Aerosol paint and preparation method thereof

A technology of aerosol paint and fumed silica, which is applied in coatings, wax coatings, etc., can solve the problems of storage stability, weather resistance, and beneficial effects of wood wax oil coatings, easy color change and other problems. Migration, unfavorable product export and other problems, to achieve the effect of excellent atomization, bright color, and improved storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

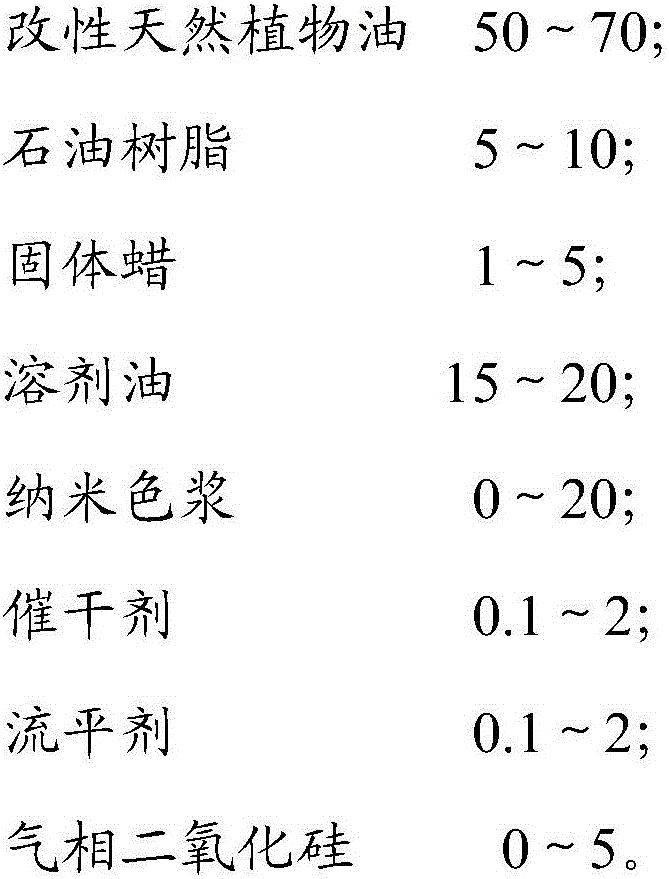

Method used

Image

Examples

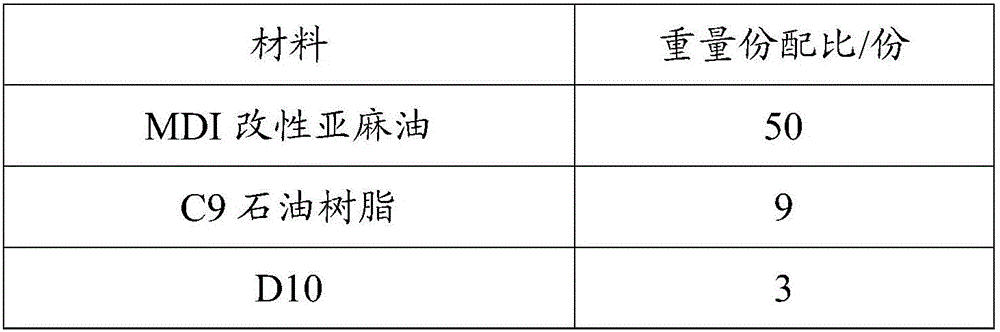

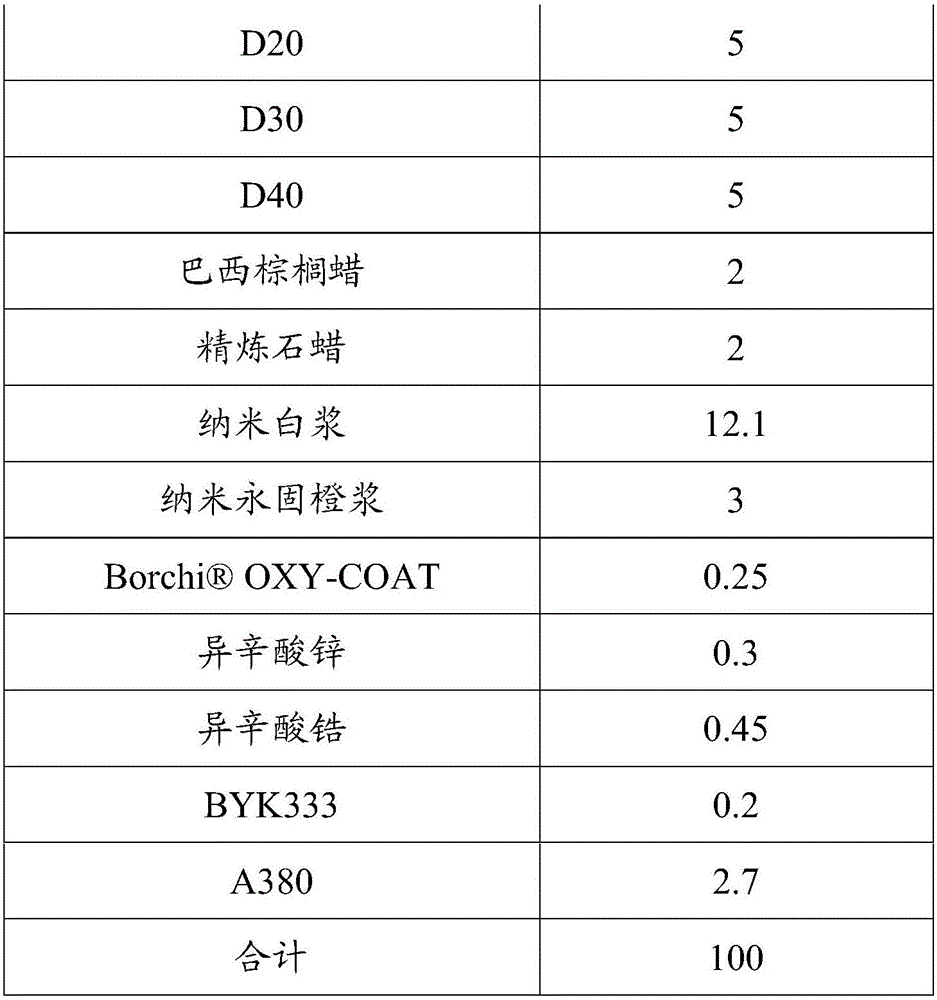

Embodiment 1

[0039] According to the proportion by weight in Table 1.1, add 80% solvent oil, add petroleum resin under stirring, and continue to disperse for 5-10 minutes after it is completely dissolved, then add modified natural vegetable oil, fumed silica, nano color paste, Leveling agent, dispersed at high speed until uniform, heated at 50°C for 8 minutes;

[0040] Add 20% of the mixture of odorless mineral spirits and solid wax into the heating cylinder, heat to 80°C under airtight conditions until completely dissolved and keep warm for 5-10 minutes;

[0041] Add S2 to S1 under stirring, disperse until uniform, cool down to room temperature, and finally add drier, disperse evenly to obtain wood wax oil;

[0042] Put stirring beads into the aerosol can, fill the wood wax oil and propellant into the aerosol can according to the weight ratio in Table 1.2, put the valve, vacuumize, seal, inflate, press the head, and press the cap. That is to obtain the wood wax oil aerosol paint A, where...

Embodiment 2

[0049] According to the proportion by weight in Table 2.1, add 80% solvent oil, add petroleum resin under stirring, and continue to disperse for 5-10 minutes after it is completely dissolved, then add modified natural vegetable oil, fumed silica, nano color paste, Leveling agent, dispersed at high speed until uniform, heated at 50°C for 8 minutes;

