Paper high speed synchronization butt joint device for photogravure press units

A gravure printing machine, high-speed synchronization technology, used in printing machines, rotary printing machines, printing and other directions, can solve problems such as machine vibration, auxiliary machine damage, inability to enter auxiliary machines, etc., to achieve reliable structure, low manufacturing cost, and reliable guarantee. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they are not intended to limit the present invention.

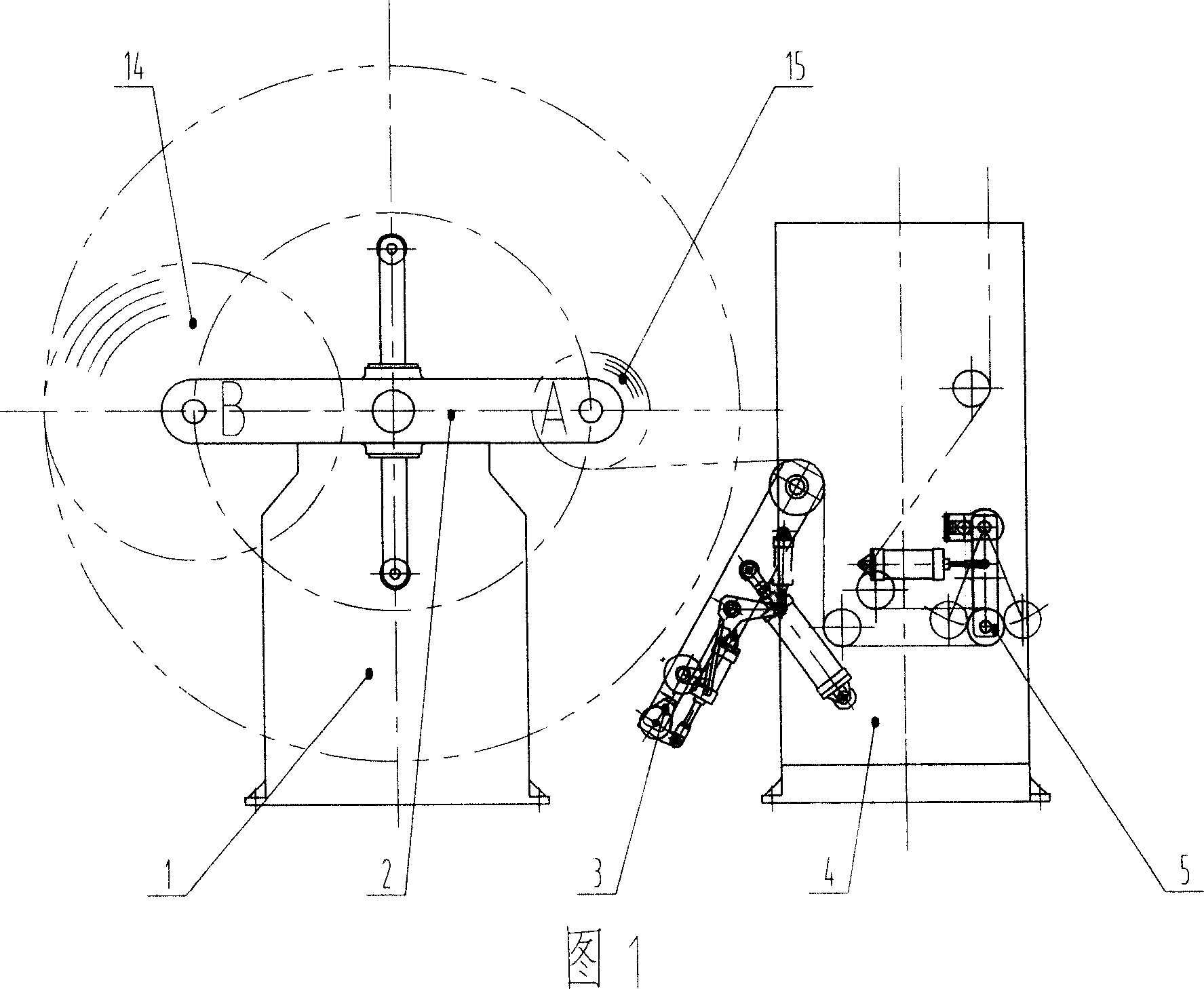

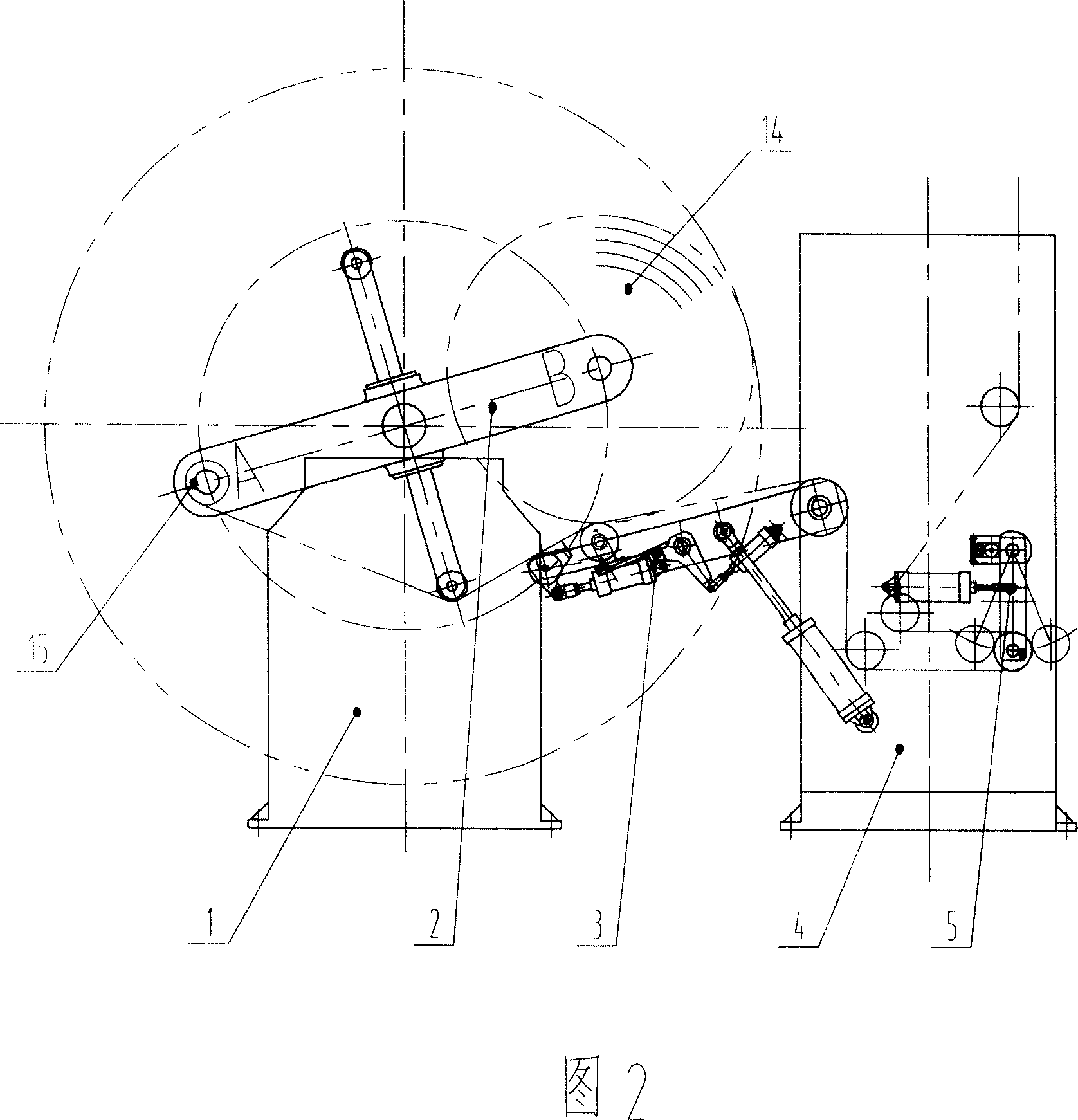

[0015] From Fig. 1 and Fig. 2, the material receiving in the prior art adopts the overlapping method, the rotary boom 2 is fixed on the rotary support 1, and the cutting knife mechanism 3 and the swing roller 5 are fixed on the frame 4. When receiving materials, the swivel arm 2 rotates clockwise so that the new material roll 14 is transferred to the receiving position, and the cutter mechanism 3 also arrives at the receiving position. When the linear velocity of new material roll 14 loading is identical with old material roll 15 linear speeds, cutting knife mechanism 3 earlier sticks together new and old material with adhesive tape, and then old material is cut off, and lap is completed.

