Solid adsorptive refrigerator

A solid adsorption and refrigeration device technology, applied in the direction of refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of increasing water volume, shortening precooling/preheating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

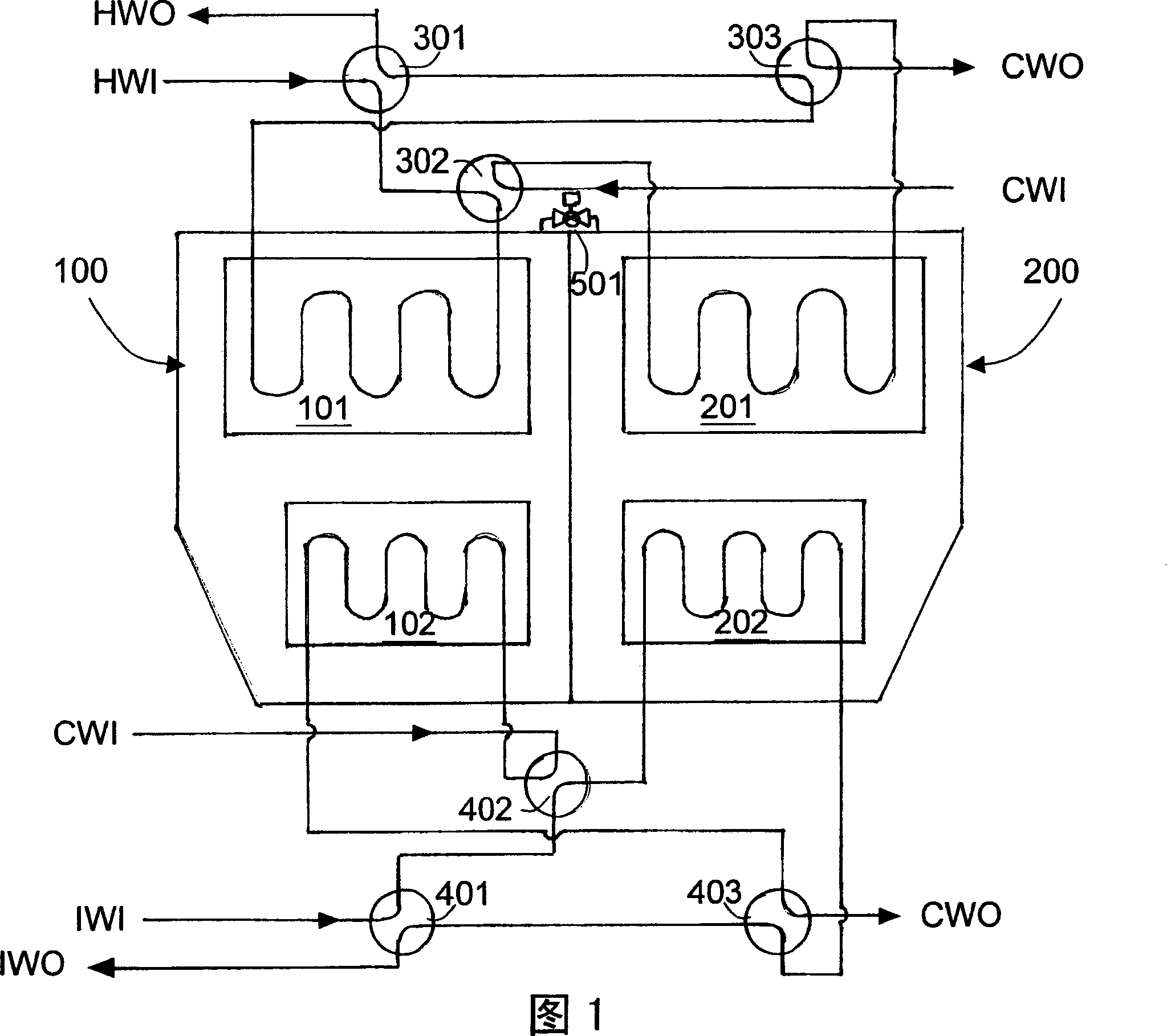

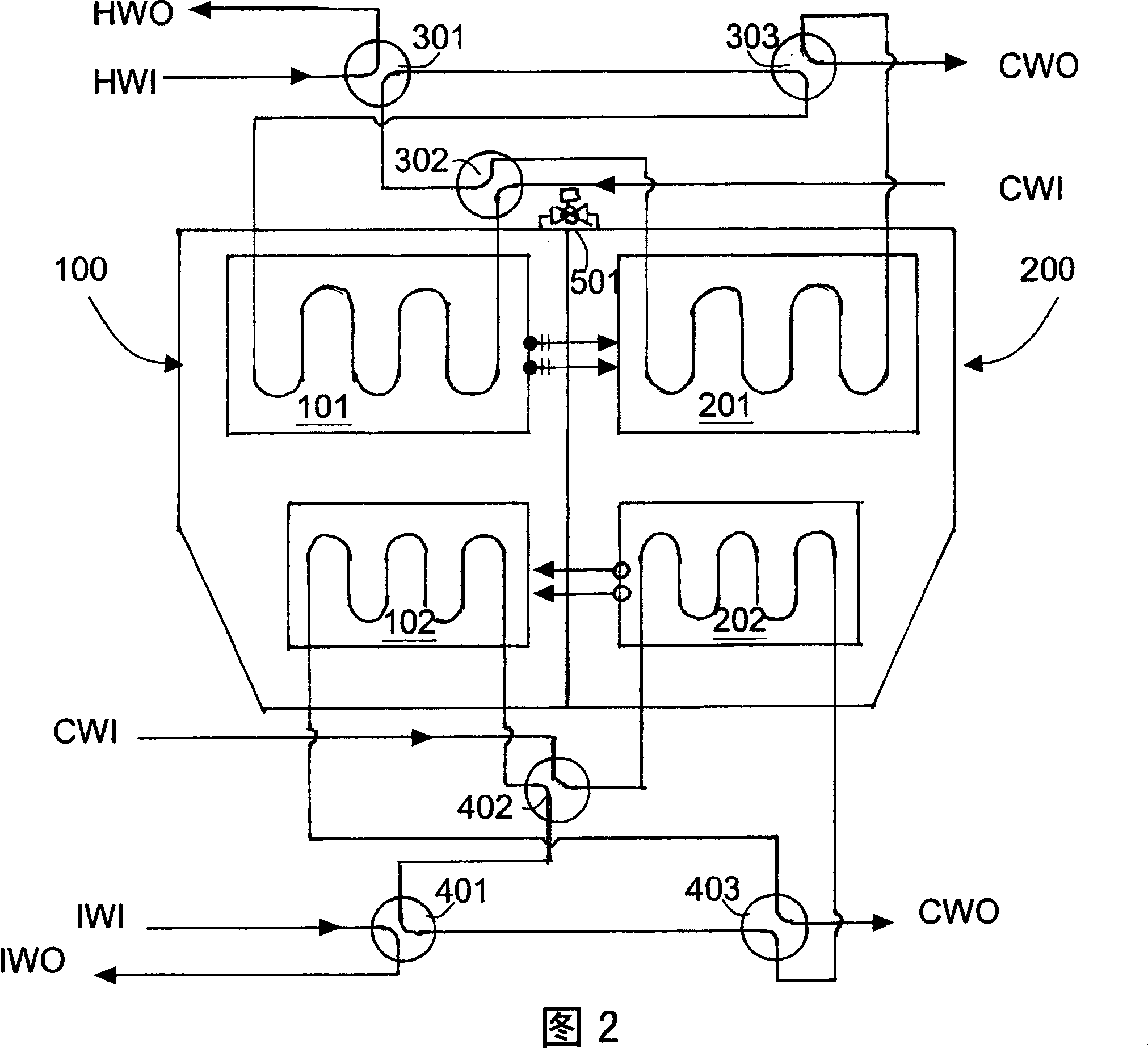

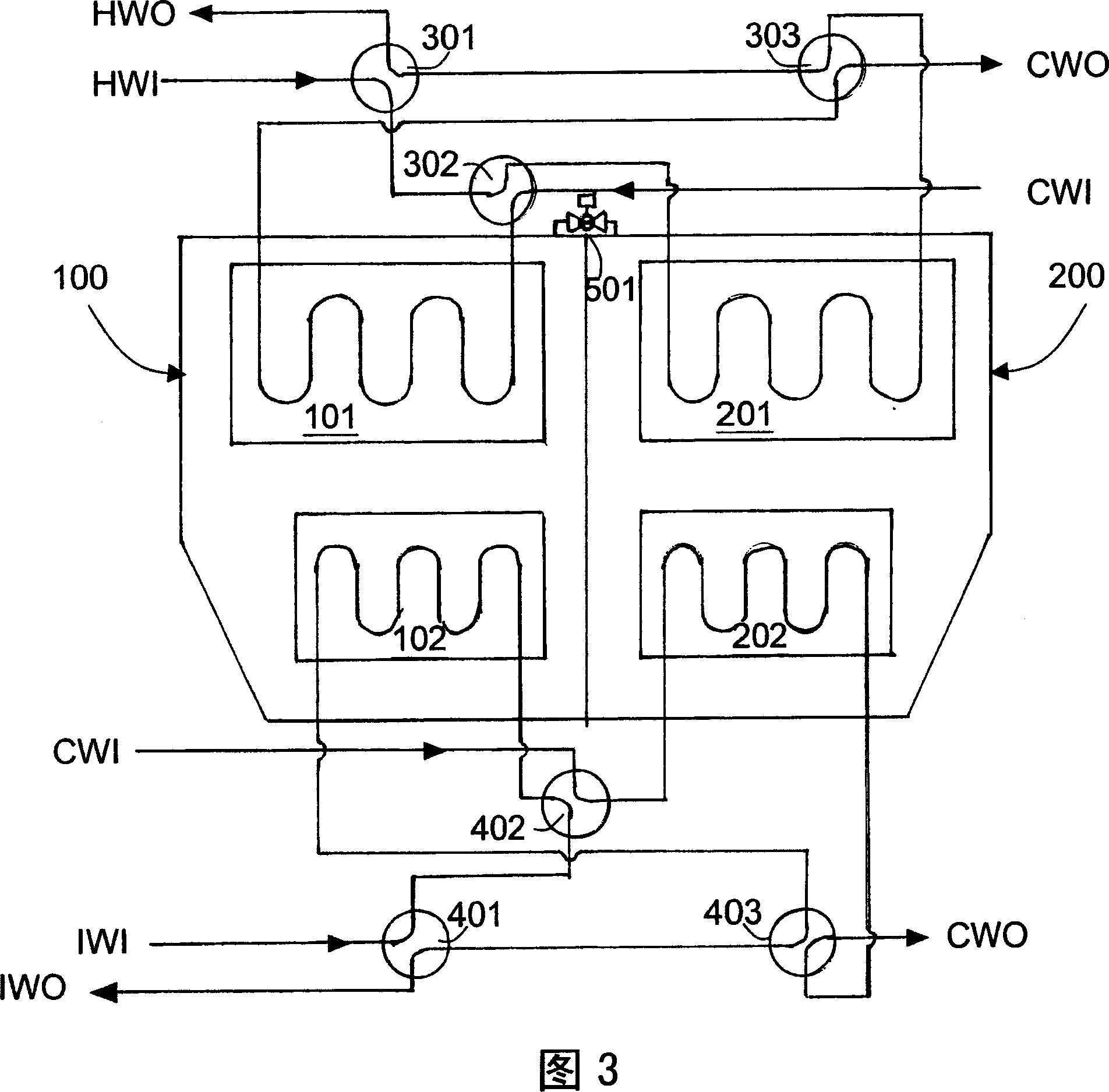

[0041] The present invention is a solid adsorption refrigerating device. In order to clearly show the characteristics of the present invention, a series of refrigeration implementation steps will be described. First, the process of desorption of the left bed and adsorption of the right bed will be described. Please refer to "Fig. 1" is a schematic diagram of the first embodiment of the solid adsorption refrigeration device of the present invention.

[0042] The solid adsorption refrigeration device of the present invention may include: a left vacuum chamber 100 and a right vacuum chamber 200, wherein each chamber is also provided with a left (right) adsorption bed 101, 201 and a left (right) condensation / evaporator respectively 102, 202 and other working units, and each unit is provided with pipelines for liquid circulation, wherein the first switching valve 301, the second switching valve 302 and the third switching valve 303 can be the upper valve group, and the fourth switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com