Pebble-bed module type high-temperature gas cooled reactor fuel loading and unloading system

A technology for a high temperature gas-cooled reactor and a loading and unloading system, which is applied in the field of reactor engineering, can solve the complex structure of the crushed ball separator, the difficulty of protecting personnel in the isolation and maintenance of the radioactive atmosphere, and the safety isolation and pipe break protection of commercial nuclear power plants. Maintenance safety and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] In order to make the purpose, content, and advantages of the present invention clearer, the specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

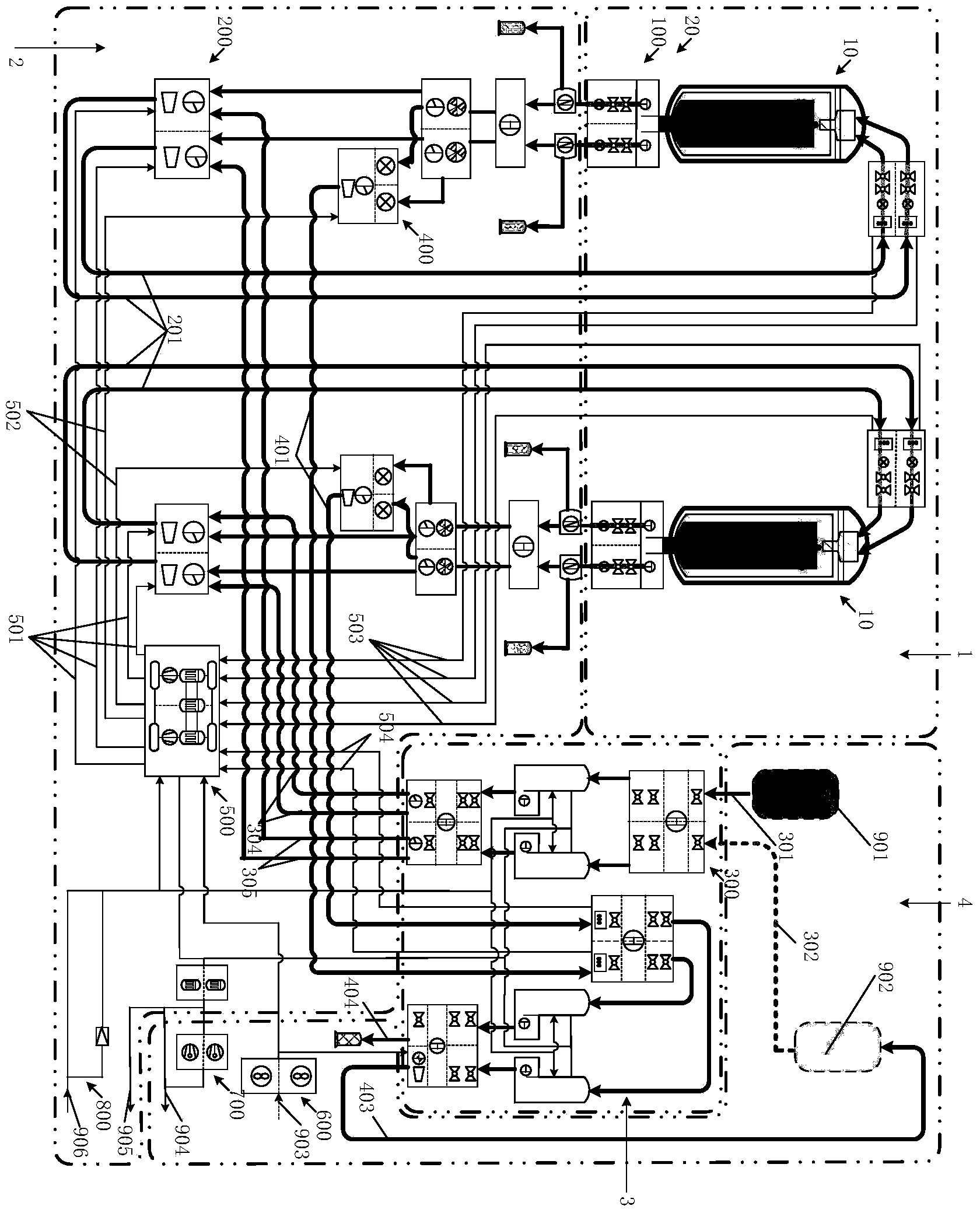

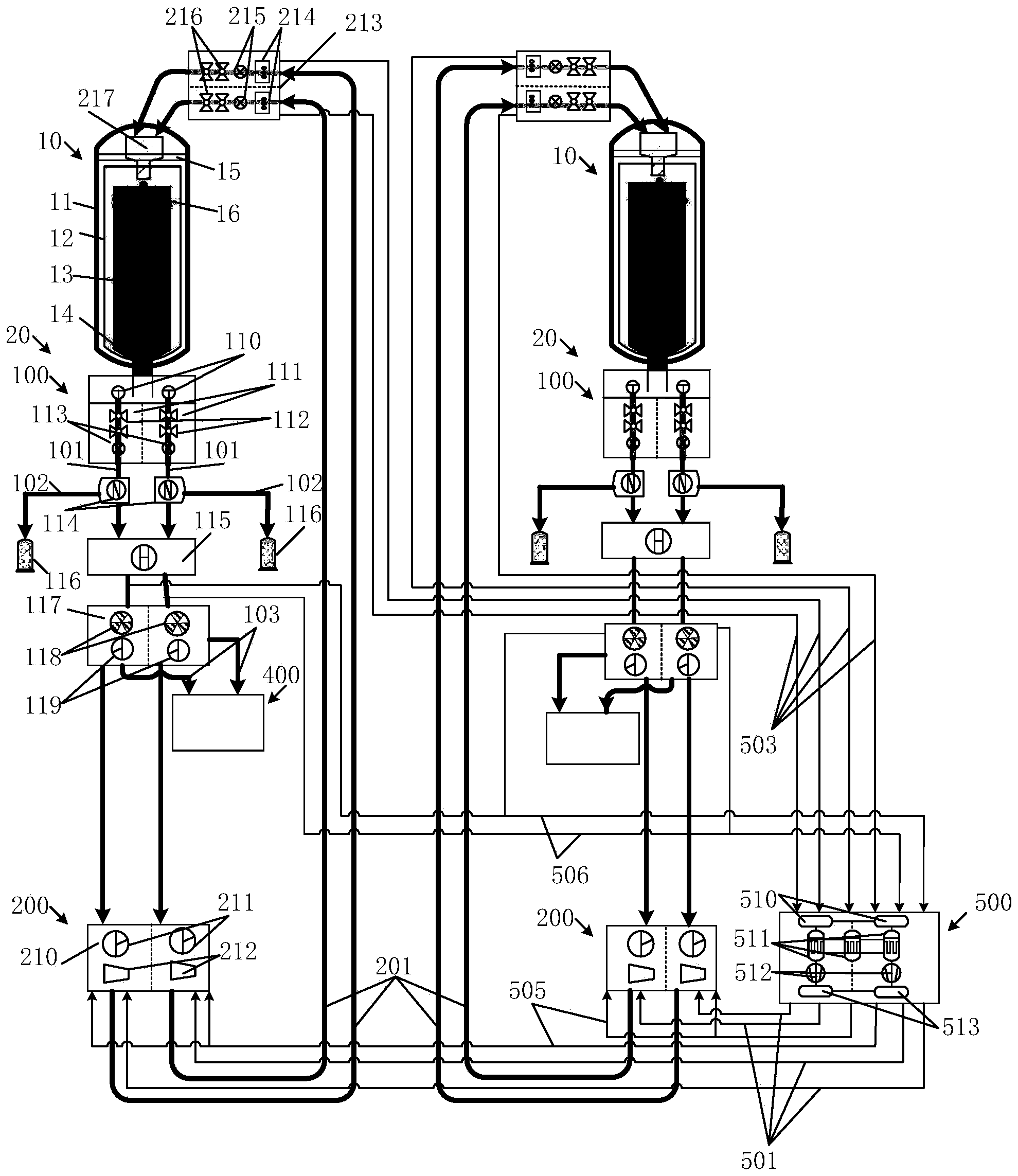

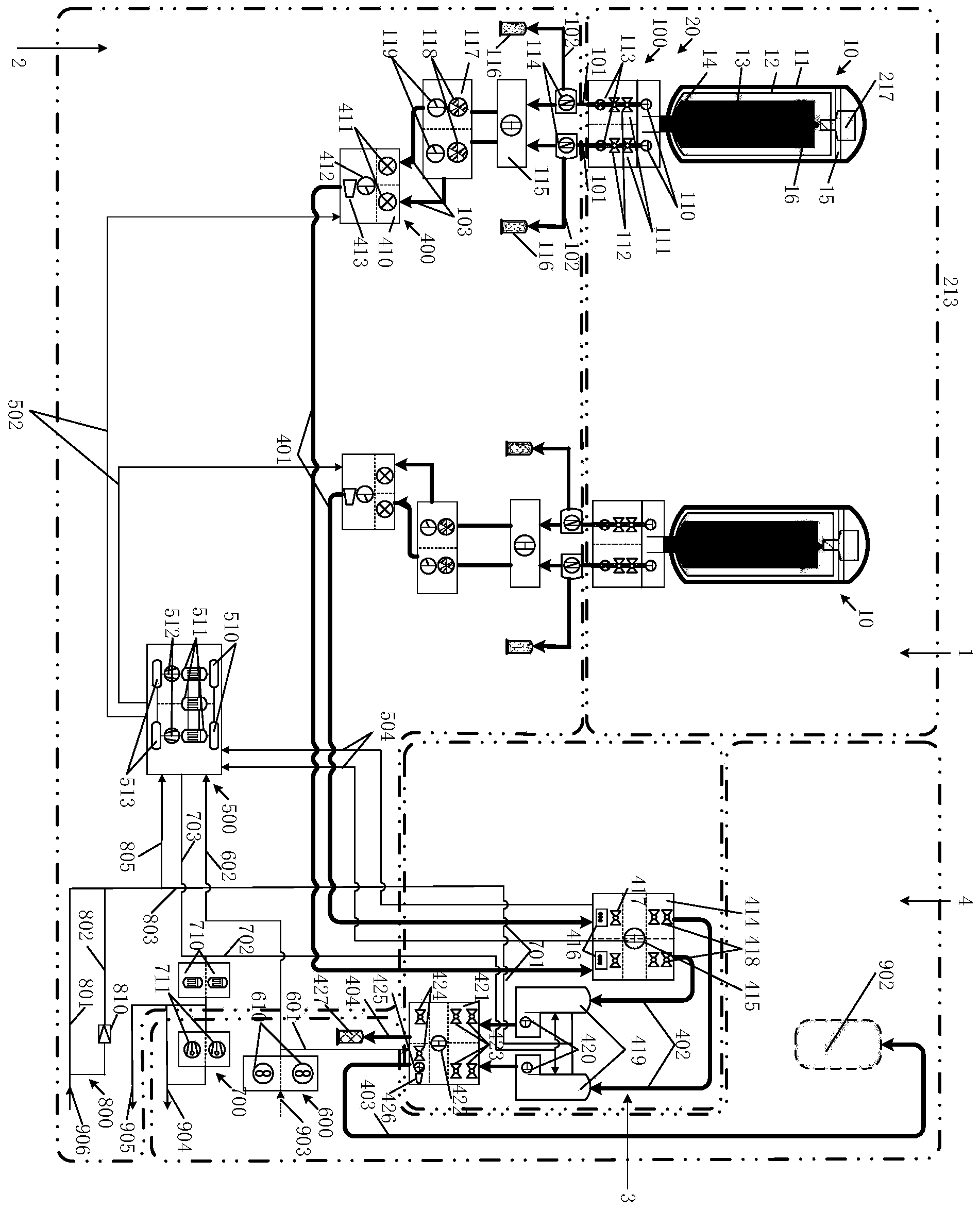

[0112] figure 1 It shows a general flow chart of an embodiment of the modular high temperature gas-cooled reactor involved in the present invention, Figures 2 to 4 The flow diagrams of the core fuel circulation system and its gas auxiliary system, the spent fuel unloading system and its gas auxiliary system, and the fresh fuel charging system and its gas auxiliary system of this embodiment are respectively shown.

[0113] The pebble bed modular high temperature gas-cooled reactor fuel loading and unloading system of the present invention is mainly divided into four parts, namely: a reactor 10 , a core fuel circulation system 20 , a new fuel charging system 300 and a spent fuel unloading system 400 . The fuel cycle system 20 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com