Non-catalytic partial oxidation gasification furnace of inferior raw material

A non-catalytic part, gasification furnace technology, applied in the field of gasification furnace, can solve the problems of short continuous operation period, short operation life and high furnace top temperature of gasification furnace, so as to solve the problem of carbon black and ash entrainment and prolong operation The effect of life and prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

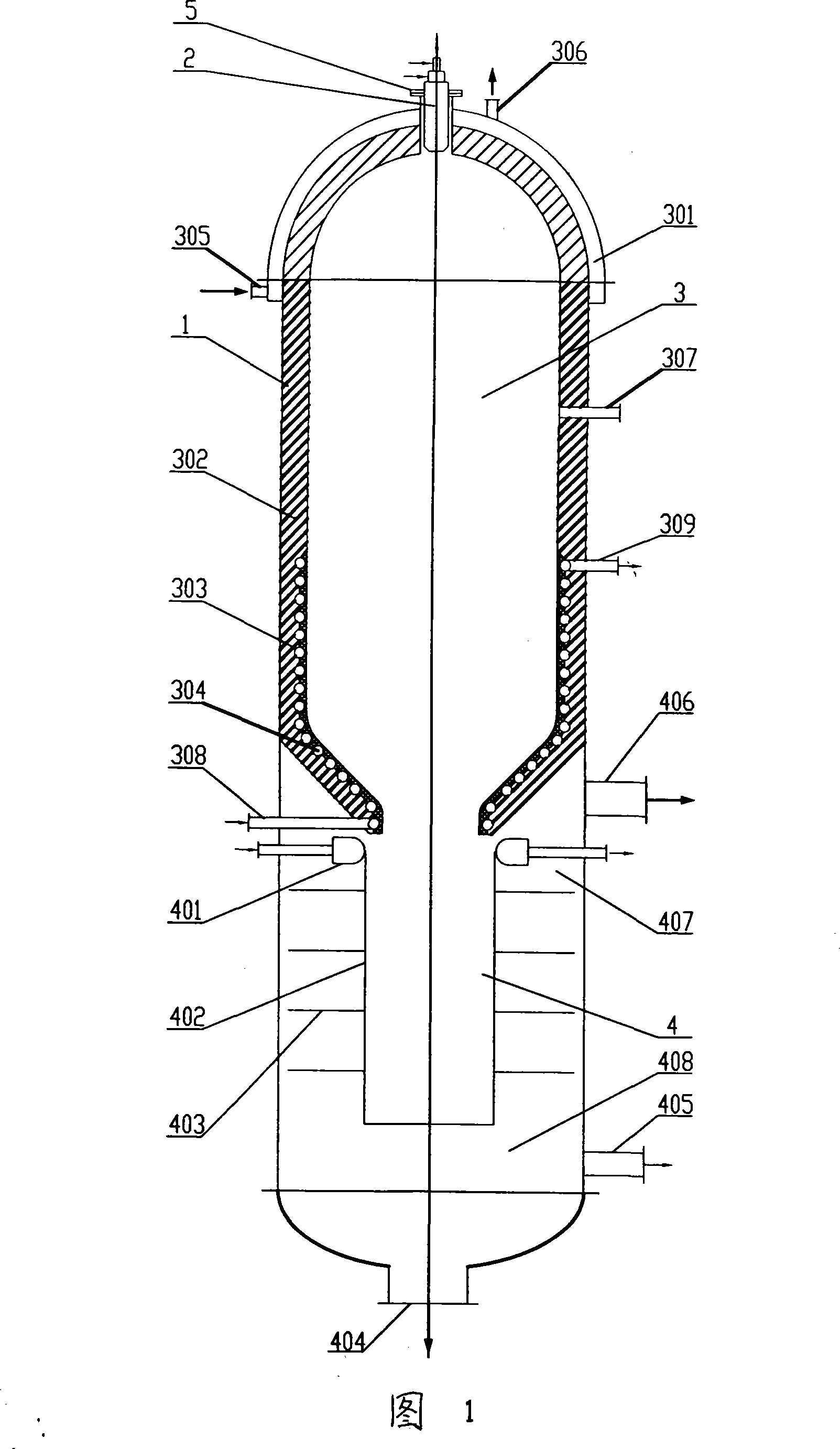

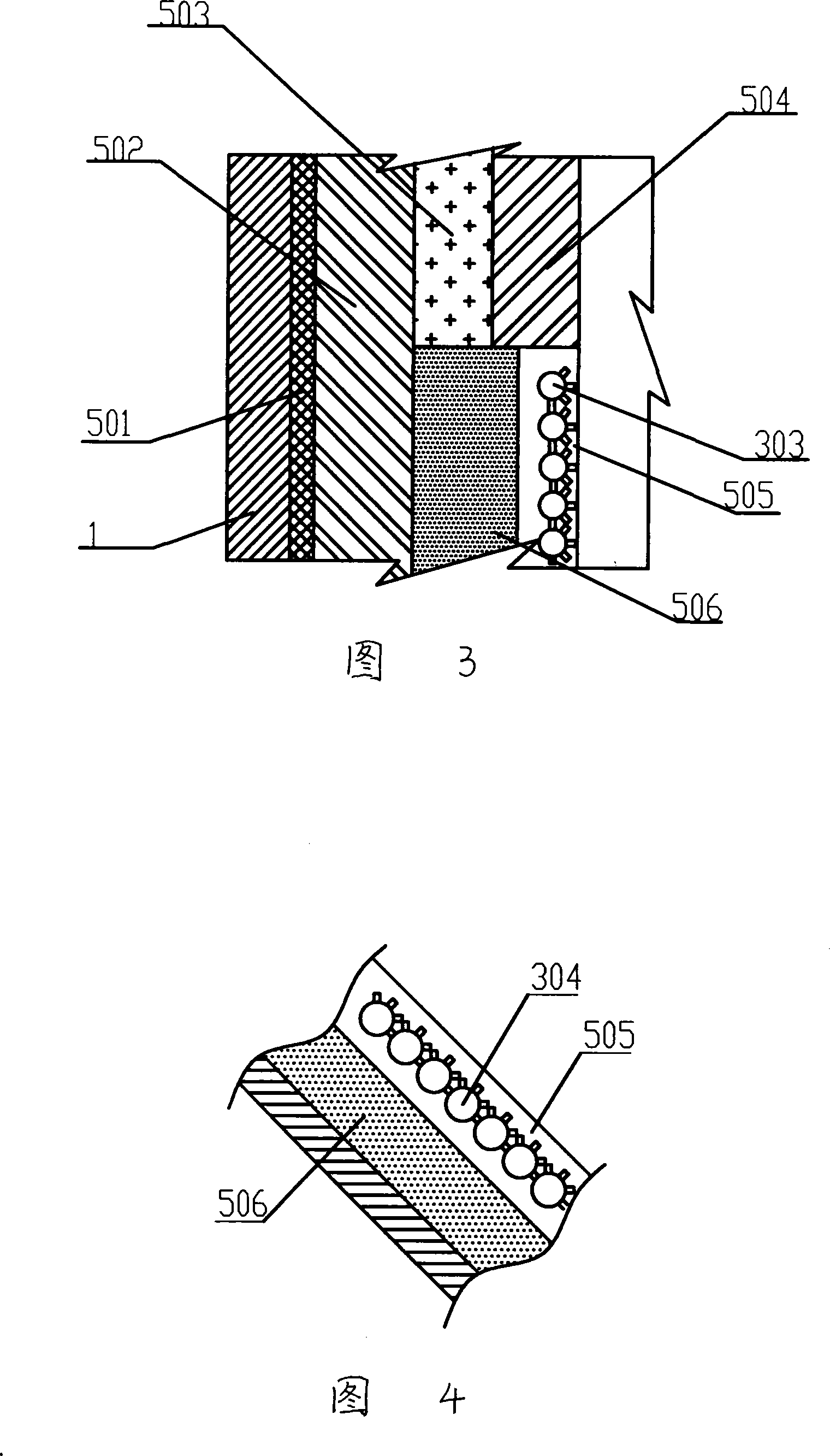

[0033] Embodiment 1: See Fig. 1, a non-catalytic partial oxidation gasifier for inferior raw materials, at least one nozzle 2 is arranged on the top of the gasification reactor chamber 3, the inner diameter of the gasifier shell is 2400 mm, and the inner diameter of the gasification furnace 1600mm in diameter. The gasification reaction chamber 3 communicates with the quenching and washing chamber 4, the gasification reaction chamber 3 is arranged on the upper part of the gasification furnace, and the height of its straight section is 6400 mm, and the quenching and washing chamber 4 is arranged on the lower part of the gasification furnace, and its height is 8500 mm , the gasification reaction chamber 3 and the chilling washing chamber 4 share a pressure-bearing cylinder 1, and the nozzle 2 is connected to the gasification reaction chamber 3 through a flange 5; the nozzle 2 is a multi-channel external mixing nozzle. The chilling and washing chamber 4 is arranged at the lower en...

