Fe base lithium sale compound anode materials and its making method

A composite positive electrode material and composite material technology, applied in the field of positive electrode material and its preparation, can solve the problems of low ion diffusion coefficient and electronic conductivity, low battery volume specific capacity, poor high rate discharge performance, etc. The effect of a wide range of sources and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

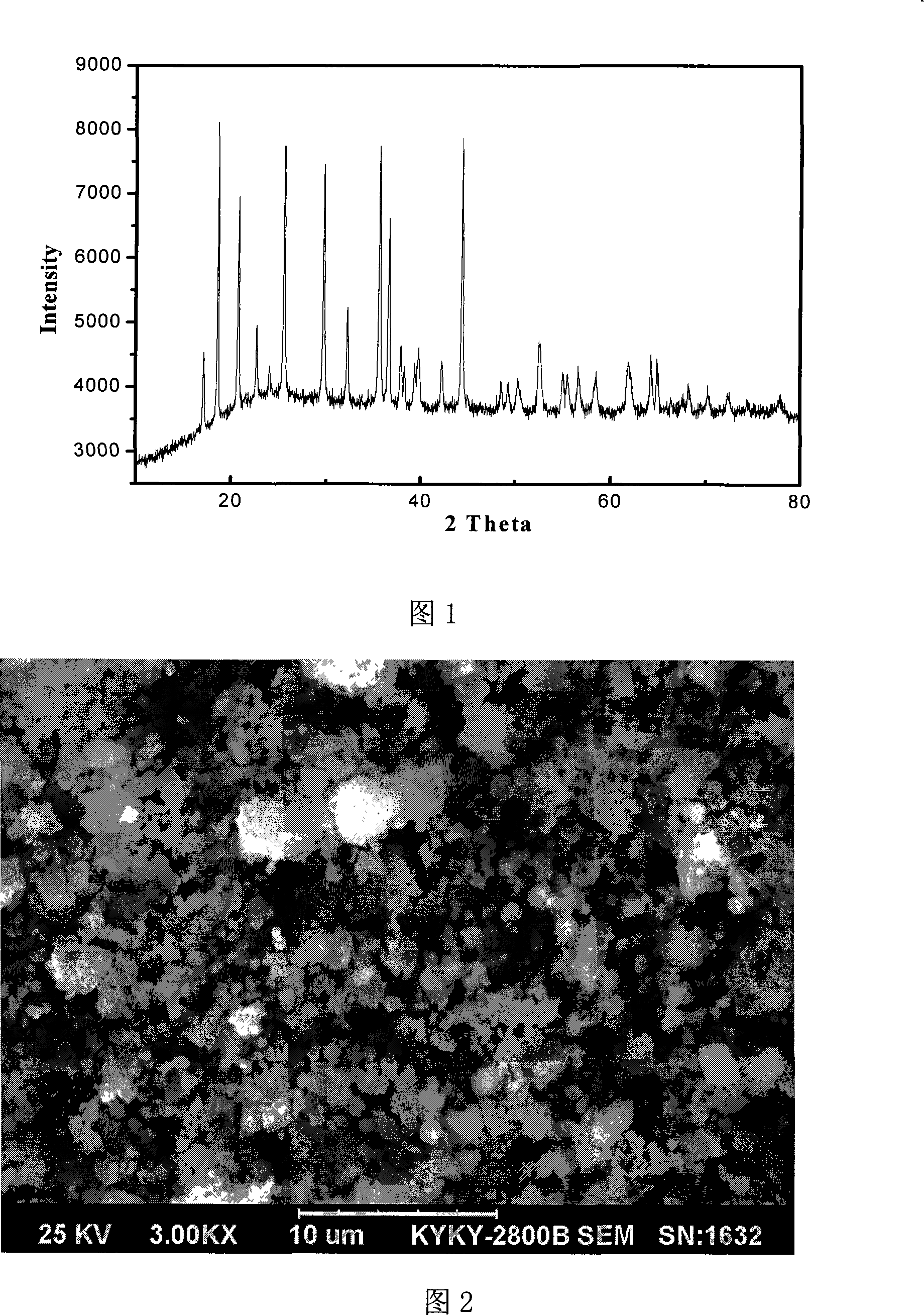

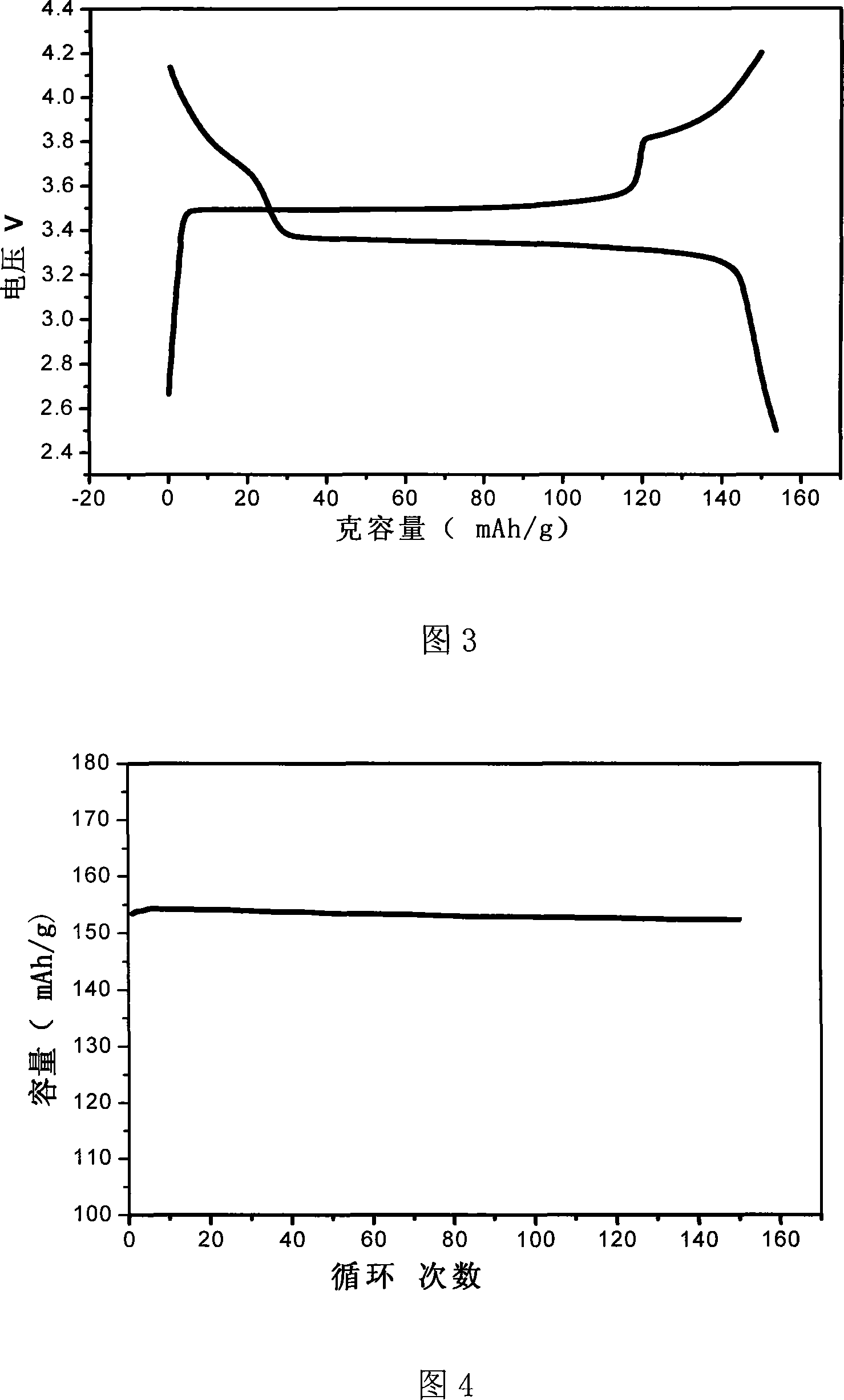

[0032] 8.5Kg lithium iron phosphate LiFePO 4 With 1.5Kg nickel cobalt manganese lithium LiNi 0.33 co 0.33 mn 0.33and 0.1Kg of nano-carbon are mixed evenly, put into the Q50 fusion machine of Luoyang Qixing Technology Development Co., Ltd., and carry out mechanical fusion treatment at a speed of 1100rpm for 2 hours, and then pass through Gongyi Songling Mining Machinery Co., Ltd. CXJ-100- I-type magnetic separator removes magnetic substances under a magnetic field strength of 7000 Gauss, and then sieves through a 325-mesh fine sieve and vacuum packs to obtain iron-based lithium salt composite cathode materials. The specific surface of the raw material lithium iron phosphate is 40.12m 2 / g, the tap density is 1.23g / cm 3 . As shown in Figure 1, the prepared iron-based lithium salt composite cathode material, using Cu target K α ray, wavelength 0.154056nm, obtained X-ray diffraction pattern, it can be seen from the figure that the crystal of the material is olivine structure...

