Calcination process of active lime

A technology of active lime and process, applied in the direction of lime production, etc., can solve the problems of reduced effective utilization rate of lime, unstable product quality, over-burning of the outer layer of raw materials, etc., and achieve high effective utilization rate, fine crystallization, and good heat exchange Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The firing process of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

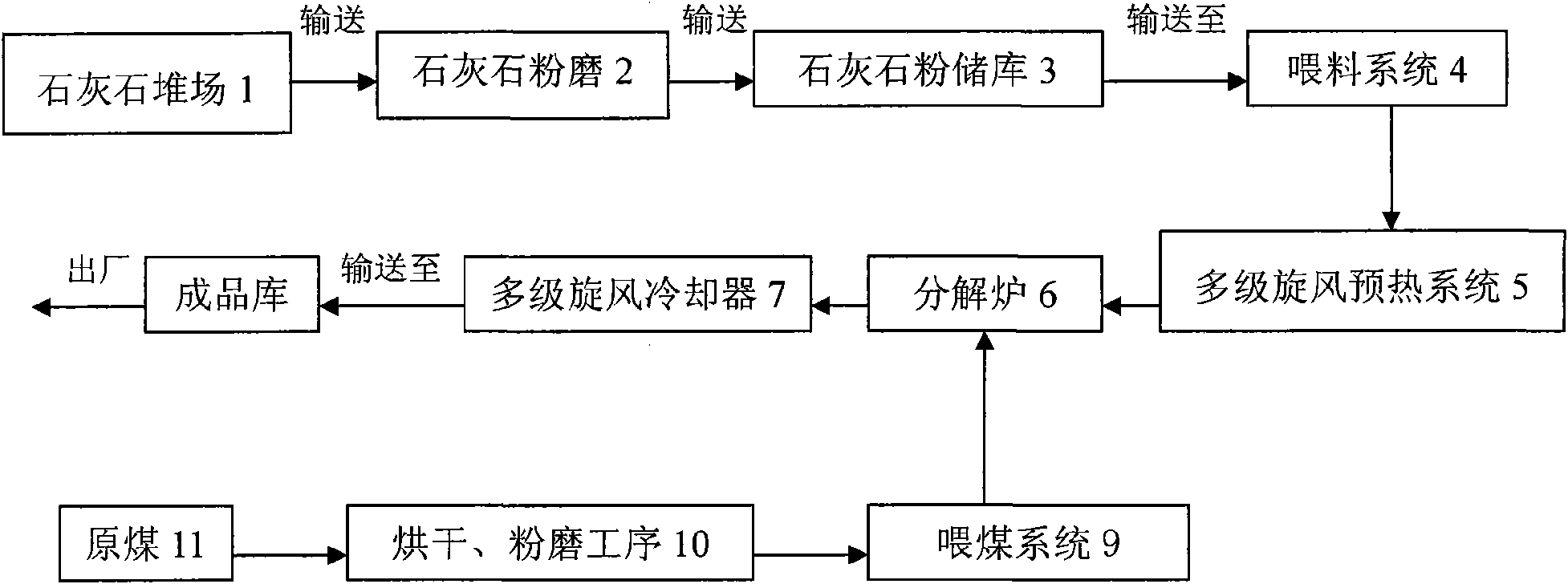

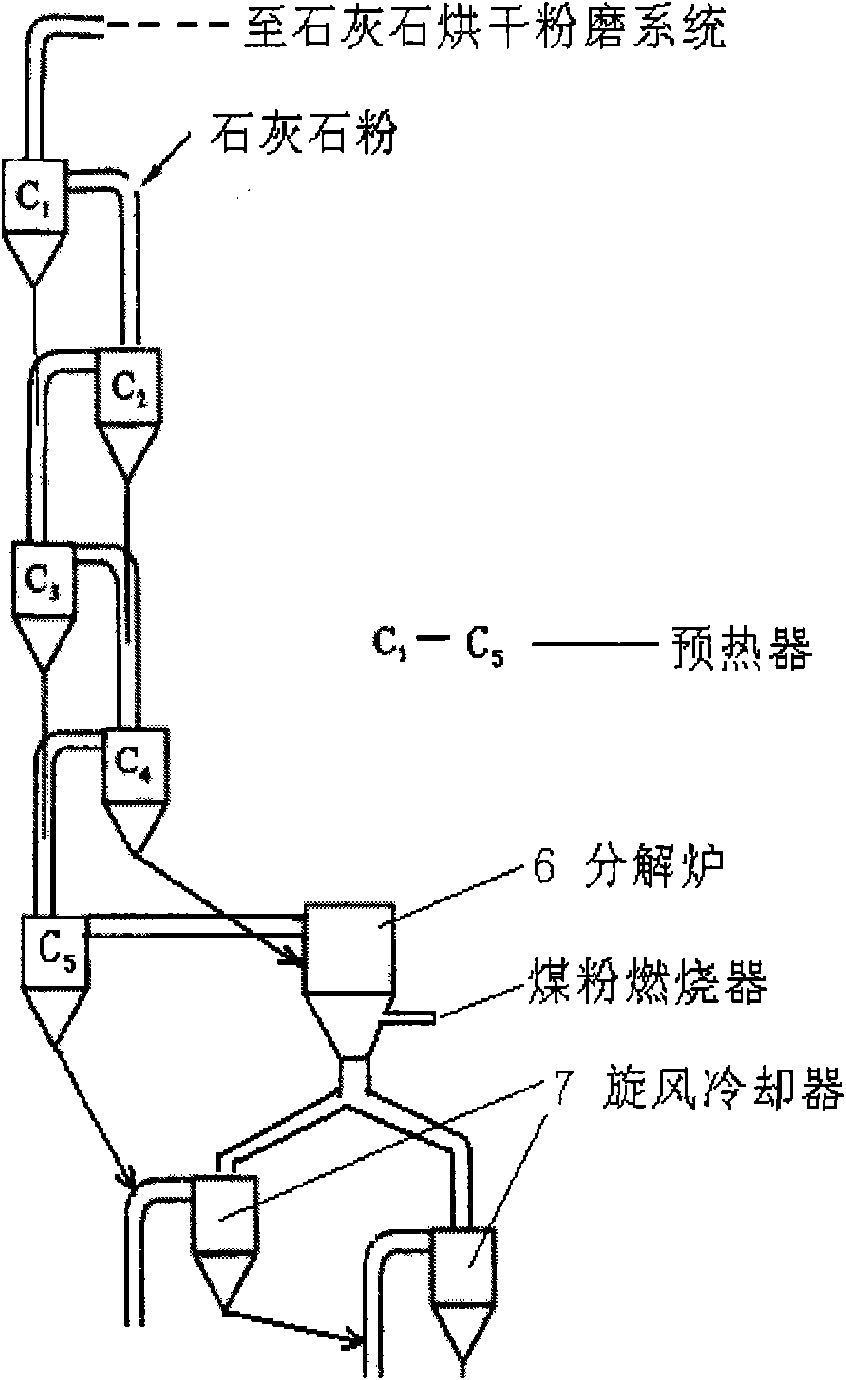

[0014] Such as figure 1 , figure 2 Shown: In order to ensure the stable quality of lime products, after the qualified limestone is broken into blocks, the limestone is mixed and matched and stored in the limestone storage yard 1 through a stacker-reclaimer or other homogenization facilities for later use; Limestone is metered and fed to the pulverizer. The pulverizer adopts conventional tube mill or vertical mill to dry and grind massive limestone (drying heat source is preheated by exhaust gas discharged from multi-stage cyclone preheating system) ; Grinding into 100-300 mesh fine powder. Then it is transported to an inflatable limestone powder storage 3, which not only achieves the storage effect of the material, but also achieves the homogenization effect;

[0015] The firing equipment used for the active lime of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com