Arm driving device and robot used for industrial

A technology of industrial robots and driving devices, applied in the direction of claw arms, manipulators, manufacturing tools, etc., can solve the problems of motor installation with higher power, difficulty in improving motion accuracy, and inability to make the frame structure of the arm thicker, etc., to achieve The effect of increasing the conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the best mode for carrying out the present invention will be described with reference to the drawings. The arm driving device and the industrial robot of the present invention are not limited to the following description and drawings insofar as they have their technical features.

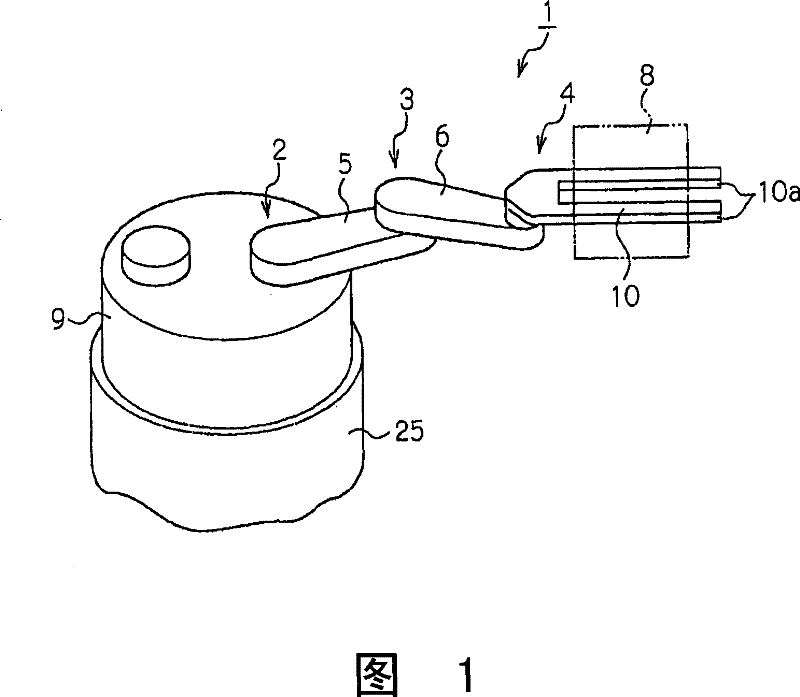

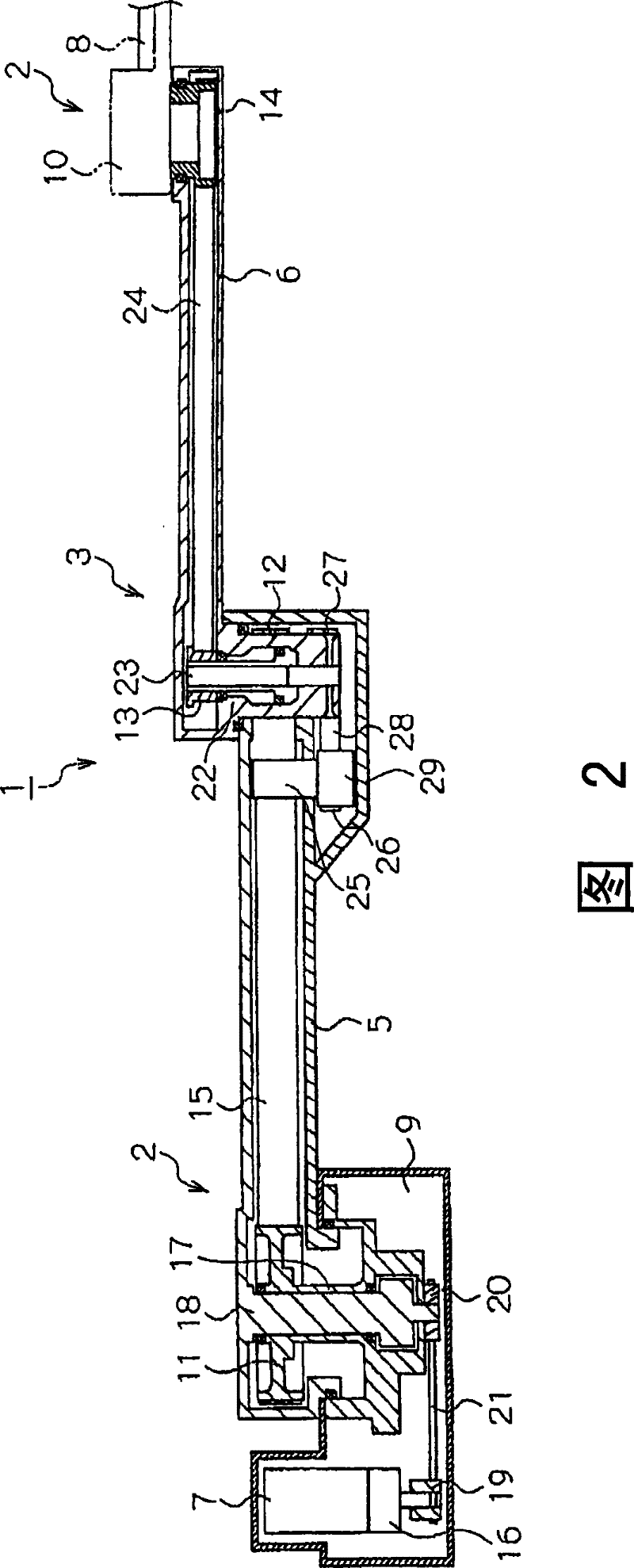

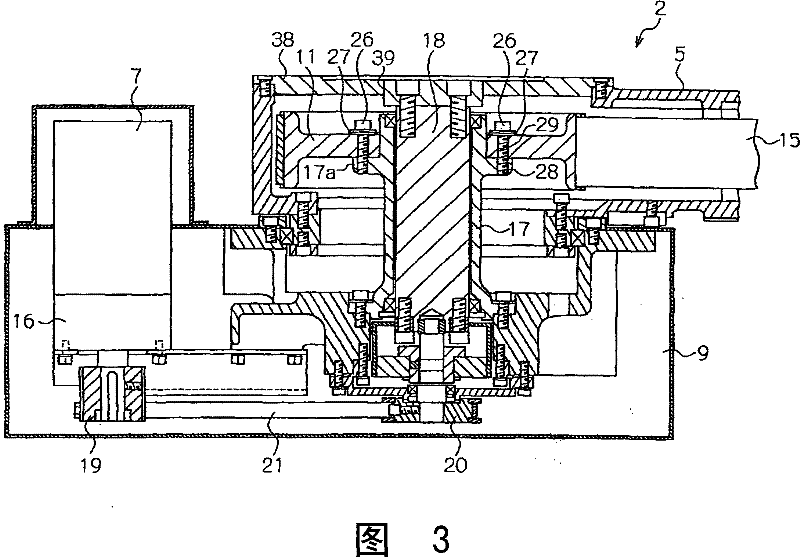

[0033] figure 1 It is a perspective view which shows an example of the industrial robot of this invention. Industrial robot of the present invention such as figure 1 As shown, there is an arm driving device 1 for telescopically moving a plurality of arm parts 5 , 6 , 10 connected by joint parts 2 , 3 , 4 . The telescopic movement of the first to third arm parts 5, 6 and 10 is transmitted to the first arm part 5 and the second arm part 5 and the second joint part 3 through one or both of the first joint part 2 and the second joint part 3 respectively. A total of two or more driving sources of the arm portion 6 are performed. An industrial robot having such an arm drive device 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com