Combined gas-water tube hybrid heat exchanger

a technology of heat exchanger and water tube, which is applied in the field of heat exchanger, can solve the problems of increasing fabrication and installation costs, unnecessarily warm top casting, and failure to harness and recover the maximum amount of energy, and achieves the effect of simple and less costly construction techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

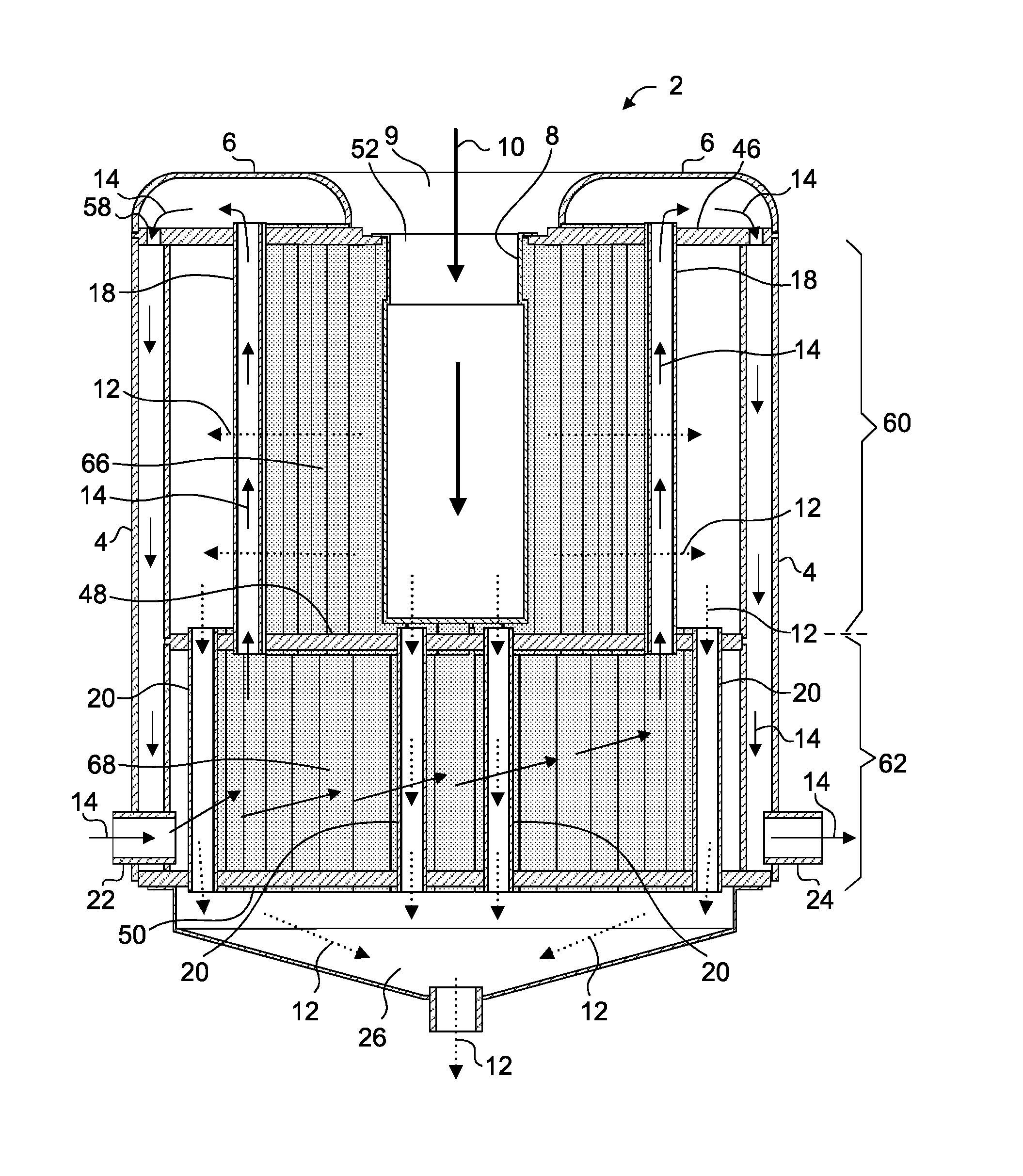

Embodiment Construction

[0036]The term “about” is used herein to mean approximately, roughly, around, or in the region of. When the term “about” is used in conjunction with a numerical range, it modifies that range by extending the boundaries above and below the numerical values set forth. In general, the term “about” is used herein to modify a numerical value above and below the stated value by a variance of 20 percent up or down (higher or lower).

