Surface treating method of radio frequency passive module

A surface treatment, radio frequency technology, applied in the field of surface treatment of radio frequency passive modules, can solve the problems of troublesome protection, easy oxidation, shortened product life cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

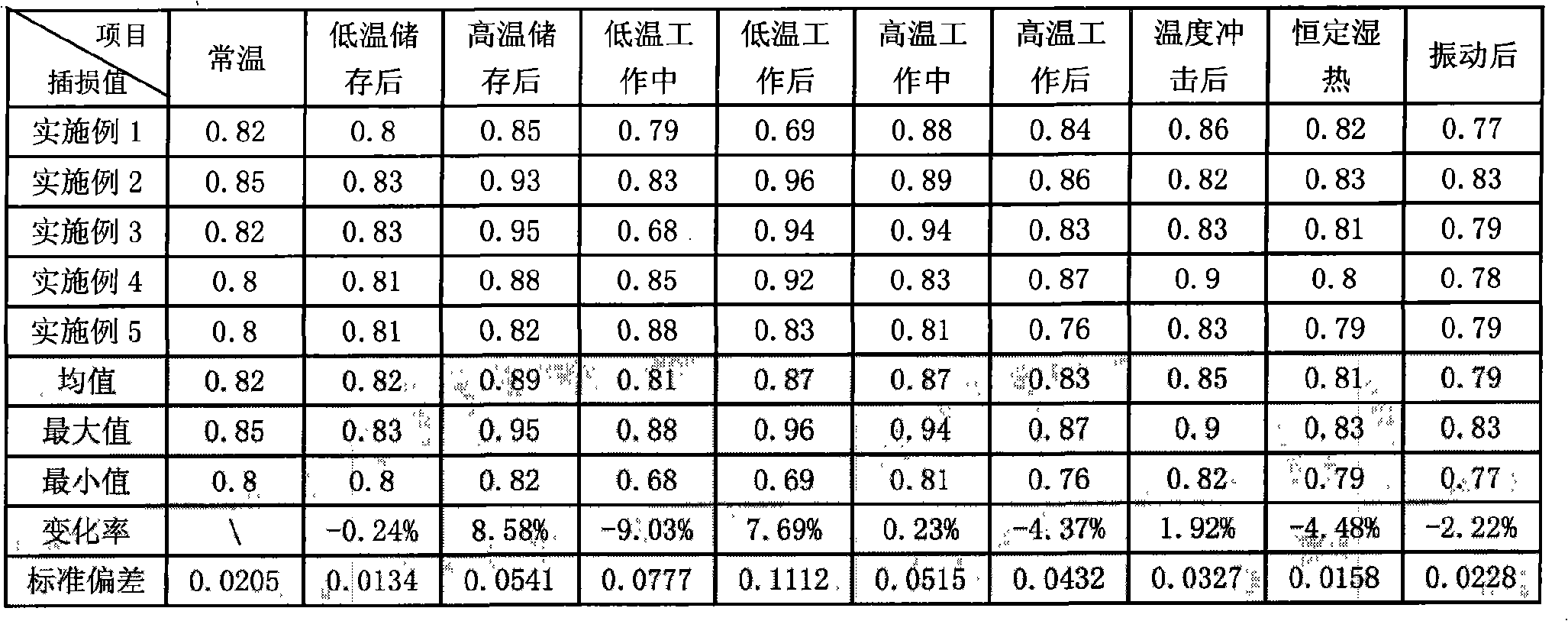

Embodiment 1

[0042] Take the RF passive module to be processed, and after the surface treatment, place the Cu-containing 2+ , Sn 4+ , Zn 2+ The electroplating solution is electroplated under the following process conditions to precipitate a copper-tin-zinc ternary alloy:

[0043] In each liter of electroplating solution: 100g of copper sulfate (40%)

[0044] Potassium stannate (40%) 115g

[0047] Current density: 0.5-2.5A / dm 2

[0048] Temperature: 50-60℃

[0049] pH value: 10-11

[0050] The plating rate is 0.1μ / A·min;

[0051] After the electroplating is completed, a copper-tin-zinc ternary alloy layer with a thickness of about 0.1μ is obtained on the surface of the radio frequency passive module, and then the module is washed, organically protected, hot water treated, dried, and packaged.

Embodiment 2

[0053]Take the RF passive module to be processed, clean the surface, remove dust, degrease and remove oil, and wash with water; then perform acid activation, primary zinc immersion, dezincification, and secondary zinc immersion treatments, and wash with water; at the same time, the pretreated RF The surface of the passive module is first plated with a dense and uniform layer of active copper (4-8μ) to improve the bonding force between the final electroplated copper-tin-zinc ternary alloy layer and the surface of the module, and to improve the conductivity and magnetic permeability of the product Rate; and washed with water; then, put the copper-plated RF passive module into the Cu-containing 2+ , Sn 4+ , Zn 2+ The electroplating solution is electroplated under the following process conditions to precipitate a copper-tin-zinc ternary alloy:

[0054] Per liter of electroplating solution: 125g copper sulfate (40%)

[0055] Potassium stannate (40%) 139g

[0056] ...

Embodiment 3

[0064] Take the RF passive module to be processed, clean the surface, remove dust, degrease and remove oil, and wash with water; then perform acid activation, primary zinc immersion, dezincification, and secondary zinc immersion treatments, and wash with water; at the same time, the pretreated RF The surface of the passive module is first plated with a dense and uniform layer of active copper (4-8μ) to improve the bonding force between the final electroplated copper-tin-zinc ternary alloy layer and the surface of the module, and to improve the conductivity and magnetic permeability of the product Rate; and washed with water; then, put the copper-plated RF passive module into the Cu-containing 2+ , Sn 4+ , Zn 2+ The electroplating solution is electroplated under the following process conditions to precipitate a copper-tin-zinc ternary alloy:

[0065] Per liter of electroplating solution: copper sulfate (50%) 90g

[0066] Sodium stannate (40%) 112g

[0067] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com