Method and device for winding yarn

A winding device and bobbin technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem of low commodity value and achieve the effect of preventing doffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

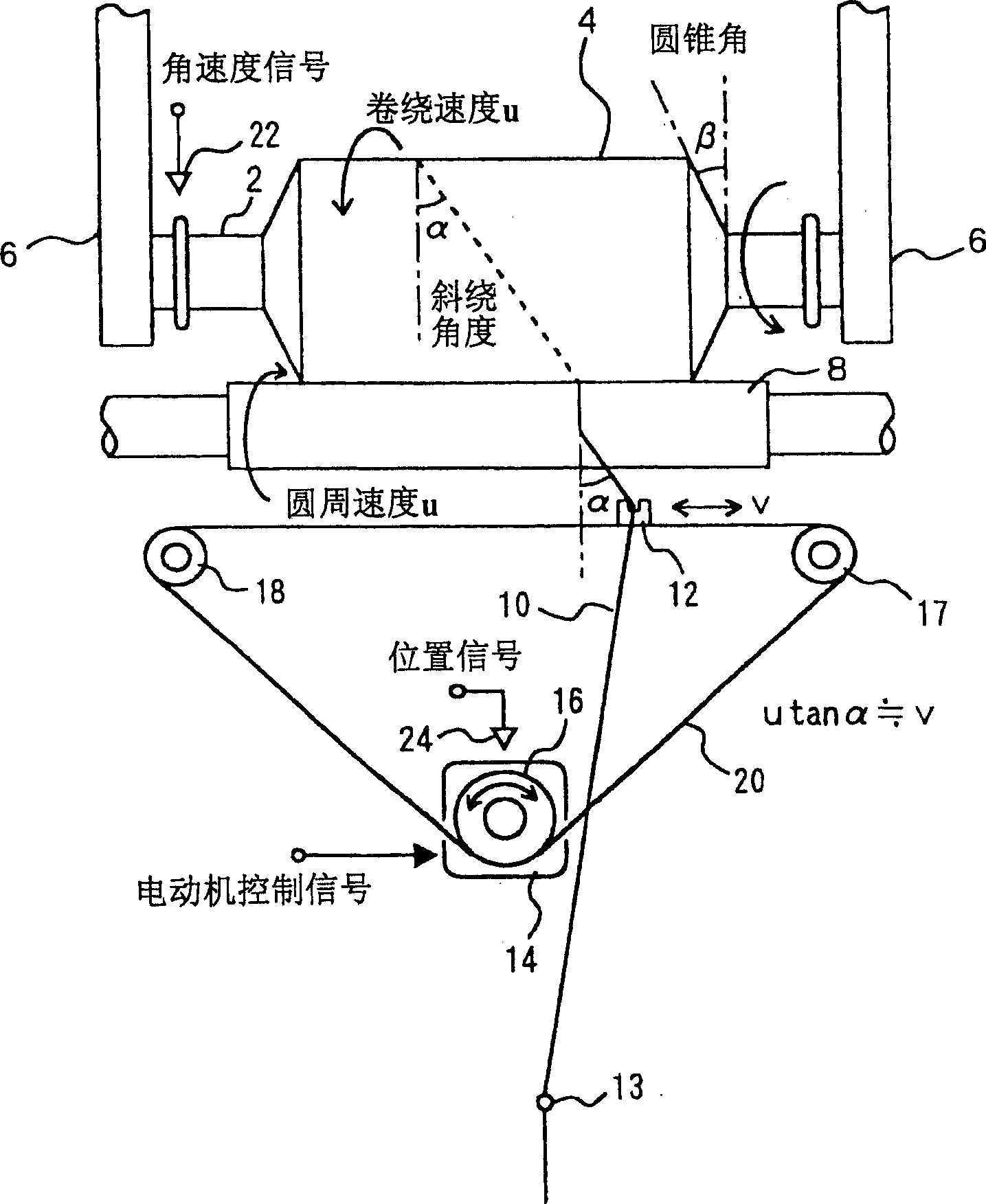

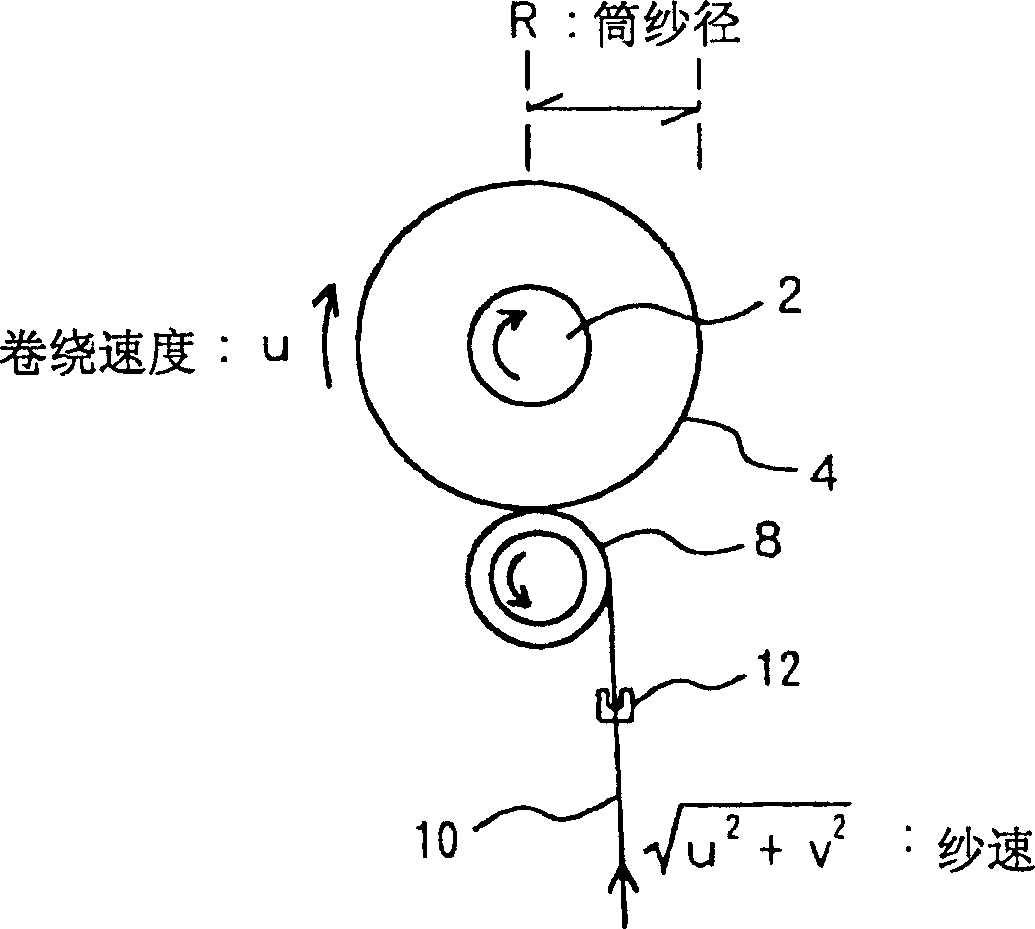

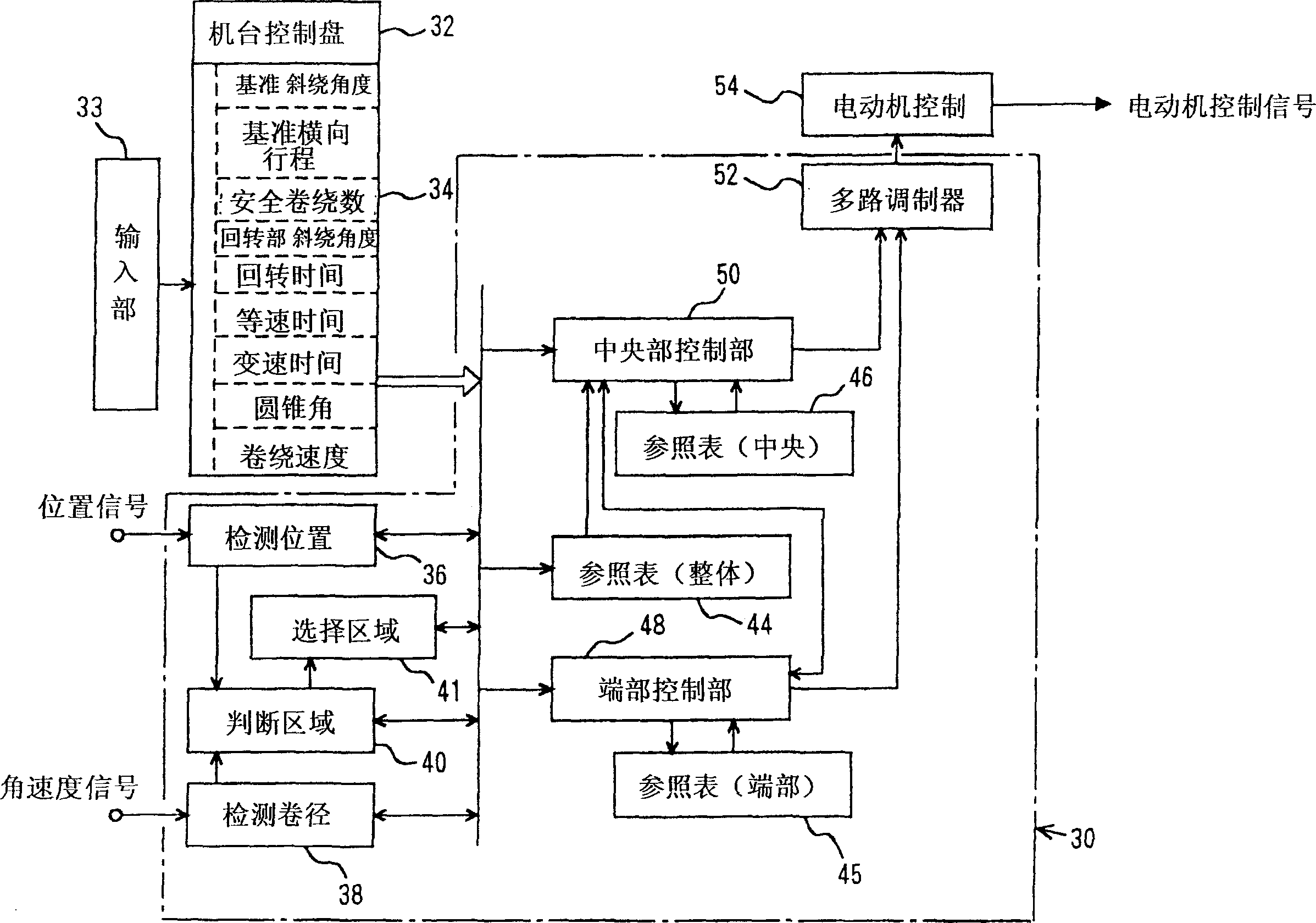

[0041] exist Figure 1 to Figure 12 Embodiments and variations thereof are shown. In the examples, the winding of the false-twisted yarn in the false-twisting machine was taken as an example, but it is not limited thereto. In addition, although the yarn winding method is segmental precision winding, it may be only precision winding or other yarn winding methods. In these figures, 2 is a bobbin, on which the yarn is wound (coiled) to form a bobbin 4, and the bobbin 2 is freely rotatably supported by a hanger 6 that can swing freely, and the contact roller 8 serves as The rollers are driven to rotate the bobbins 4 . Since the slippage between the contact roller 8 and the package 4 is neglected, the peripheral speed of the contact roller 8 and the winding speed of the package 4 have the same value u. Alternatively, the package 4 may be rotated by a drive shaft provided on the hanger 6 side.

[0042] The yarn 10 of chemical fiber or synthetic fiber etc. is fed through the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com