Control method for stabilizing and enhancing sintered ring cooling wind temperature while smelting steel

A technology for iron and steel smelting and control devices, which is applied in furnace control devices, auxiliary non-electric temperature control, and electric temperature control, etc., and can solve the problems of reduced exhaust gas flow, instability, and impact on the steam output of waste heat boilers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below by way of examples, but not limited to examples.

[0033] Take Yunnan Yuxi Xinxing Iron and Steel Co., Ltd. as an example.

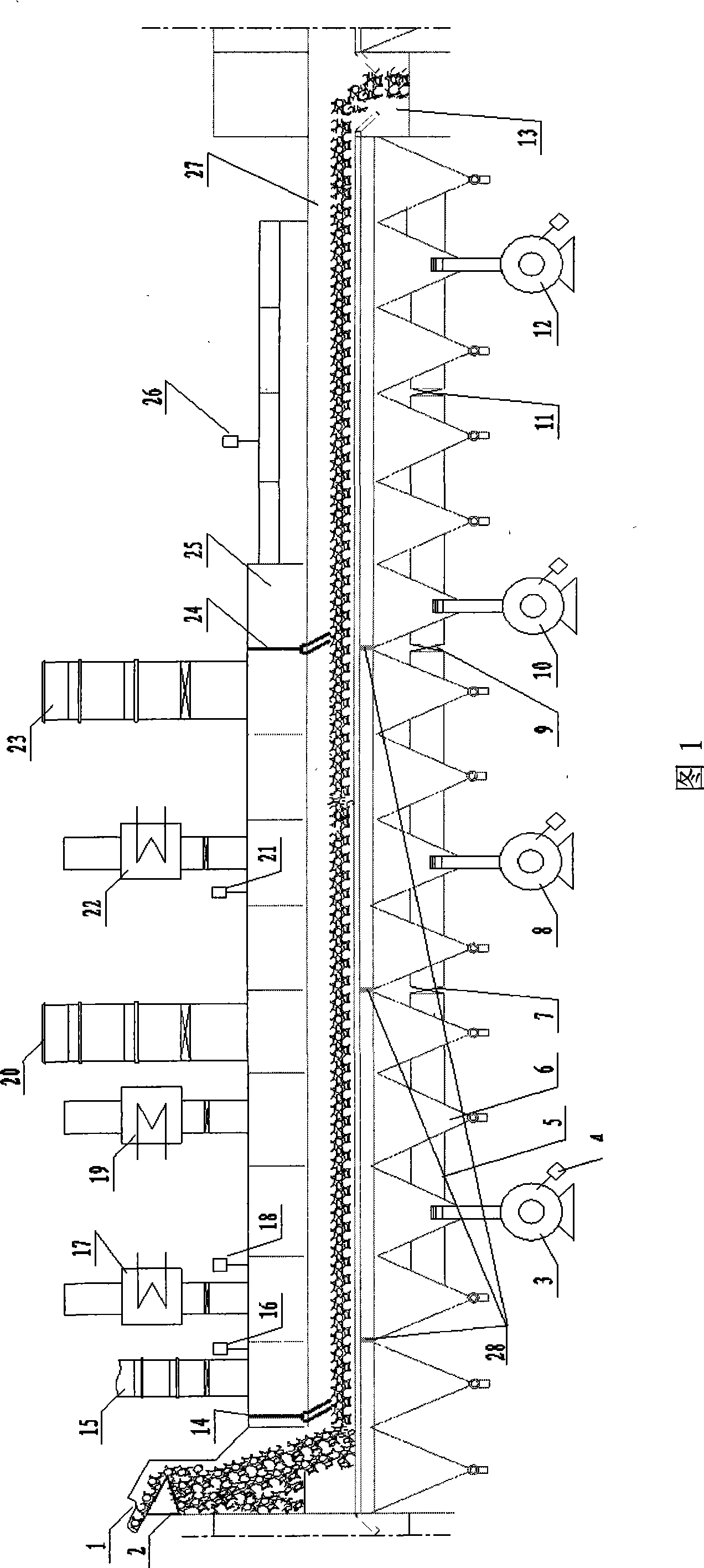

[0034] Technical parameters of sintering cooler:

