Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

A processing method and technology of titanium alloy, applied in the processing field of fine-grained superplastic TA15 titanium alloy medium and thick plate, can solve the problems of low superplasticity, narrow deformation temperature range, large difference in microstructure, etc. The effect of increased refinement and homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

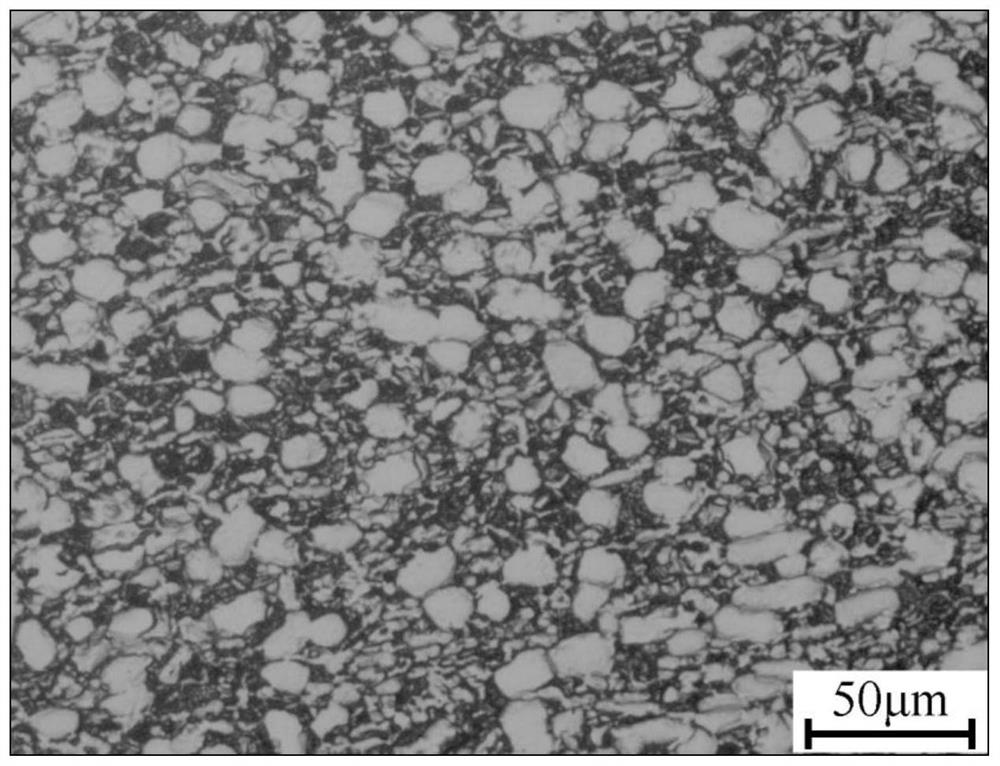

Embodiment 1

[0039] This embodiment includes the following steps:

[0040] Step 1. Melting: According to the design composition of the target alloy, the 0-grade sponge titanium and the intermediate alloy are automatically mixed, electrode pressed and welded in sequence, and then 560mm×2000mm (diameter×length) is obtained by three times of vacuum consumable arc melting TA15 titanium alloy ingots, in which, the vacuum degree in the vacuum consumable arc melting furnace during the first vacuum consumable arc melting process is 0.07Pa, and the vacuum consumable electric arc melting process in the second vacuum consumable arc melting process The vacuum degree in the arc melting furnace is 0.05Pa, and the vacuum degree in the vacuum consumable arc melting process in the third vacuum consumable arc melting process is 0.01Pa. Clean up, and then carry out smooth transition grinding, and the aspect ratio of smooth transition grinding is 1:12, and the depth is 8mm;

[0041] Step 2, billet forging: p...

