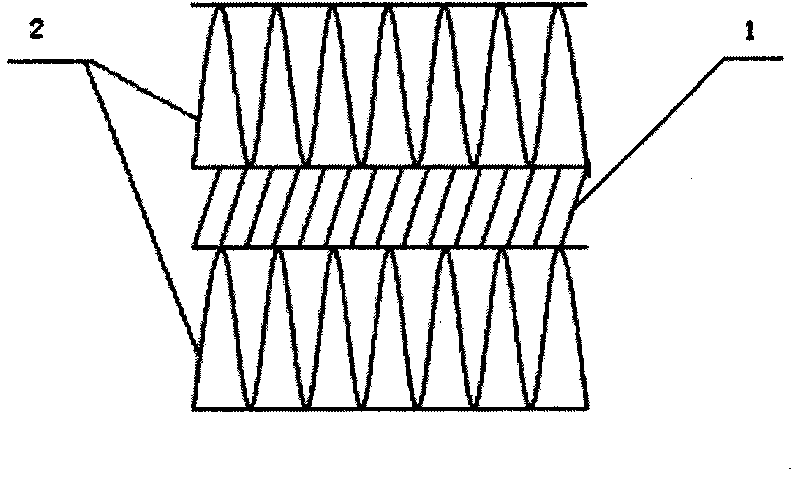

Composite sealing material and manufacturing method thereof

A composite sealing and mixture technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficult sealing requirements, high sealing specific pressure, poor creep and relaxation resistance, etc., and achieve good long-term pressure-resistant sealing performance, low compression set performance, and the effect of excellent compression rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

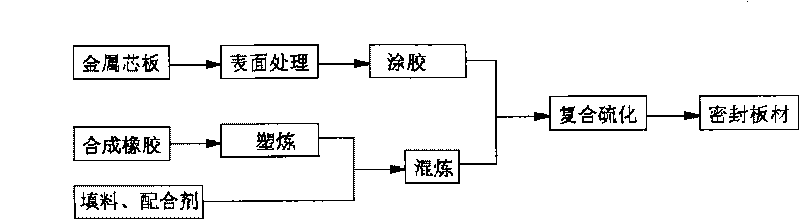

Method used

Image

Examples

Embodiment 1

[0031] After the 0.25mm thick carbon steel plate is sandblasted, a layer of isocyanate solution is uniformly coated on the surface and dried for use. Configure the following materials according to the weight ratio: nitrile rubber: 60, carbon black: 12.5, calcium carbonate: 7, talcum powder: 6, magnesium oxide: 3, barium sulfate: 4, sulfur: 0.1, anti-aging agent D: 0.2, DBP: 1.7, accelerator CZ: 0.15, accelerator TT: 0.15, zinc oxide: 1.0, stearic acid: 0.7, foaming agent H: 3.5. After masticating nitrile rubber with an open mill, press sulfur, carbon black, calcium carbonate, talcum powder, magnesium oxide, DBP, zinc oxide, stearic acid, anti-aging agent D, accelerator CZ, accelerator TT, foaming agent Add rubber in the order of H for mixing, take the mixed rubber material and form a sheet with a certain thickness of 2mm. Dissolve the plate with toluene to form glue, and evenly coat the glue on the surface of the treated steel plate, dry it, and then vulcanize it in an oven a...

Embodiment 2

[0033] Configure materials according to the following weight ratio: nitrile rubber: 50, neoprene: 20, carbon black: 14, calcium carbonate: 7, sulfur: 0.1, antioxidant D: 0.2, DBP: 1.7, accelerator CZ: 0.15, accelerator Agent TT: 0.15, zinc oxide: 1.0, magnesium oxide: 1, stearic acid: 0.7, foaming agent H: 4. Prepare the mixed rubber as described in Example 1, use a calender to evenly coat the rubber on the surface of the steel plate that has been treated as described in Example 1, and vulcanize according to the method in Example 1 to obtain the sealing plate of the present invention.

Embodiment 3

[0035] The compounded rubber material prepared in Example 2 was evenly coated on the surface of the stainless steel plate treated with KH550 coupling agent, and the rest of the process was as in Example 2 to obtain the sealing plate of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com