Hybrid heat pump / refrigerator with magnetic cooling stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

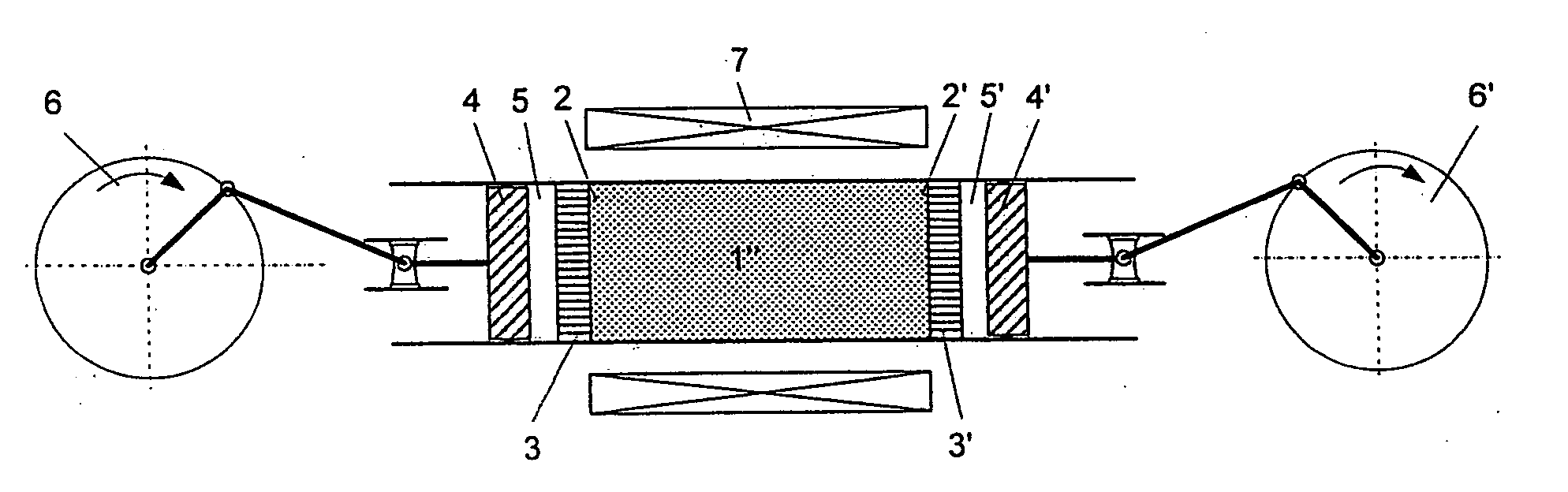

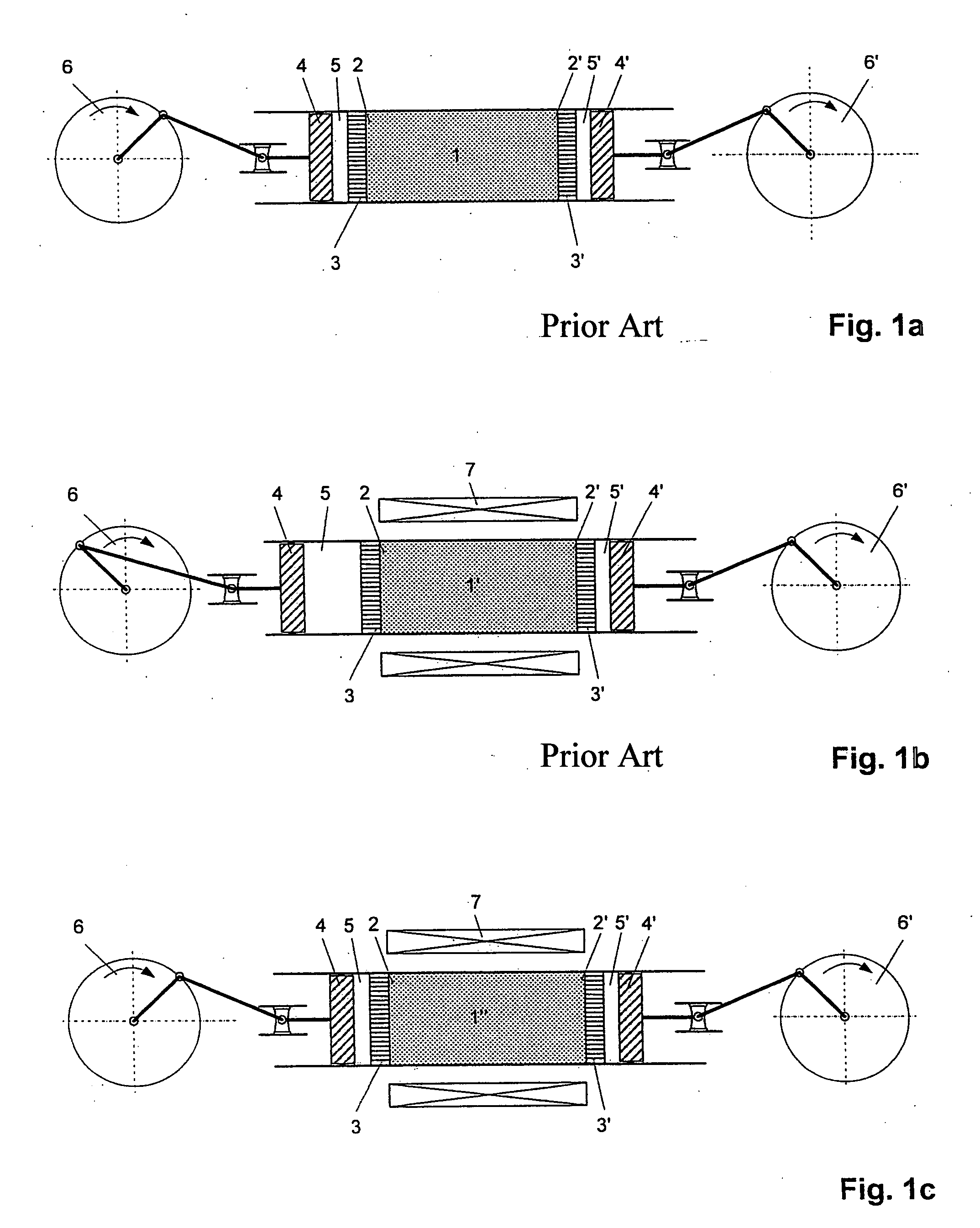

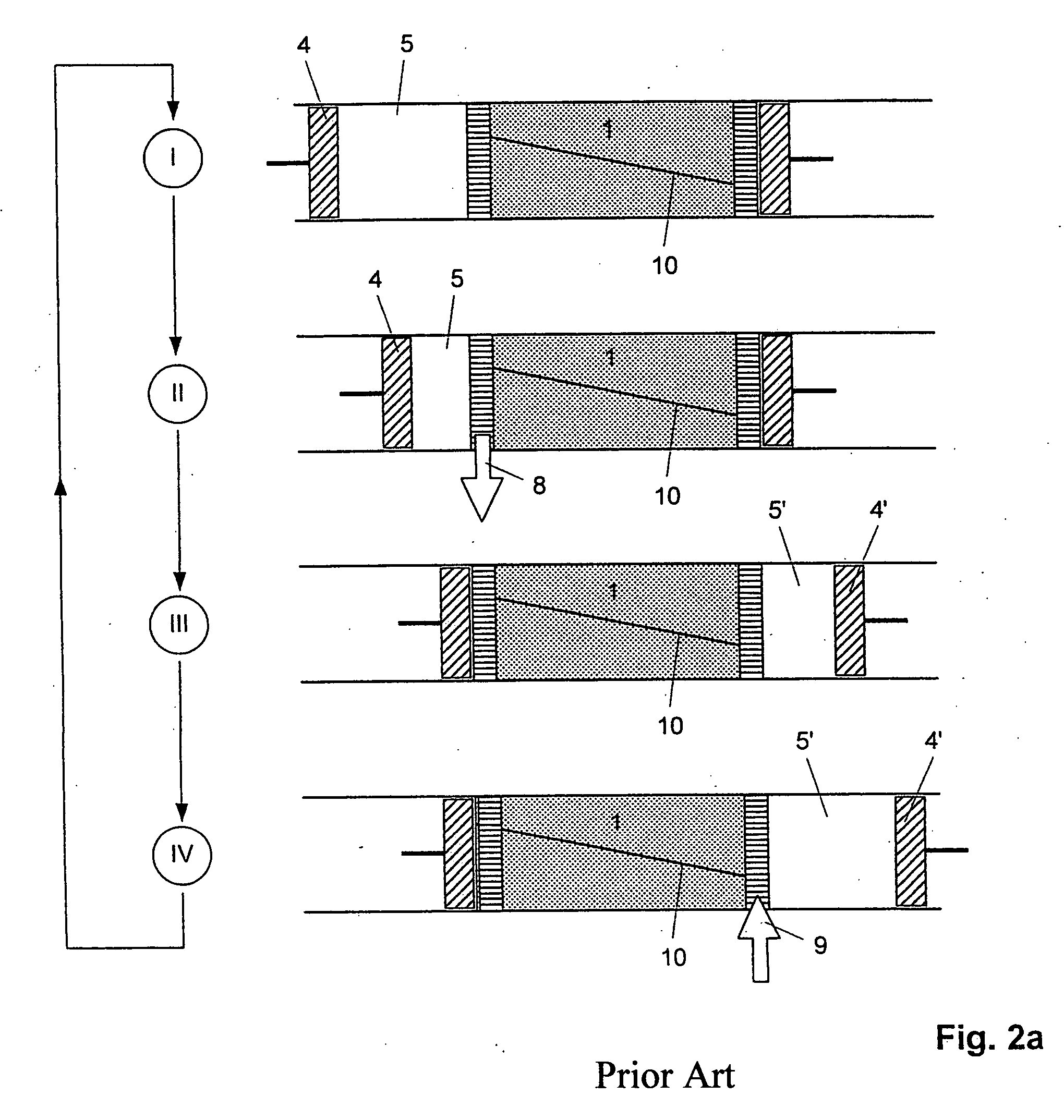

[0046]FIG. 1a schematically shows the structure of a (one-stage) regenerative Stirling gas refrigerator (or heat pump) according to prior art. The Stirling machine represents the basic form of all machines which are based on a regenerative cycle. The other gas refrigerators, such as Gifford-McMahon coolers or pulse tube coolers, are derived from this basic form.

[0047]The machine consists of a heat storage medium, a so-called (passive) regenerator 1 which is limited at its warm end 2 by a warm heat exchanger 3 (for a refrigerator approximately at ambient temperature) and is limited at its cold end 2′ by a cold heat exchanger 3′ (for a refrigerator below ambient temperature). The regenerator 1 consists of a finely distributed solid, e.g. in the form of woven metal screens or bulk particles, and has a high heat capacity compared to the working fluid, e.g. helium gas. The regenerator 1 absorbs heat from the working fluid during passage, and releases it after flow reversal to the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com