Portable steel tube inner wall de-rusting vehicle

A portable technology for the inner wall of a steel pipe, applied in metal processing equipment, manufacturing tools, grinders, etc., can solve problems such as affecting the overall quality, inability to remove rust, and inability to ensure safe use, etc., to avoid environmental pollution, good use effect, and prevent dust floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

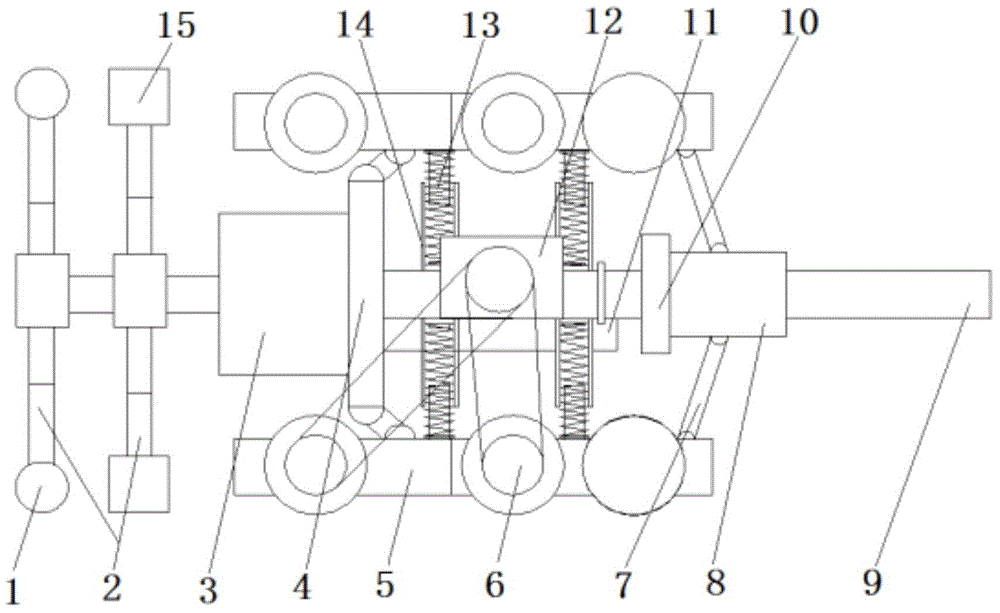

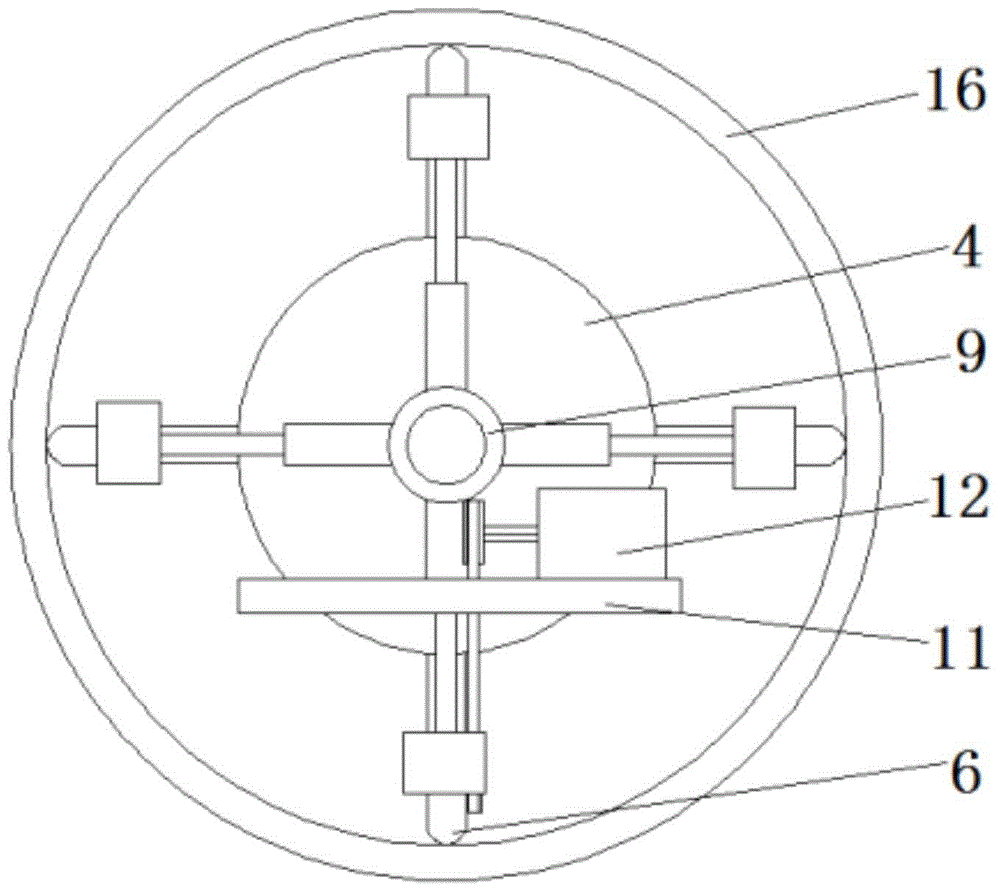

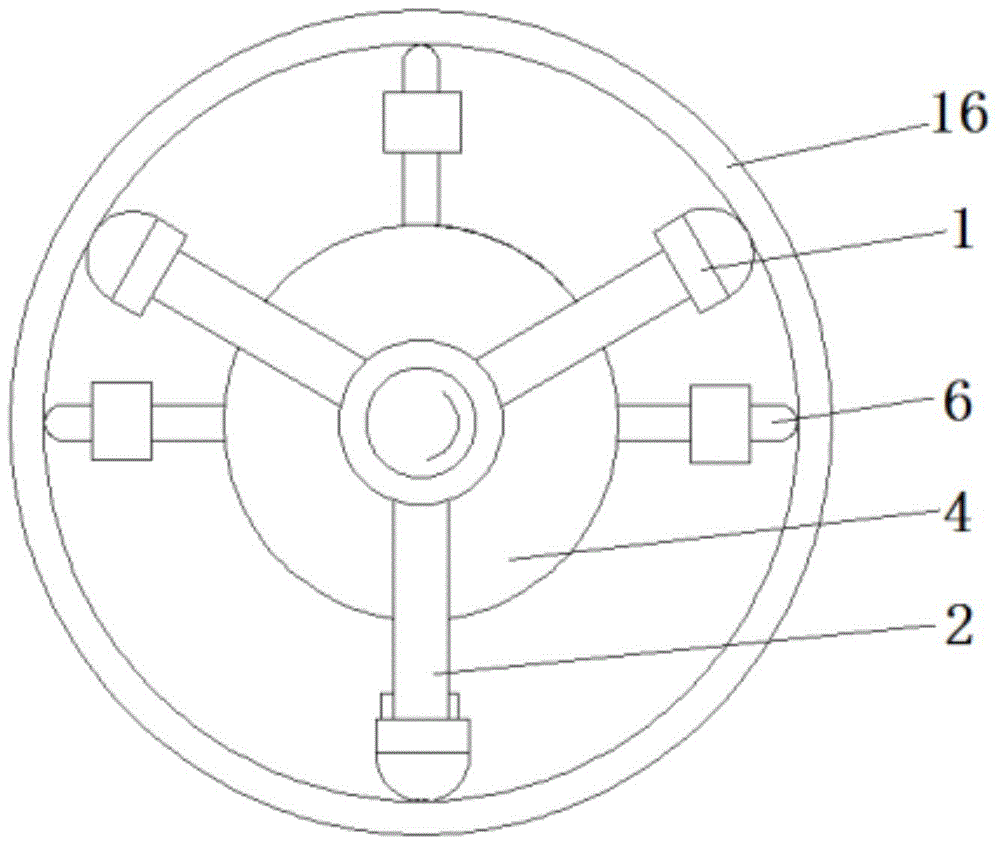

[0014] A portable steel pipe inner wall derusting car, including a frame 4, the two sides of the frame 4 are respectively fixed with a derusting motor 3 and a central shaft 9, and the motor shaft of the derusting motor 3 is provided with two layers of brackets 2 , each layer has three equally divided brackets 2, a steel wire wheel 1 is provided on the bracket 2 near the front end to remove rust and dust on the inner wall of the steel pipe 16, and a polishing wheel 15 is provided on the bracket 2 of the second layer for cleaning. Restoring the polishing process, a section of the shaft body close to the central axis 9 of the vehicle frame 4 is uniformly provided with a limit groove 14, and the other section of the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com