Intelligent self-loading and unloading-type garbage compression truck

A garbage compression, self-loading and unloading technology, used in garbage storage, transportation and packaging, etc., can solve the problems of inability to collect the load of garbage cans, no load cell installed, sewage leakage, etc., to shorten the feeding stroke and feeding. time, improve garbage collection efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described with reference to the accompanying drawings.

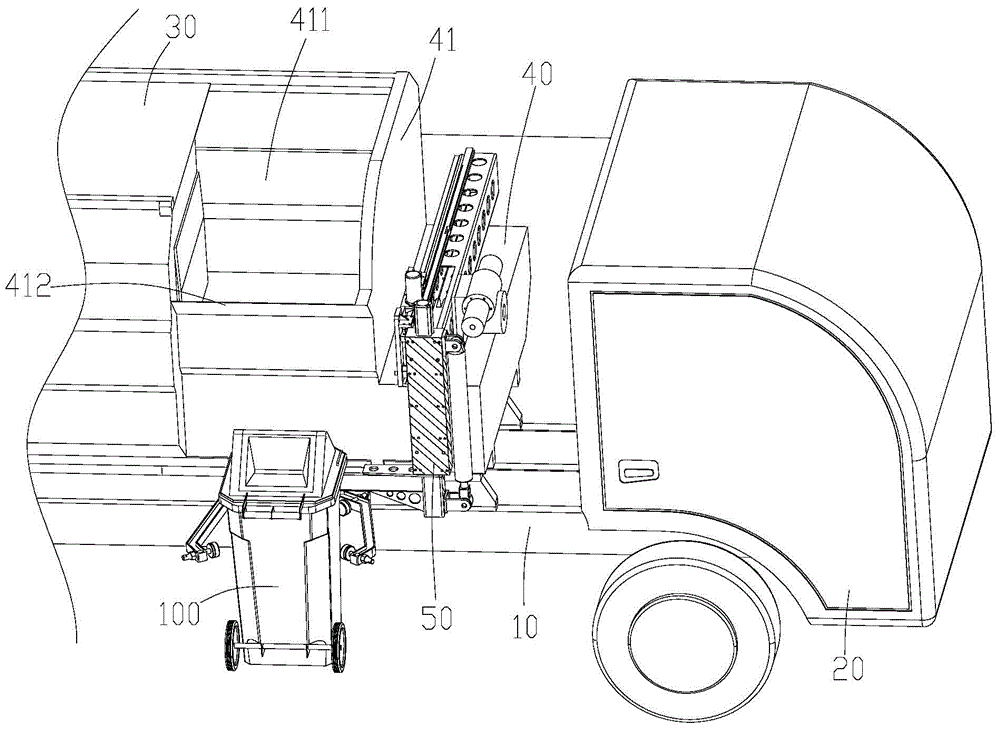

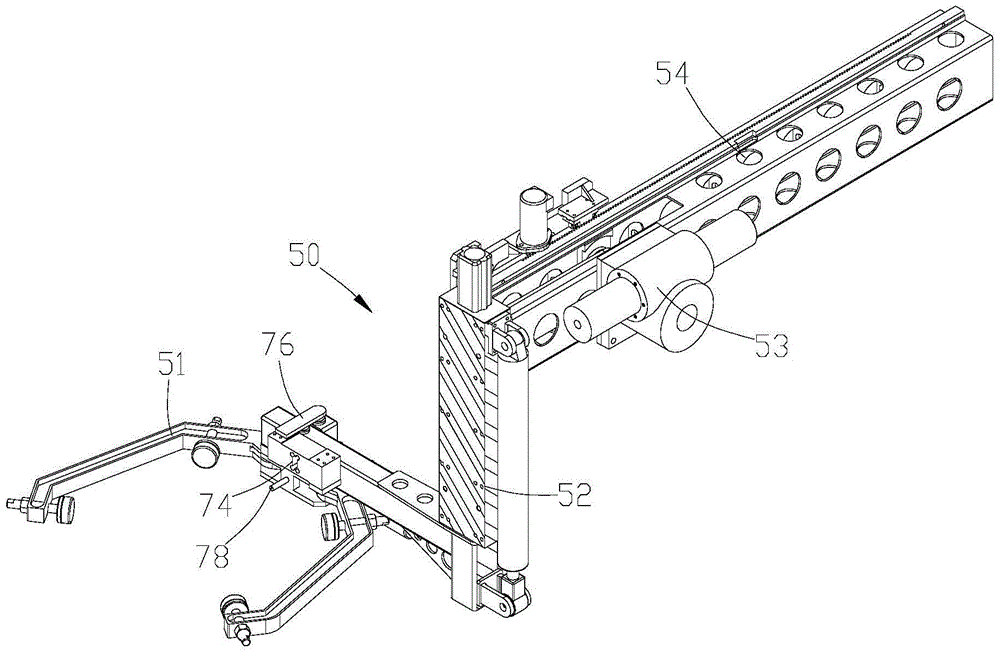

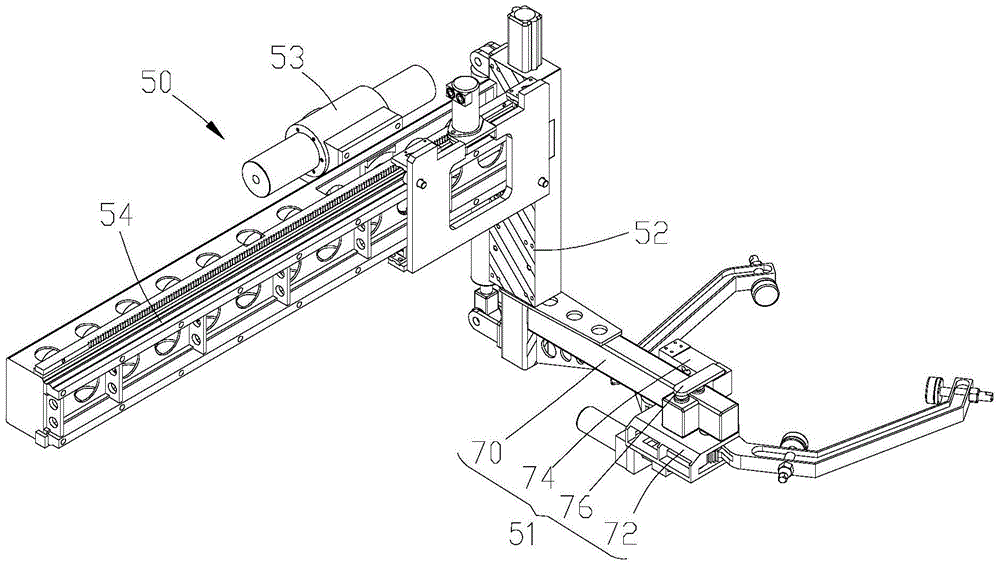

[0038] The invention provides an intelligent self-loading and unloading garbage compression truck. Please refer to Figure 1 to Figure 15 In an embodiment of the present invention, the intelligent self-loading and unloading garbage compression truck includes a frame 10, a front end 20 mounted on the front end of the frame 10, a car box 30 and a stuffing box 40 mounted on the frame 10, and The stuffing box 40 is located between the vehicle box 30 and the vehicle head 20 and communicates with the front end of the vehicle box 30. The intelligent self-loading and unloading garbage compression truck also includes an intelligent manipulator 50 and a sewage collection device 60. A feed frame 41 is arranged above the stuffing box 40, and the bottom of the feed frame 41 is communicated with the stuffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com