Laser Ultrasonic Determination Method of Metal Third-Order Elastic Constant

A technology of elastic constant and measurement method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems of elastic constant measurement error, easy misjudgment, error, etc., achieve high precision, improve measurement accuracy, and avoid axial The effect of length changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] We used the water bath heating method to conduct experiments on aluminum plate samples at two temperatures: room temperature 21°C-23°C and water boiling point temperature 100°C. In this range, there is no structural change in the aluminum sample, so there will be no error caused by the sample thickness caused by the application of axial stress. The sample is submerged to half its thickness in water, the temperature of which is measured by a thermocouple. The solution of the equation depends only on the difference in temperature, so it is sufficient to measure the difference in temperature rather than the exact value of the temperature. The coefficient of thermal expansion α was independently measured using the TMA test.

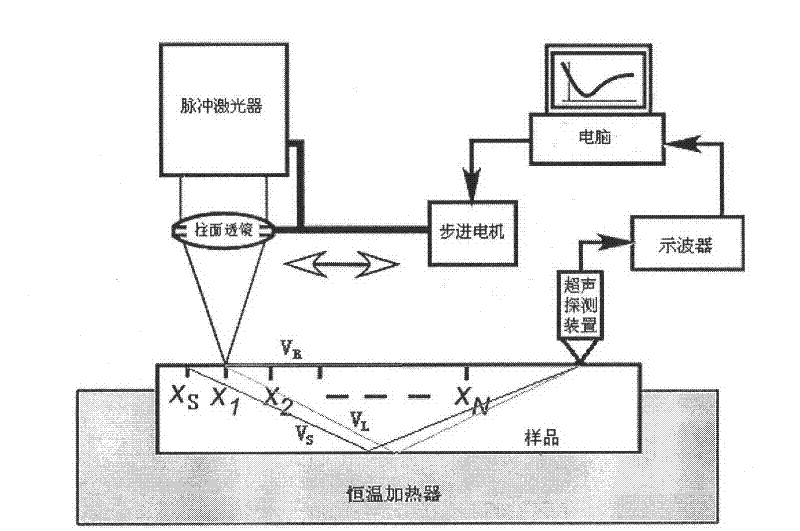

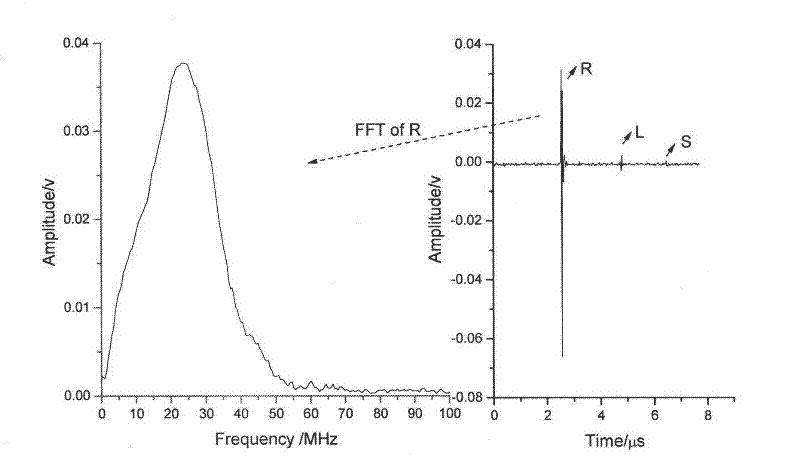

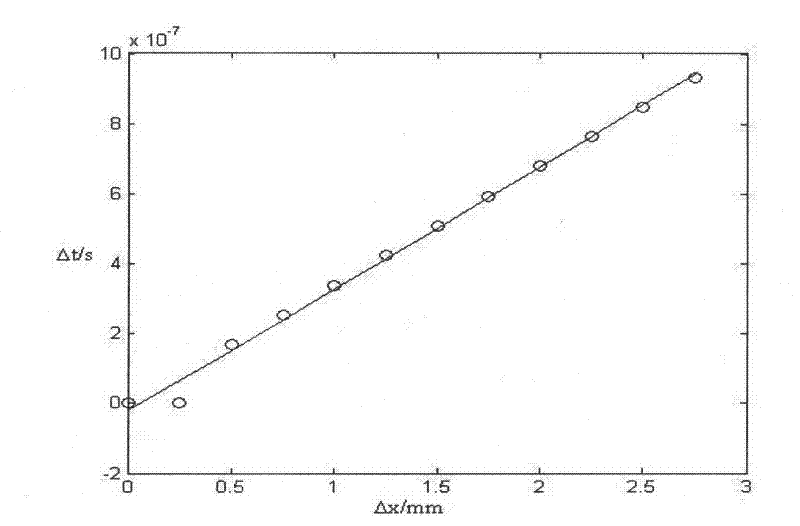

[0041] The specific steps are as follows: First, we measure the wave velocities of all three modes of sound waves at room temperature (22°C). The wave velocity of the SAW is detected at the shortest possible distance (approximately 5-6mm). The speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com