A kind of fast arc cutting method

A rapid cutting and cutting method technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of frequent lifting of the cutting head, time-consuming and labor-consuming, and reduced processing efficiency of machine tools, so as to save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings.

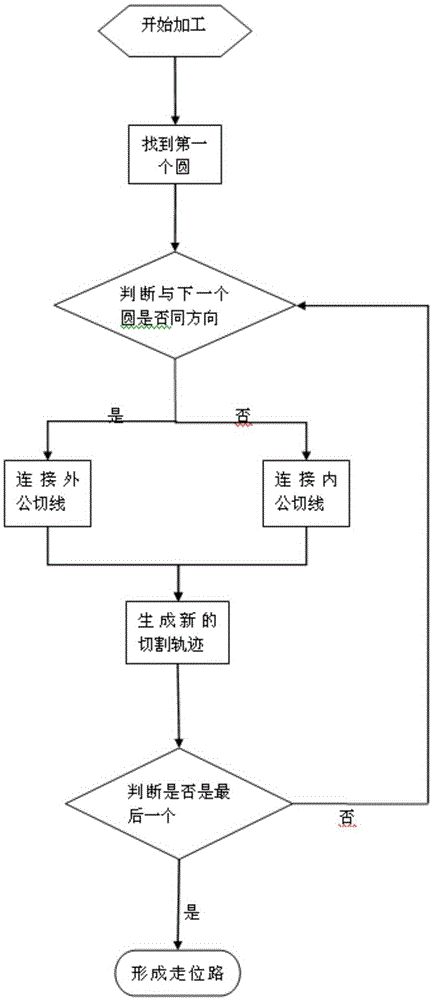

[0014] Such as figure 1 As shown, the cutting method of the present invention is a series of circles for the object, and the cutting method comprises the following steps:

[0015] (1) Start processing and start the processing software of the laser cutting machine;

[0016] (2) Laser cutting is performed from the first circle, and the position of the first circle is preset;

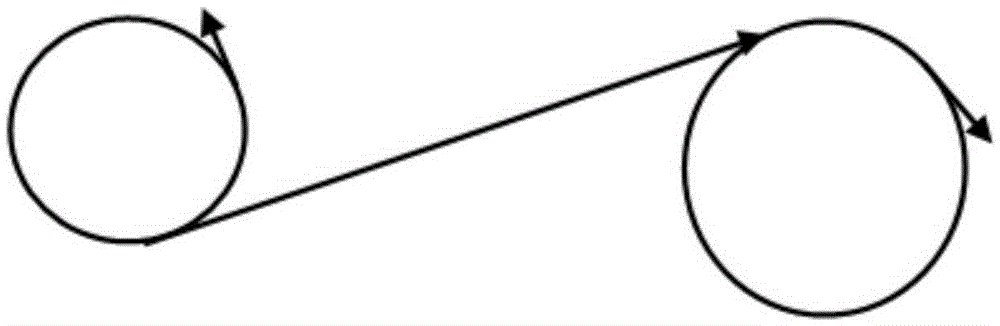

[0017] (3) After the first circle is laser cut, judge the positional relationship between the next circle and the current circle, whether they are in the same direction, if yes, connect the outer co-tangent line to find the next circle, otherwise connect the inner co-tangent line to find the next circle, The information contained in the circle is the center, radius and cutting direction, and the cutting direction is preset;

[0018] Determine whether it is clockwise or counterclockwise with the next ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com