Cooling system of cabinet

A heat dissipation system and cabinet technology, which is applied in the field of server cabinet heat dissipation systems, can solve the problems of temperature rise in the cabinet and device temperature, low efficiency, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

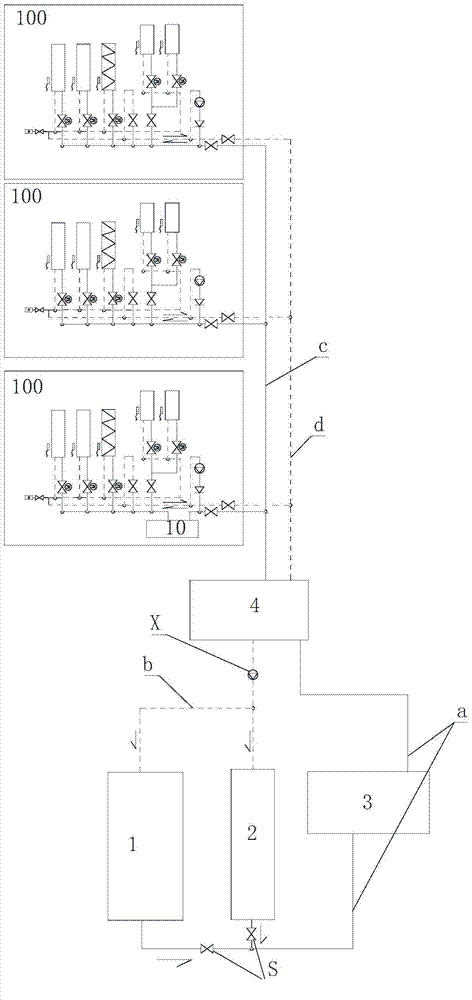

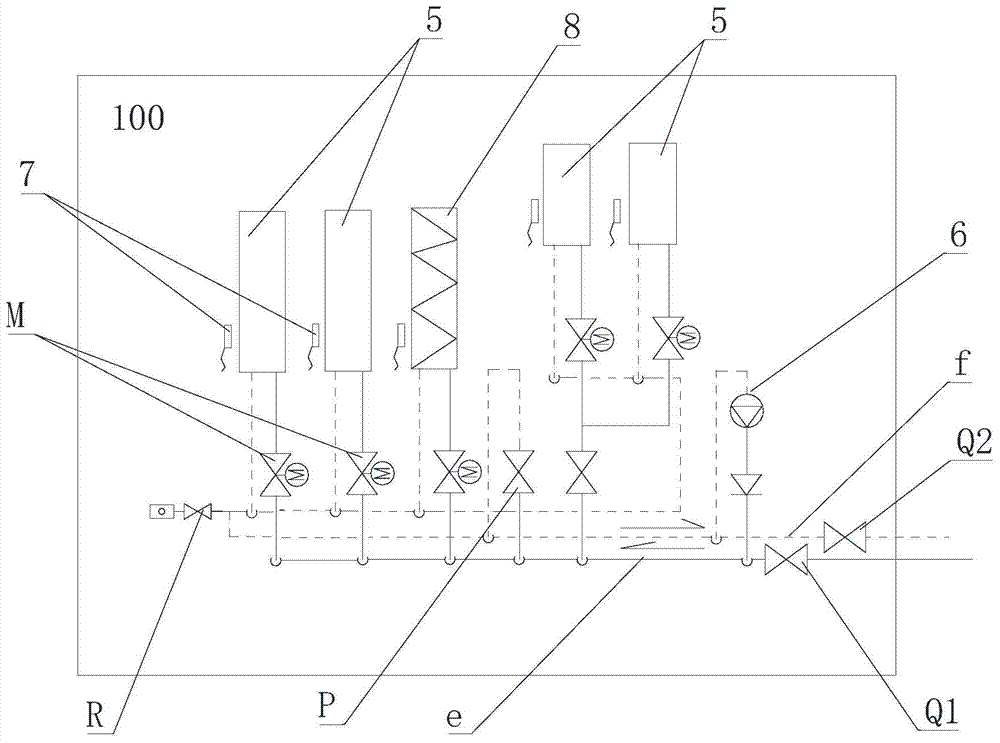

[0031] like figure 1 and figure 2 as shown,figure 1 , figure 2 The pipeline shown by the solid line in the middle is the working fluid inlet pipe, and the pipeline shown by the dotted line is the working fluid return pipe. The refrigerant flows through the pipeline, including phase change or non-phase change fluid. The heat dissipation system includes the external circulation system and the internal circulation system. Circulation system, the outer circulation system includes a cold source composed of a main cooling unit 1 and a secondary cooling unit 2, and a cold storage tank 3 connected to the cold source, and the outer circulation system and the inner circulation system are connected through an intermediate heat exchanger 4. The working medium inlet pipe a of the external circulation system passes through the cold storage tank 3 and is connected to the intermediate heat exchanger 4, and the working medium return pipe b of the external circulation system is connected to ...

