Stem cell sponge bracket, as well as preparation method and application thereof

A stem cell and sponge technology, applied in the field of biological materials and stem cells, can solve the problems of poor adhesion and mechanical properties of gelatin, unable to activate cell response, and lack of antibacterial ability, so as to promote wound healing, good application prospects, and good The effect of mesh connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

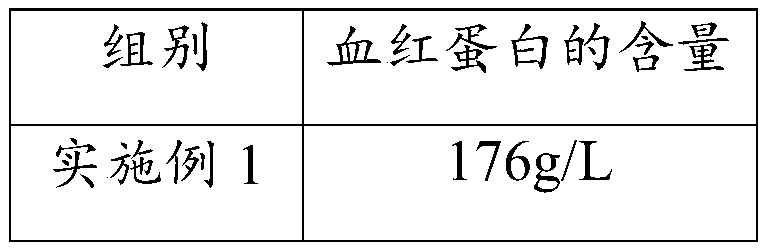

Embodiment 1

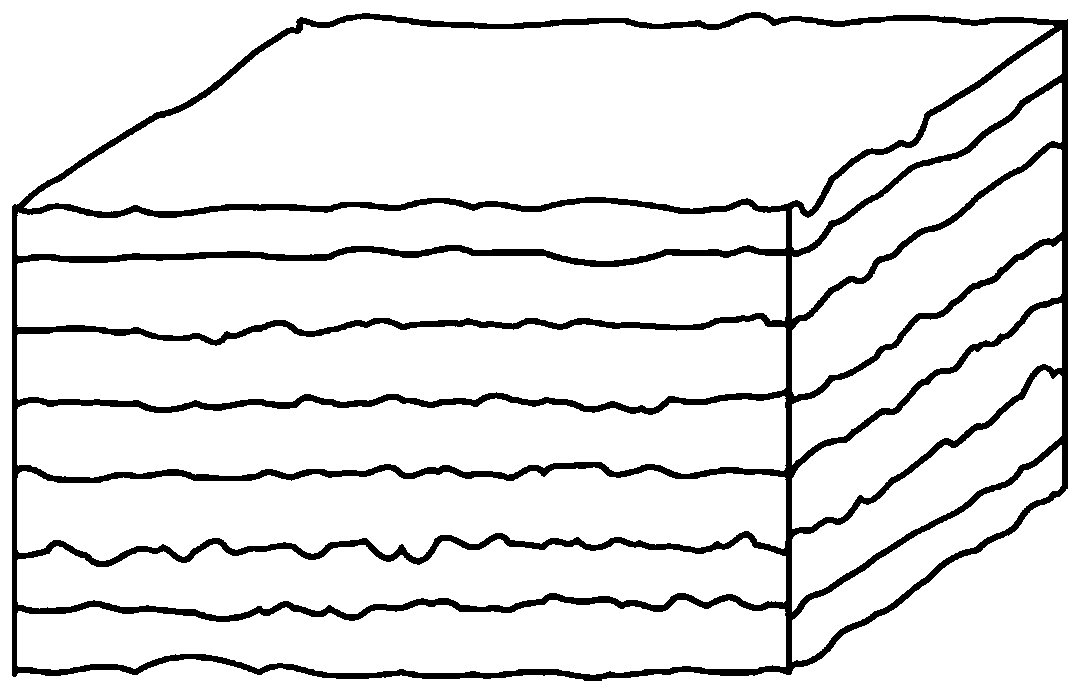

[0089] This embodiment provides a stem cell sponge scaffold prepared by the following steps:

[0090] (a) Add 0.2 g of chitosan with a viscosity of 200 mPa.s into 10 mL of 85% w / w acetic acid to dissolve, and dissolve 0.7 g of polylactic acid with a weight average molecular weight of 350,000 in 10 mL of hexafluoroisopropanol and stir to dissolve.

[0091] (b) Chitosan solution and polylactic acid solution are mixed evenly according to the weight ratio of 4:6 and then injected into the syringe. At 18KV, a planar nanofibrous membrane was obtained after electrospinning for one hour.

[0092] (c) putting the obtained nanofibrous membrane with planar structure into glutaraldehyde vapor for cross-linking, and cross-linking for 10 hours. Put the cross-linked nanofibers into a vacuum drying oven for drying, and take them out after 3 days.

[0093] (d) Put the dried nanofiber membrane into 0.1mol / L sodium borohydride aqueous solution for foaming, take it out after 10 hours, rinse it ...

Embodiment 2

[0096] This embodiment provides a stem cell sponge scaffold prepared by the following steps:

[0097] (a) 0.4 g of chitosan with a viscosity of 200 mPa.s was dissolved in 10 mL of 85% w / w acetic acid, and 0.7 g of polylactic acid with a weight average molecular weight of 350,000 was dissolved in 10 mL of hexafluoroisopropanol and stirred to dissolve.

[0098] (b) Chitosan solution and polylactic acid solution are mixed evenly according to the weight ratio of 3:7 and then injected into the syringe. The advancing speed of the syringe is adjusted to 1.5mL / h, the distance between the needle and the receiving device is 15cm, and the voltage between the two At 27KV, a nanofibrous membrane with a planar structure was obtained after electrospinning for one hour.

[0099] (c) putting the obtained nanofibrous membrane with planar structure into glutaraldehyde vapor for cross-linking, and cross-linking for 10 hours. Put the cross-linked nanofibers into a vacuum drying oven for drying, a...

Embodiment 3

[0103] This embodiment provides a stem cell sponge scaffold prepared by the following steps:

[0104] (a) Add 0.2 g of chitosan with a viscosity of 400 mPa.s to 10 mL of 85% w / w acetic acid to dissolve, and dissolve 0.7 g of polylactic acid with a weight average molecular weight of 350,000 in 10 mL of hexafluoroisopropanol and stir to dissolve.

[0105] (b) Chitosan solution and polylactic acid solution are mixed evenly according to the weight ratio of 3:7 and then injected into the syringe. The advancing speed of the syringe is adjusted to 1.5mL / h, the distance between the needle and the receiving device is 15cm, and the voltage between the two At 18KV, a planar nanofibrous membrane was obtained after electrospinning for one hour.

[0106] (c) putting the obtained nanofibrous membrane with planar structure into glutaraldehyde vapor for cross-linking, and cross-linking for 10 hours. Put the cross-linked nanofibers into a vacuum drying oven for drying, and take them out after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com