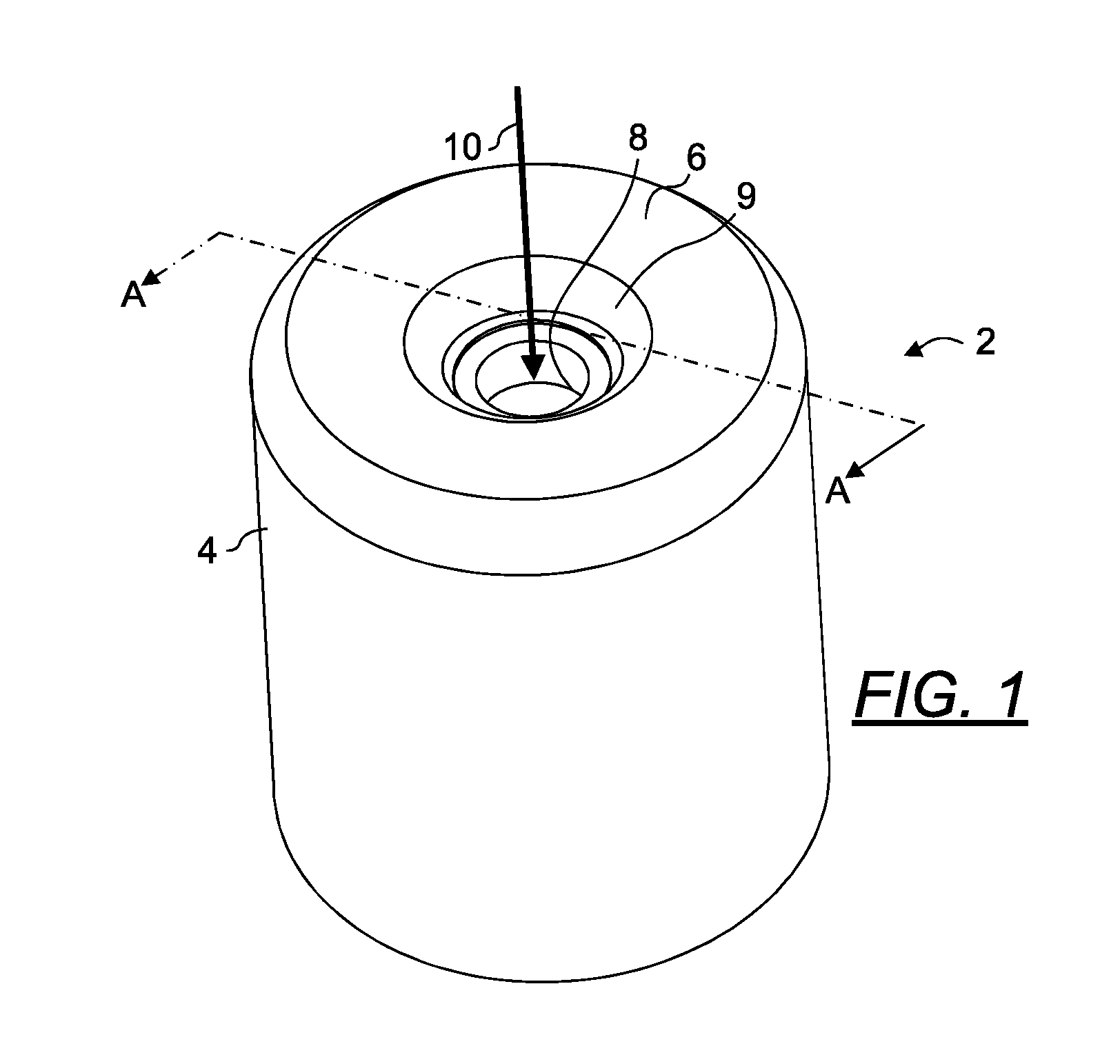

[0037]FIG. 1 is a top perspective view of a heat exchanger 2 of the present invention, depicting a cavity for receiving air / fuel mixture through the top surface of the heat exchanger 2. In use, an air / fuel mixture flow is provided in direction 10 to the burner 8 with the aid of a blower 28 (see FIG. 11). The external surfaces of the heat exchanger generally define an elongated cylindrical shaped body having a side water jacket 4, a top water jacket 6 and an opening 9 in the top water jacket 6.