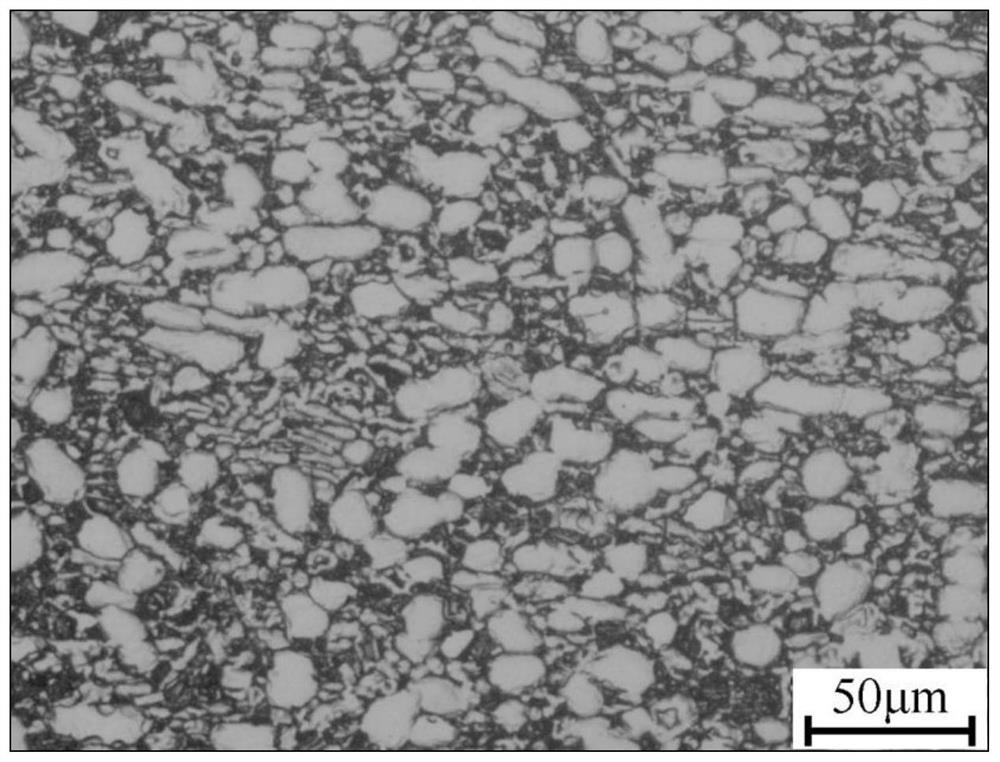

Embodiment 2

[0051] This embodiment includes the following steps:

[0052] Step 1. Melting: According to the design composition of the target alloy, the 0-grade sponge titanium and the intermediate alloy are automatically mixed, electrode pressed and welded in sequence, and then 630mm×2200mm (diameter×length) is obtained by three times of vacuum consumable arc melting TA15 titanium alloy ingot, wherein, the vacuum degree in the vacuum consumable arc melting furnace during the first vacuum consumable arc melting process is 0.08Pa, and the vacuum consumable electric arc melting process in the second vacuum consumable arc melting process The vacuum degree in the arc melting furnace is 0.06Pa, and the vacuum degree in the vacuum consumable arc melting process in the third vacuum consumable arc melting process is 0.02Pa. Clean up, and then carry out smooth transition grinding, and the aspect ratio of smooth transition grinding is 1:15, and the depth is 6mm;

[0053] Step 2, billet forging: put...

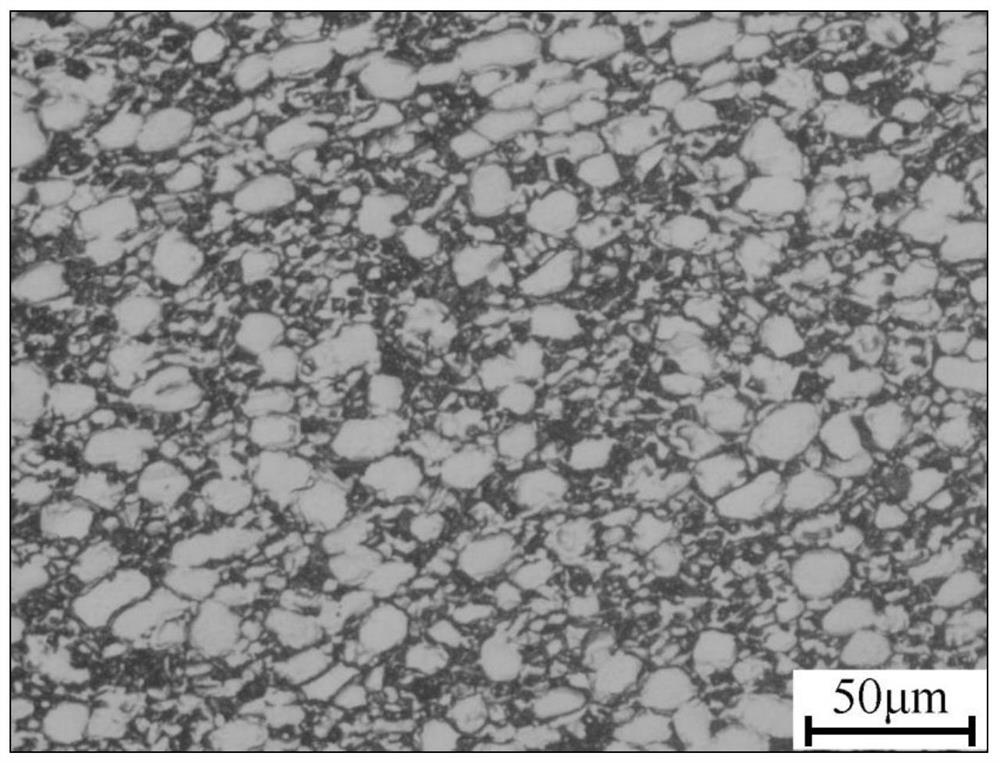

Embodiment 3

[0063] This embodiment includes the following steps:

[0064] Step 1. Melting: According to the design composition of the target alloy, the 0-grade sponge titanium and the intermediate alloy are automatically mixed, electrode pressed and welded in sequence, and then 560mm×2000mm (diameter×length) is obtained by three times of vacuum consumable arc melting TA15 titanium alloy ingots, in which, the vacuum degree in the vacuum consumable arc melting furnace during the first vacuum consumable arc melting process is 0.09Pa, and the vacuum consumable electric arc melting process in the second vacuum consumable arc melting process The vacuum degree in the arc melting furnace is 0.07Pa, and the vacuum degree in the vacuum consumable arc melting process in the third vacuum consumable arc melting process is 0.03Pa. Clean up, and then carry out smooth transition grinding, and the aspect ratio of smooth transition grinding is 1:13, and the depth is 9mm;

[0065] Step 2, blank forging: pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com