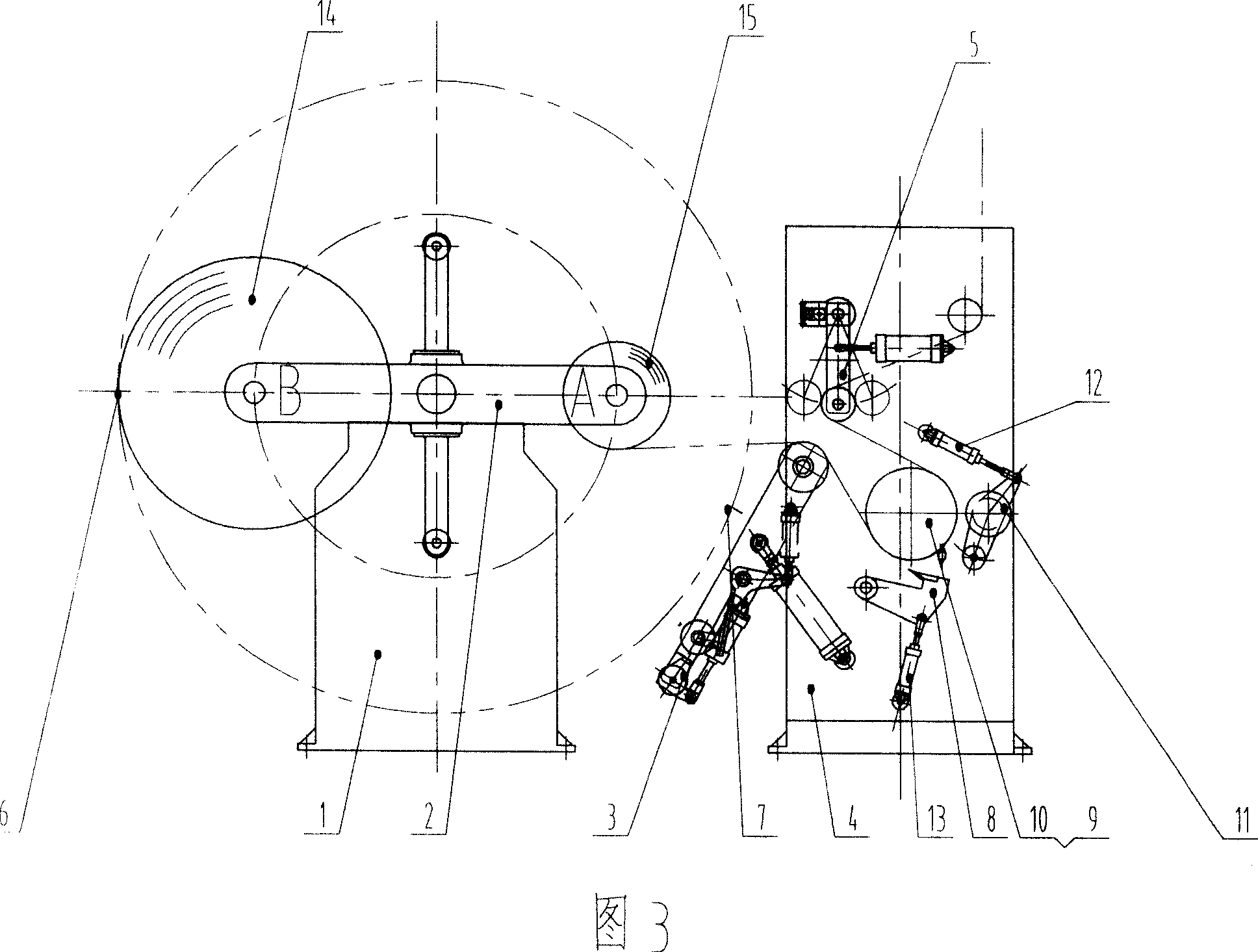

[0016] In Fig. 3 and Fig. 4, the slewing arm 2 is fixed on the slewing support 1, the cutter mechanism 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com