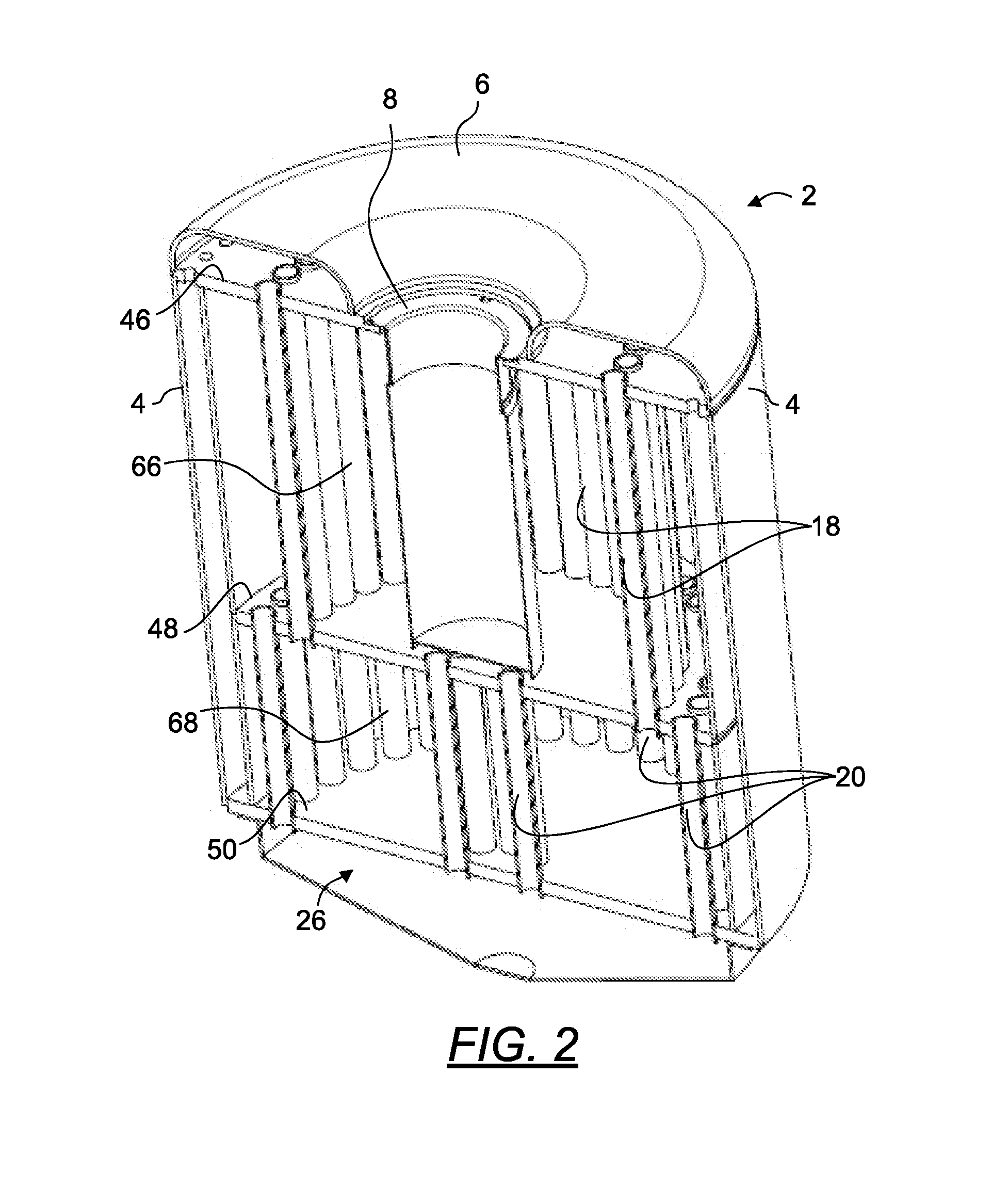

[0038]FIG. 2 is a top perspective sectional view as taken along line A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com