Method for avoiding ribbon windings

A cross-winding, cross-winding bobbin technology, applied in the field of avoiding lap winding, can solve the problems of high mechanical and control expenses, complex or expensive, unsatisfactory, etc., to prevent lap winding , Eliminate the effect of lap coil winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

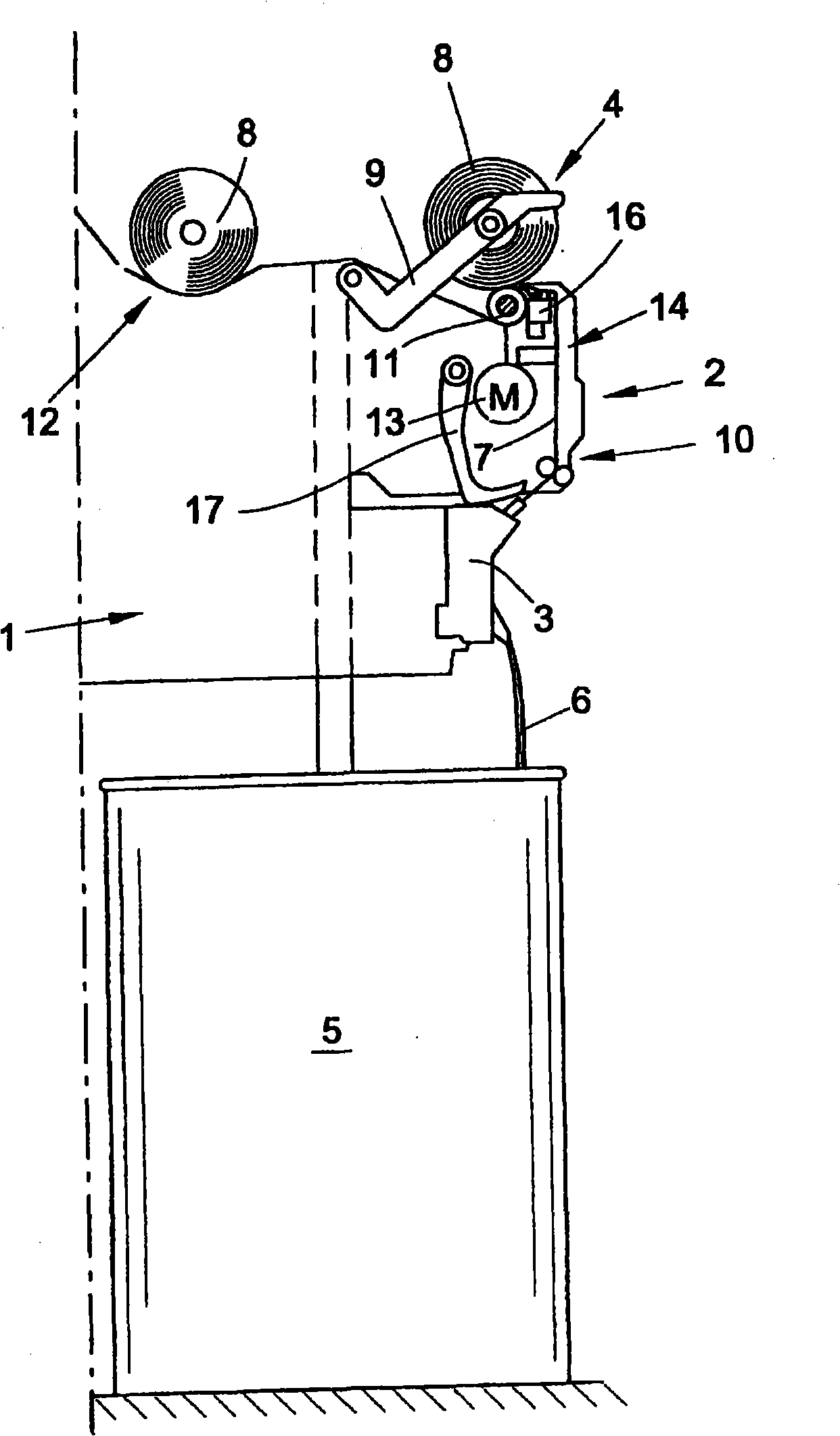

[0028] figure 1 A side view of one half of a textile machine 1 producing cross-wound bobbins is schematically shown in an embodiment of an open-end rotor spinning machine. As is known, a textile machine of this type has between its end frames (not shown) a large number of similar workstations 2 which, among other things, each have a spinning unit 3 and a winding device 4 . The fiber strip 6 stored in the spinning container 5 is processed in the spinning unit 3 into yarns 7, which are then wound on the winding device 4 to form cross-wound bobbins. The completed cross-wound bobbin 8 is conveyed, for example, by means of a cross-wound bobbin transport mechanism 12 to a loading station (not shown) arranged at the end of the machine.

[0029] as in figure 1 As shown in , each workstation 2 has other processing mechanisms besides the spinning unit 3 and the winding device 4 , such as a thread take-off mechanism 10 , a suction nozzle 17 or a waxing device 14 . The function of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com