Embodiment 2

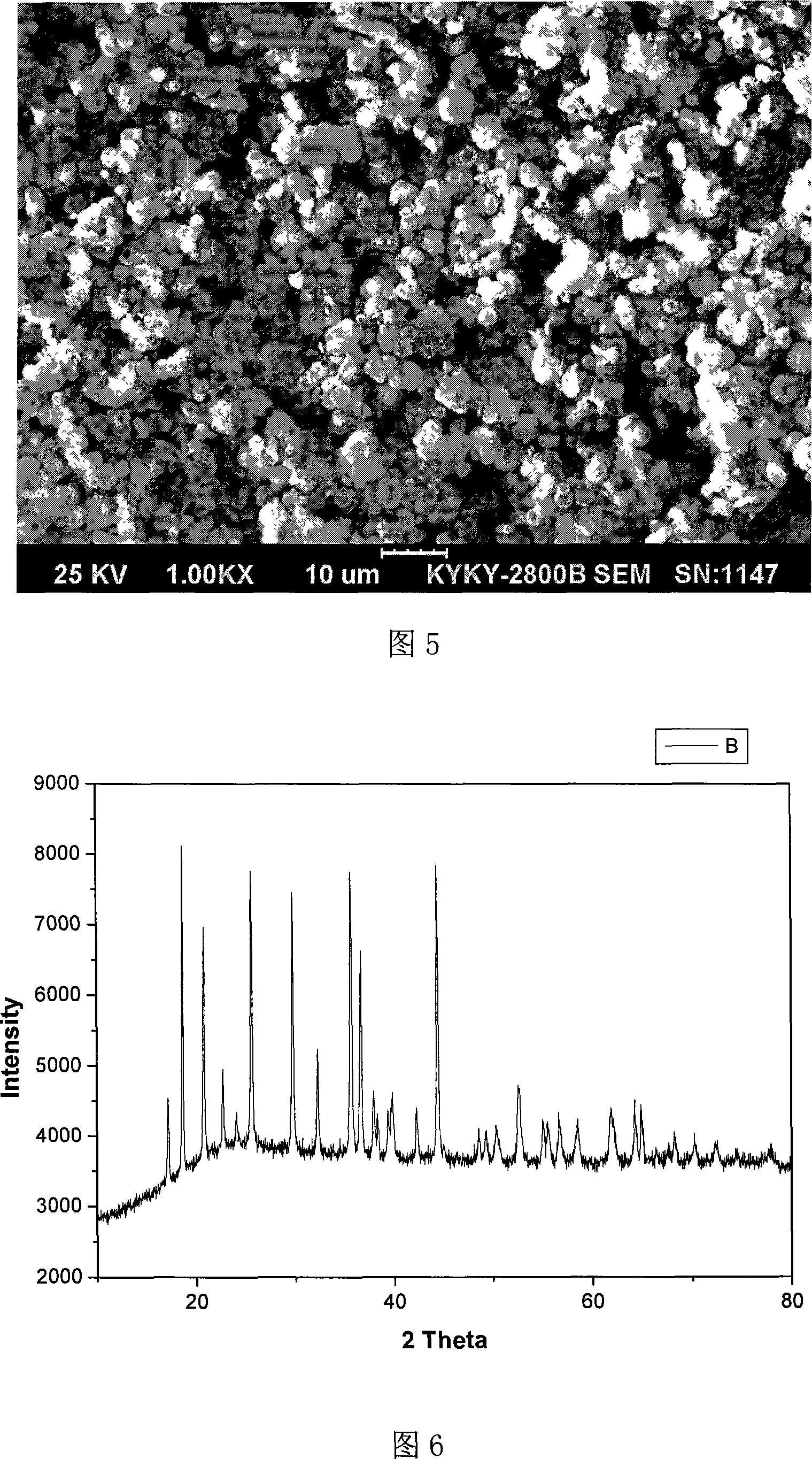

[0035] 8Kg lithium ferrous phosphate and 2Kg nickel cobalt aluminum lithium LiNi 0.33 co 0.33 al 0.33 and 0.15Kg of nano-carbon are mixed evenly, put into a fusion machine for fusion treatment at 1100rpm for 2 hours, then remove the magnetic substances through a 12000 Gauss ultra-high-strength magnetic separator, and then sieve through a 325-mesh fine sieve and vacuum pack to obtain the product. The specific surface of the raw material lithium iron phosphate is 40.12m 2 / g, the tap density is 1.23cm 3 . Using the same instrument and method as in Example 1, it is measured that the material crystal is an olivine structure, the space group is Pbnm, the microscopic shape of the material is spherical or a spherical-like shape with a ratio of length to diameter of 1.8, and the average particle size is 7 μm. The specific surface area is 17.47m 2 / g, tap density 1.61g / cm 3 .

[0036] Electrodes were prepared according to the same method as in Example 1, and the electrochemical ...

Embodiment 3

[0038] 9Kg lithium ferrous phosphate and 1Kg nickel cobalt manganese lithium LiNi 0.05 co 0.05 mn 0.9 and 0.5Kg of conductive carbon black were evenly mixed, put into a fusion machine and fused for 4 hours at a speed of 200 rpm, then removed the magnetic substance through a 3000 Gauss ultra-high-strength magnetic separator, and then sieved through a 200-mesh fine sieve and vacuum-packed to obtain the product. The specific surface of the raw material lithium iron phosphate is 41.12m 2 / g, the tap density is 1.23cm 3 . Using the same instrument and method as in Example 1, it is measured that the crystal of the material is an olivine structure, the space group is Pbnm, the microscopic shape of the material is spherical or a spherical-like shape with an aspect ratio of 2.5, and the average particle size is 7 μm. The specific surface area is 18.36m 2 / g, tap density 1.65g / cm 3 .

[0039] Electrodes were prepared according to the same method as in Example 1, and the electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com