Embodiment 2

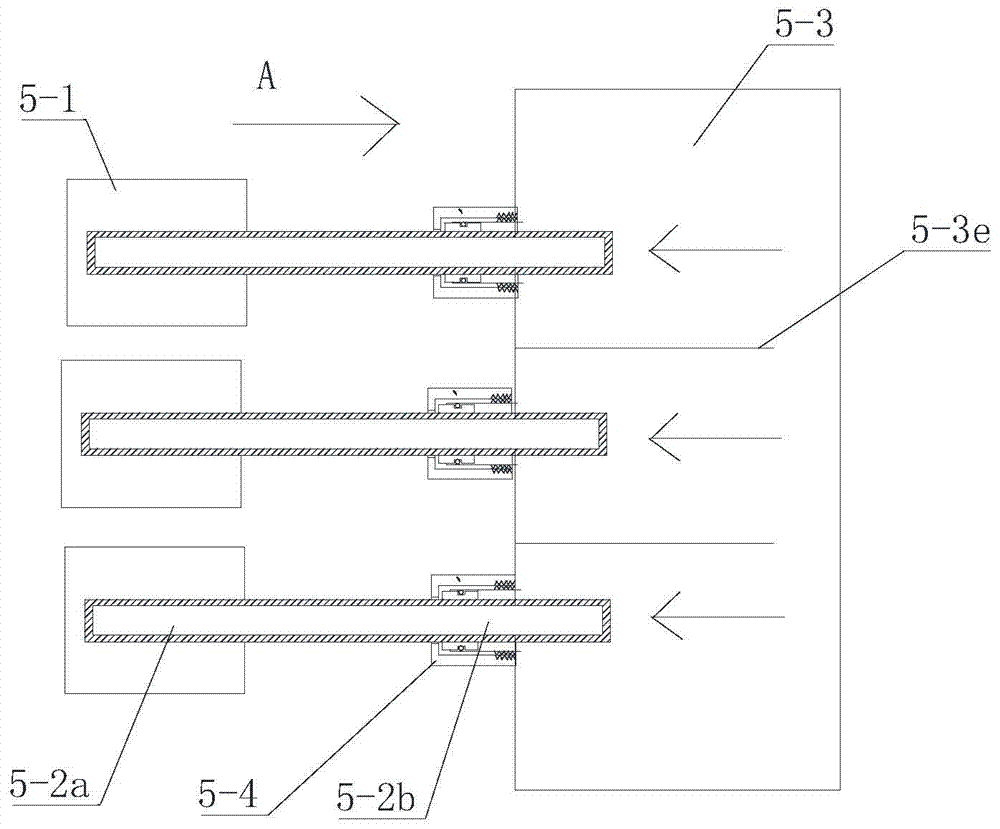

[0037] like image 3 and Figure 4 As shown, the liquid cooling radiator 5 of this embodiment includes a heat dissipation substrate 5-1, a heat pipe 5-2 and a centralized cooling pipe 5-3. The heat dissipation substrate 5-1 is in contact with the surface of the electronic device to be dissipated. The heat pipe 5-2 is connected to the heat dissipation substrate 5-1. Same as the prior art, the heat pipe 5-2 includes a heat pipe evaporation section 5-2a and a heat pipe condensation section 5-2b. The inner wall of the heat pipe is provided with a capillary structure. The heat pipe evaporation section 5-2a is connected to the heat dissipation substrate 1, and the heat dissipation substrate 5-1 conducts the heat on the surface of the electronic device to the heat pipe evaporation section 5-2a for heat dissipation. The condensing section 5-2b of the heat pipe extends into the concentrated cooling pipe 5-3, and is sealed and connected with the concentrated cooling pipe 5-3. In this...

Embodiment 3

[0040] refer to Figure 4 and Figure 5 , the difference between this embodiment and Embodiment 2 is that no intermediate partition is provided in the centralized cooling pipe, the centralized cooling pipe 5-3 is connected to a plurality of heat pipes 5-2, and the heat pipes 5-2 are arranged in a misplaced interval. 3d The cooling liquid entering the centralized cooling pipe 5-3 flows to the cooling liquid outlet pipe 5-3c through the heat pipe radiator 2 arranged in a staggered manner, so that the condensation end of each heat pipe can be cooled by the same temperature of the incoming liquid as much as possible, Guaranteed cooling effect.

[0041] Centralized cooling pipes are used to centrally dissipate heat from multiple heat pipes at the same time, and the coolant circulates in the centralized cooling pipes, which can dissipate heat for multiple electronic devices at one time, reduce the volume of the liquid cooling radiator, and improve the heat exchange efficiency. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com