Double-layer composite aerogel for inhibiting biofilm formation, preparation method and application thereof

A technology for inhibiting biofilm and double-layer composite, which is applied in the field of preparation and double-layer composite airgel that inhibits the formation of biofilm. It can solve the problems that the formation of surface biofilm cannot be inhibited, and achieve good water evaporation performance and good compression resilience. The effect of maintaining shape integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

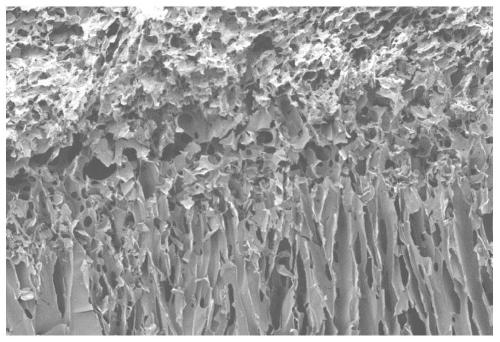

[0051] The present embodiment prepares chitosan airgel (CS airgel), and concrete steps are as follows:

[0052] (1) Take 2g chitosan powder, add 99mL deionized water and 1mL acetic acid, stir to form a transparent solution, which is 2% shell

[0053] polysaccharide solution;

[0054] (2) adjust the pH of chitosan solution to neutrality with 1% sodium hydroxide solution;

[0055] (3) the chitosan solution adjusted to neutrality is carried out orientation freezing with liquid nitrogen and the time of orientation freezing is 30 minutes;

[0056] (4) The frozen chitosan solution is freeze-dried to obtain the chitosan airgel;

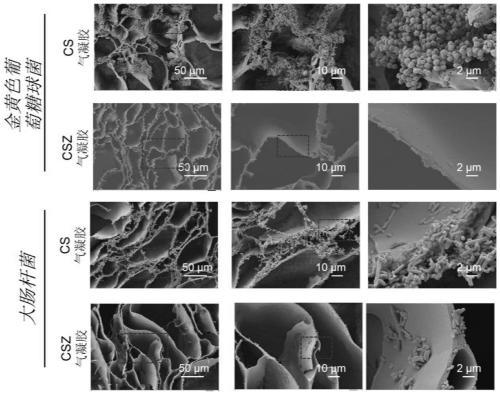

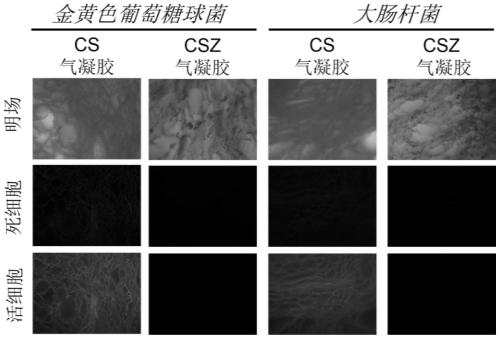

[0057] Chitosan airgel soaked in 10 5 CFU / mL E. coli solution and Staphylococcus aureus solution, and shaken at 37°C for 3 days, after a series of processes such as dehydration, fixation and freeze-drying, the samples were observed with a scanning electron microscope, and the results were as follows: figure 1 . It can be seen from the figure that a larg...

Embodiment 2

[0060] The present embodiment prepares chitosan / zinc oxide nanoparticle airgel (CZ airgel), and concrete steps are as follows:

[0061] (1) Get 2g chitosan powder, add 99mL deionized water and 1mL acetic acid, stir into a transparent solution, which is 2% chitosan solution;

[0062] (2) adjust the pH of chitosan solution to neutrality with 1% sodium hydroxide solution;

[0063] (3) Zinc oxide nanoparticles are configured into a 2mg / mL aqueous dispersion, which is added dropwise to the chitosan solution and the mass ratio of zinc oxide nanoparticles to chitosan is 1:50, stirred evenly to obtain Chitosan / zinc oxide nanoparticle mixture;

[0064] The chitosan / zinc oxide nanoparticle mixed liquid is oriented frozen with liquid nitrogen and the time of oriented freezing is 30 minutes, and then dried in a freeze dryer to obtain the chitosan / zinc oxide nanoparticle aerogel;

[0065] image 3 It is a scanning picture of chitosan / zinc oxide nanoparticle airgel, and it can be seen fr...

Embodiment 3

[0073] The present embodiment prepares chitosan / silver nanoparticle airgel (CSS airgel), and concrete steps are as follows:

[0074] (1) Take 2g chitosan powder, add 99mL deionized water and 1mL acetic acid, stir to form a transparent solution, which is 2% shell

[0075] polysaccharide solution;

[0076] (2) adjust the pH of chitosan solution to neutrality with 1% sodium hydroxide solution;

[0077] (3) Silver nanoparticles are configured into a 2mg / mL aqueous dispersion, which is added dropwise to the chitosan solution and the silver nanoparticles

[0078] The mass ratio of particle and chitosan is 1:50, stirs evenly, obtains chitosan / silver nano particle mixed solution;

[0079] (4) The chitosan / silver nanoparticle mixed liquid was carried out orientation freezing with liquid nitrogen and the orientation freezing time was 30 minutes, and then

[0080] Finally, dry in a freeze dryer to obtain chitosan / silver nanoparticle airgel;

[0081] Soak the chitosan / silver nanoparti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com