Drilling tool

A drilling tool and tool technology, which is used in drilling tool accessories, manufacturing tools, drilling/drilling equipment, etc. The effect of long anti-breakage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] based on Figure 4 ~ Figure 11 Specific examples of the present invention will be described.

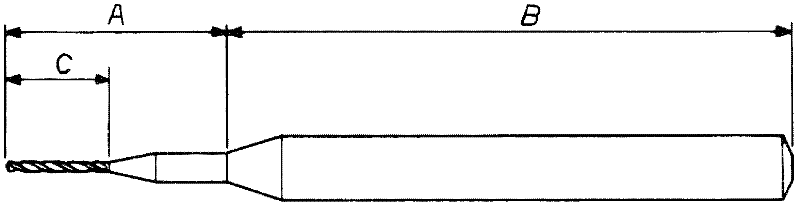

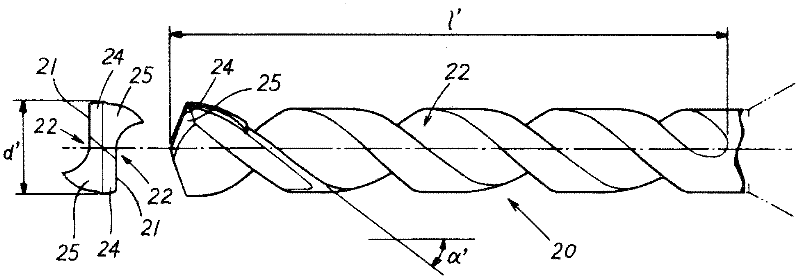

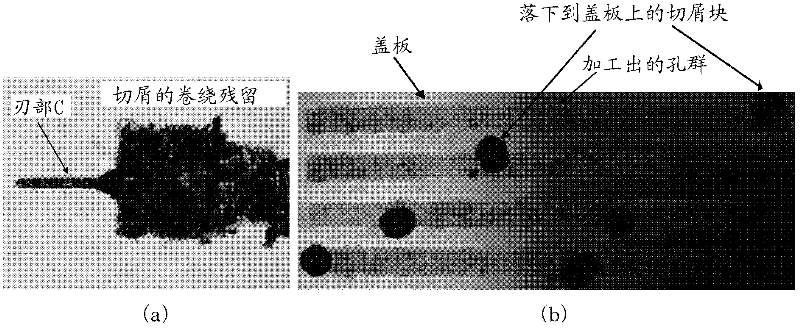

[0055] This embodiment is a drilling tool as follows: one or more cutting edges are provided at the end of the tool main body 1, and a plurality of helical cutting edges are provided on the outer periphery of the tool main body 1 from the end of the tool toward the base end side. Chip removal flutes 2, 3, the plurality of chip removal flutes 2, 3 include one main flute and more than one auxiliary flute, the auxiliary flute 3 is connected to the middle part of the main flute 2, and the The helix angles of the main flute 2 and the sub flute 3 are set to approximately equal angles at the base end side of the tool from the connecting portion 4 where the main flute 2 and the sub flute 3 are connected. The groove length is set to be 50% to 95% of the groove length of the main groove 2, and the auxiliary groove 3 is provided at a predetermined position from the connection setting pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com