Spinning machine and method for interrupting yarn production on a spinning machine

A yarn manufacturing and spinning machine technology, applied to spinning machines, textiles and papermaking, open-end spinning machines, etc., can solve problems affecting efficiency, time-consuming, spinning process delays, etc., and achieve reliable grasping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

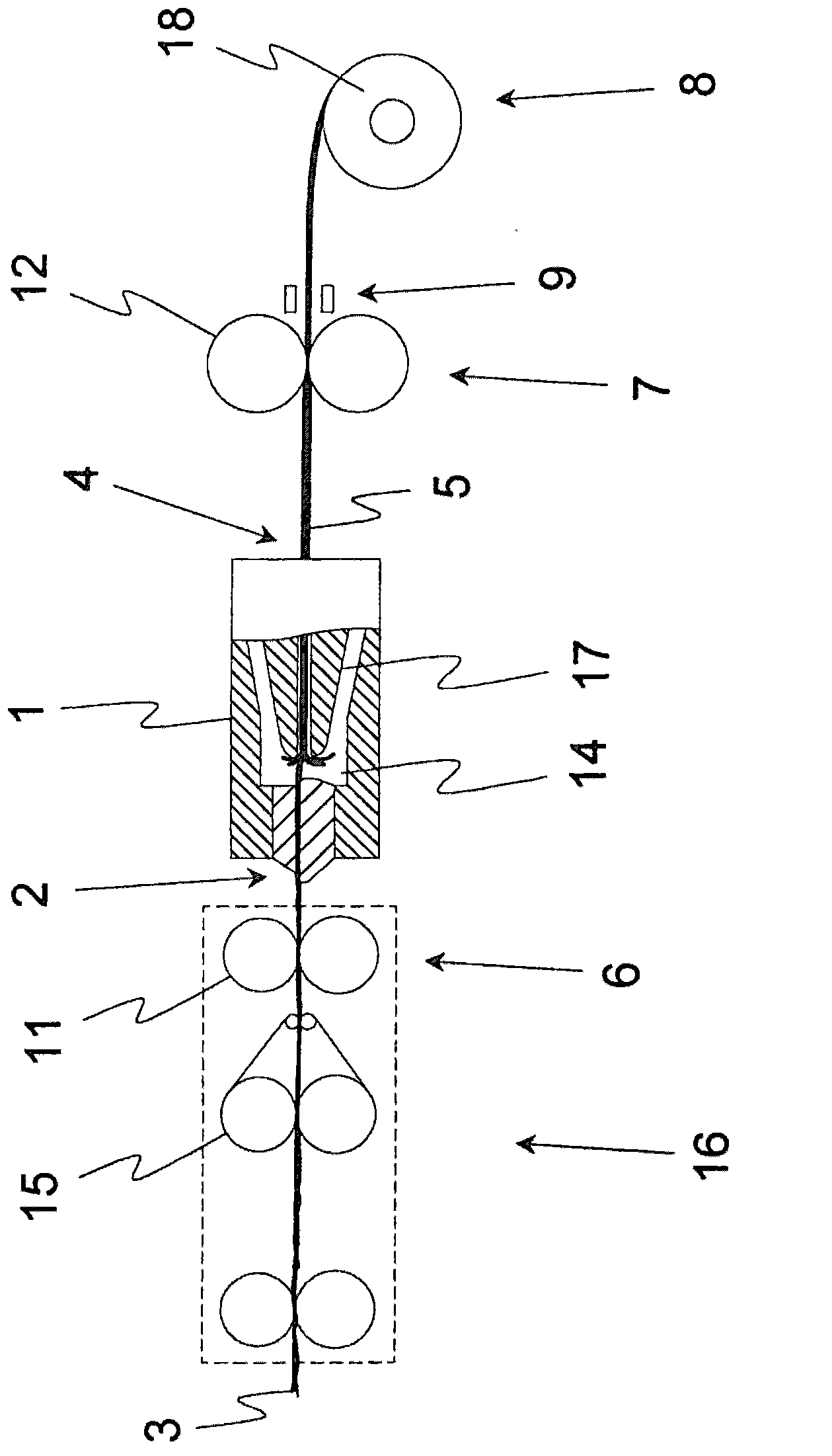

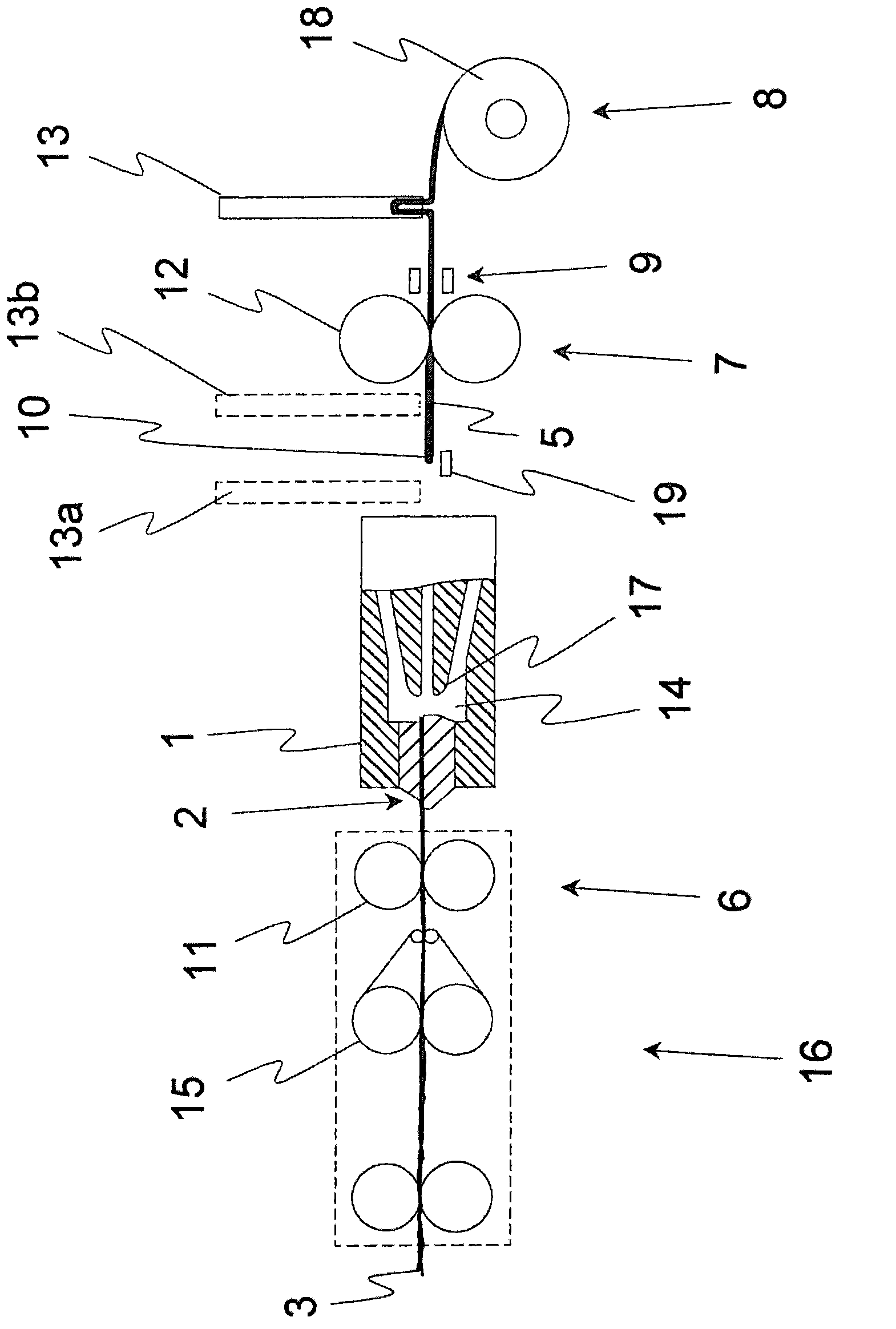

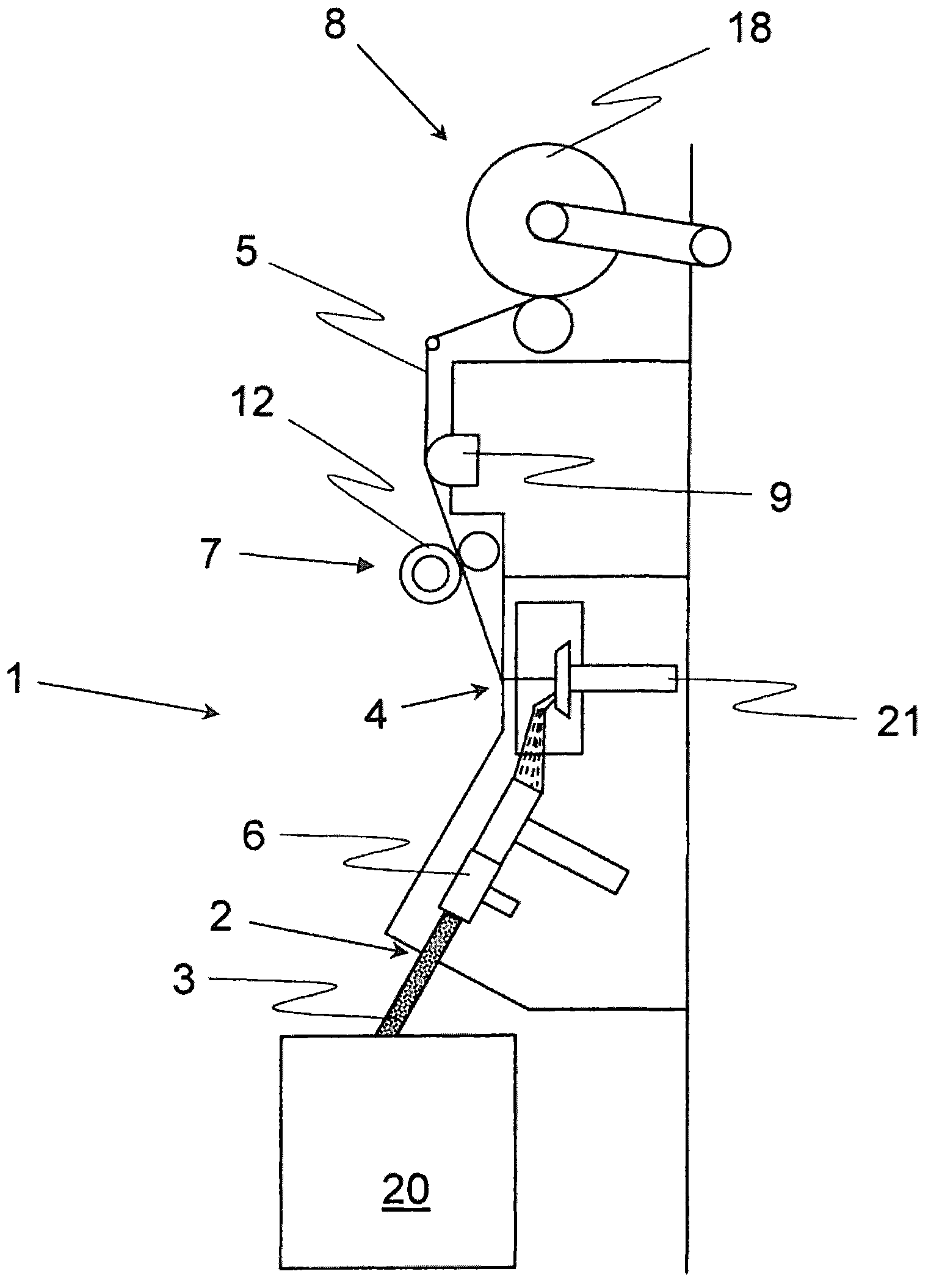

[0035] in figure 1 Shows a schematic cross-sectional view of the dry spinning machine according to the present invention. In the example shown, the dry spinning machine comprises a drafting device 16 which conveys the fibrous material 3, for example in the form of a doublierten. In addition, the dry spinning machine shown has a spinning station 1 separated from the drafting device 16 with an input end 2 for the fiber material 3 and an air vortex chamber 14 located inside. By means of a conveying device 6 configured to convey a pair of rollers 11 to guide the fiber material to the spinning station 1, the conveying device 6 can be turned to be part of the drafting device 16.

[0036] Finally, within the air vortex chamber 14, the fibrous material 3 or at least a part of the fibers of the fibrous material 3 is provided for manufacturing the desired yarn 5 by rotation. In this case, the rotation is generated by a targeted air flow in the area of the spindle 17, wherein the air flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com