Welding method of Q890 high-strength steel

A welding method and high-strength steel technology, applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., can solve the problems of increasing penetration depth, high welding cost and incapable of industrial production, and achieve the prevention of welding cold cracks, Improved welding efficiency and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

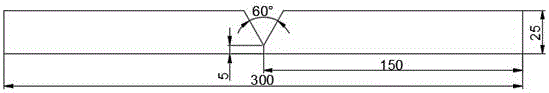

[0015] 1. Process the test plate: such as figure 2 As shown, the test plate is 150mm wide, 350mm long, δ=25mm thick, with a blunt V-shaped groove α=60°, and blunt side p=5mm.

[0016] 2. Clean the groove: clean the 30mm inner surface on both sides of the groove.

[0017] 3. The welding material is selected as 90KG welding wire, and the shielding gas is 80%Ar+20%CO 2 .

[0018] 4. Preheat the assembled parts to be welded to 80°C.

[0019] 5. Apply laser-arc hybrid welding:

[0020] ① The workpiece to be welded is ground welded, the laser is in front, the MIG heat source is in the back, the laser power is 3.0KW, the current is 240A, the voltage is 25V, the distance between the light wires is 3mm, the defocus is 4mm, and the welding speed is 0.8cm / s.

[0021] ② Filler welding is performed on the workpiece to be welded, the laser is placed in front, the MIG heat source is placed behind, the laser power is 3.5KW, the current is 260A, the voltage is 28V, the distance between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com