[0035] 1. Sintering machine: 90m 2

[0036] 2. Cooling machine: 125m 2

[0037] 3. Cooling machine cooling fan: 206,000 m 3 / h, 4 units in total, motor power 355kW

[0038] 4. Mine temperature at the feed inlet of the cooler: average 750°C

[0039] 5 Mine temperature in the upper part of the 11# air box of the cooler: controlled below 200°C

[0040] 6. Mine temperature at the outlet of the cooling machine: controlled below 150°C

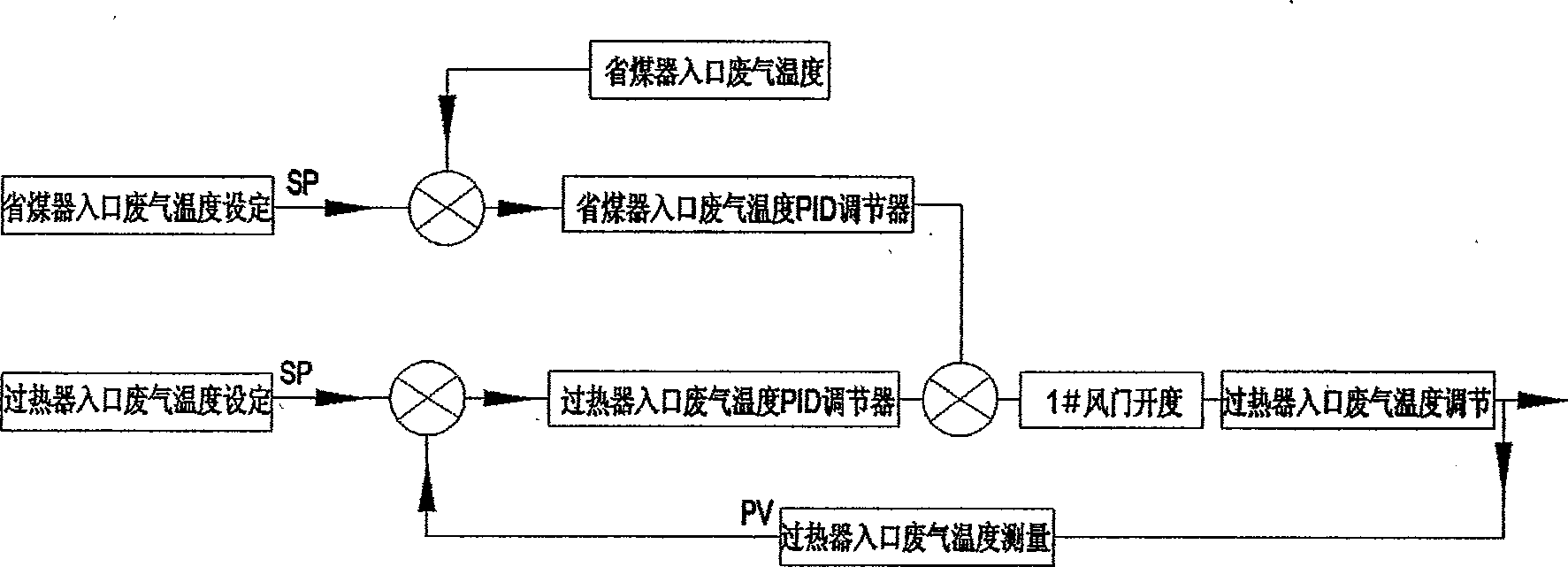

[0041] 7. The thickness of the inner material layer of the cooling machine trolley is controlled at 1100±100mm

[0042] 8. The exhaust gas temperature at the inlet of the steam superheater is controlled at 450±50°C

[0043] 9. The exhaust gas temperature at the inlet of the economizer is controlled at 210±30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com