A simulation test device for the concentration and return of impurities in steam generators of nuclear power plants

A steam generator and simulation test technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of huge energy consumption and low efficiency, and achieve precise temperature control, fast heating rate, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Gap impurity concentration experiment

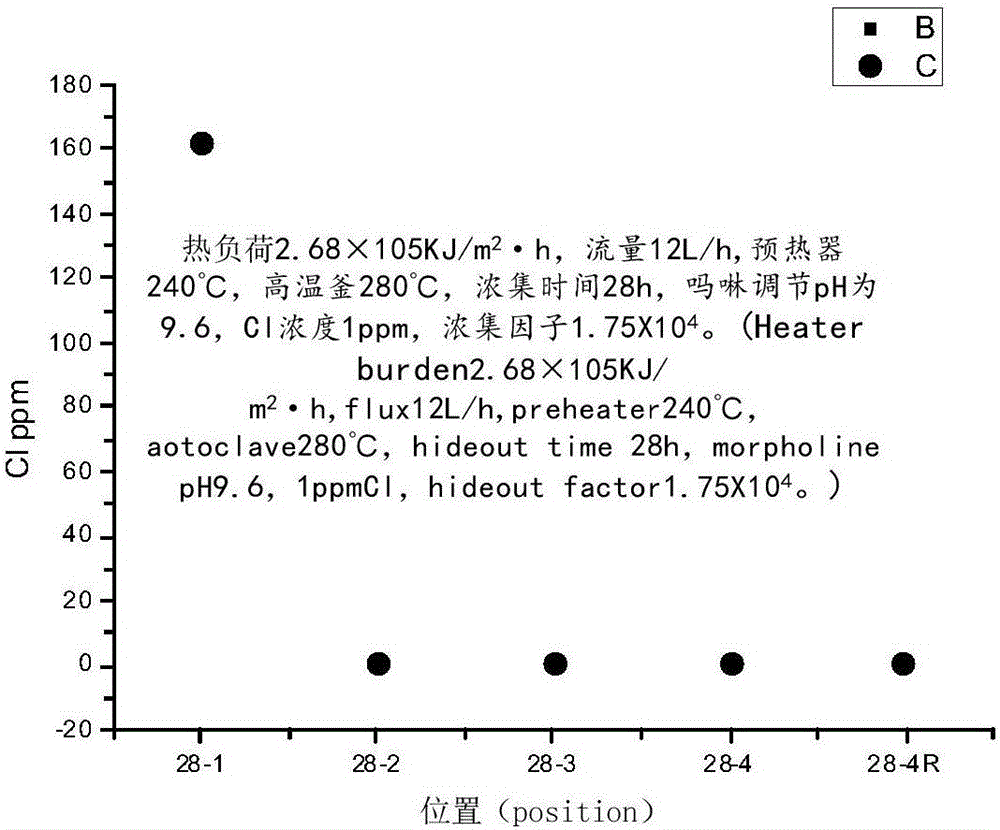

[0051] see figure 2 As shown in Table 1, it is a comparison chart / table of chloride ion concentrations in various parts of the circuit after 28 hours of concentration. When the stroke of the precision plunger pump is 20%, the flow rate is 12L / h, and the heat load is 2.68×105KJ / m 2 h. The temperatures of the preheater and the autoclave were 240°C and 280°C respectively, the pH was adjusted by morpholine to 9.6, and the chloride ion concentration of the bulk solution was 1mg / L. After 28 hours of concentration, the concentration factor is 1.75×10 4 times.

[0052] figure 2 In the middle abscissa, 28-1 refers to the concentration of impurity ions in the No. 1 (gap) sampling bottle after concentration for 28 hours, 28-2 is the concentration of impurity ions in the autoclave, 28-3 is the concentration of impurity ions in the sampling tank, 28- 4 is the concentration of impurity ions in the large water tank, and 28-4R ...

Embodiment 2

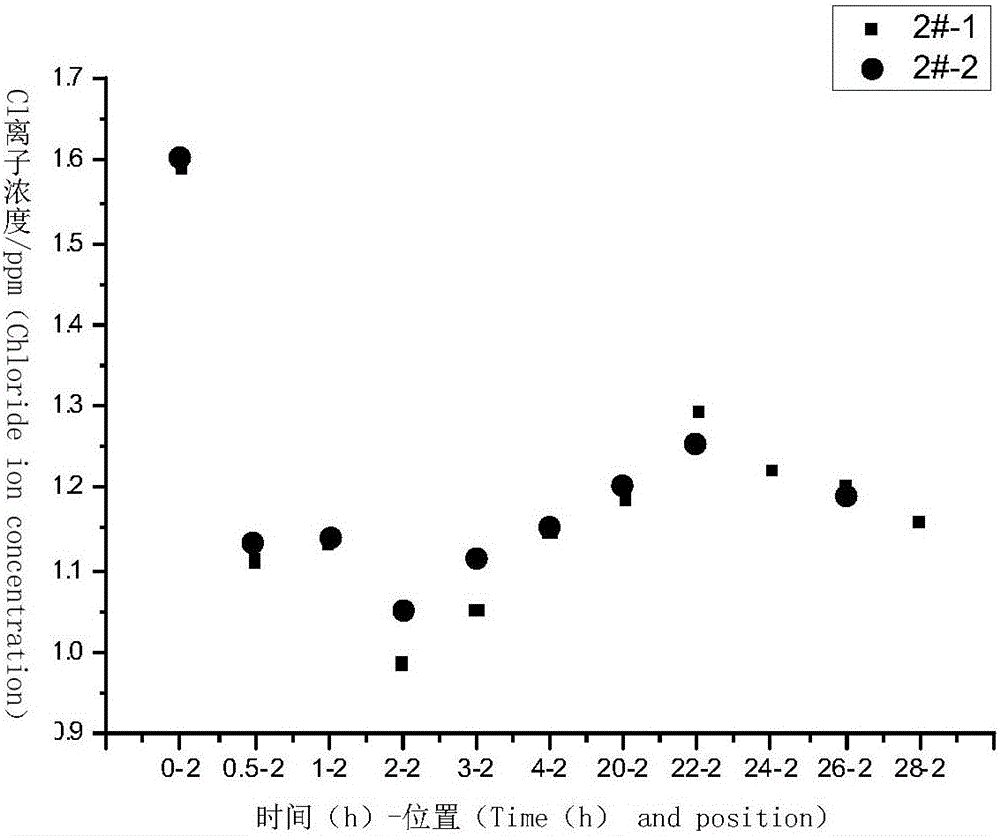

[0056] Example 2: Gap impurity return experiment

[0057] The working conditions of the experimental device for the preparation of the impurity return sample are: the pump stroke is 30%, the flow rate is 19.8L / h, the temperature of the preheater is 240°C, the temperature of the autoclave is 280°C, and the heat load of the experimental section is 2.49× 105KJ / m 2 h. The pH value was adjusted to 9.6 with morpholine, the concentration time was 24 hours, and the concentration factor was 2.67×10 4 times. After 24 hours of enrichment, the power supply of the experimental section was cut off immediately, and the temperature settings of the preheater and autoclave were lowered to 180°C (simulated reactor shutdown). Figure 3-6 In or shown in Table 2-5, 0h is the change of chloride ion concentration after the heating of the experimental section is stopped, and the preheater and autoclave are set at 180°C. 0.5h is the first rapid pressure change (4MPa-0.1MPa-4MPa), 5 seconds for pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com