Embodiment 2

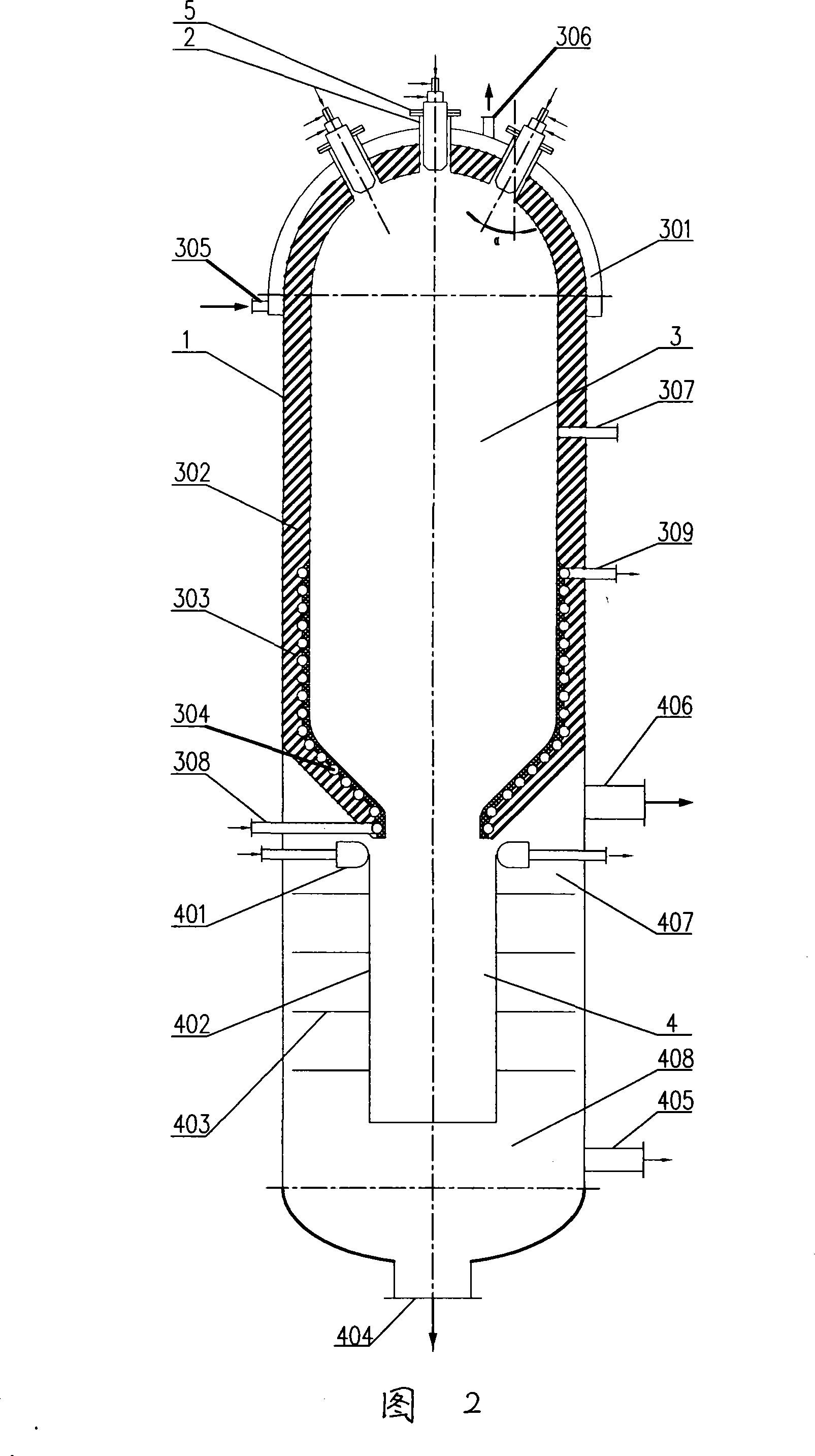

[0036] Example 2: A non-catalytic partial oxidation gasifier for inferior raw materials. The inner diameter of the shell of the gasifier is 2600 mm, and the inner diameter of the surface facing the fire is 1800 mm. The gasification reaction chamber 3 communicates with the quenching and washing chamber 4. The gasification reaction chamber 3 is arranged on the upper part of the gasification furnace with a height of 6000 mm, and the quenching and washing chamber 4 is arranged on the lower part of the gasification furnace at a height of 8000 mm. The chamber 3 and the chilling washing chamber 4 share a pressure-bearing cylinder 1, and there are three nozzles arranged on the top of the gasification reaction chamber 3, which are evenly arranged around the center of the top. The angle α is 30°. Three four-channel gasification nozzles 2 are arranged at equal intervals on the furnace roof, wherein oxygen enters the central flow channel and the third flow channel, water-coke slurry enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com