[0050] Add 20% of the mixture of odorless mineral spirits and solid wax into the heating cylinder, heat to 80°C under airtight conditions until completely dissolved and keep warm for 5-10 minutes;

[0051] Add S2 to S1 under stirring, disperse until uniform, cool down to room temperature, and finally add drier, disperse evenly to obtain wood wax oil;

[0052] Put stirring beads into the aerosol can, fill the wood wax oil and propellant into the aerosol can according to the weight ratio in Table 2.2, put the valve, vacuumize, seal, inflate, press the head, and press the cap. That is to obtain wood wax oil aerosol paint B, wherein the...

Embodiment 3

[0058] According to the proportion by weight in Table 3.1, add 80% solvent oil, add petroleum resin under stirring, and continue to disperse for 5-10 minutes after it is completely dissolved, then add modified natural vegetable oil, fumed silica, nano color paste, Leveling agent, dispersed at high speed until uniform, heated at 50°C for 8 minutes;

[0059] Add 20% of the mixture of odorless mineral spirits and solid wax into the heating cylinder, heat to 80°C under airtight conditions until completely dissolved and keep warm for 5-10 minutes;

[0060] Add S2 to S1 under stirring, disperse until uniform, cool down to room temperature, and finally add drier, disperse evenly to obtain wood wax oil;

[0061] Put stirring beads into the aerosol can, fill the wood wax oil and propellant into the aerosol can according to the weight ratio in Table 3.2, put the valve, vacuumize, seal, inflate, press the head, and press the cap. That is to obtain wood wax oil aerosol paint C, wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com